Everything posted by Bullet

-

Head gasket replacement

-

New Exhaust

You know you guys are right on the money. I made the exhaust switch at the exact same time I installed the twins and noticed how much quieter the exhaust was while idling. At the time I just thought my new exhaust is much better than my old one...never once thinking about the effect of the extra turbo. But now I can see how that would make the difference.

-

Head gasket replacement

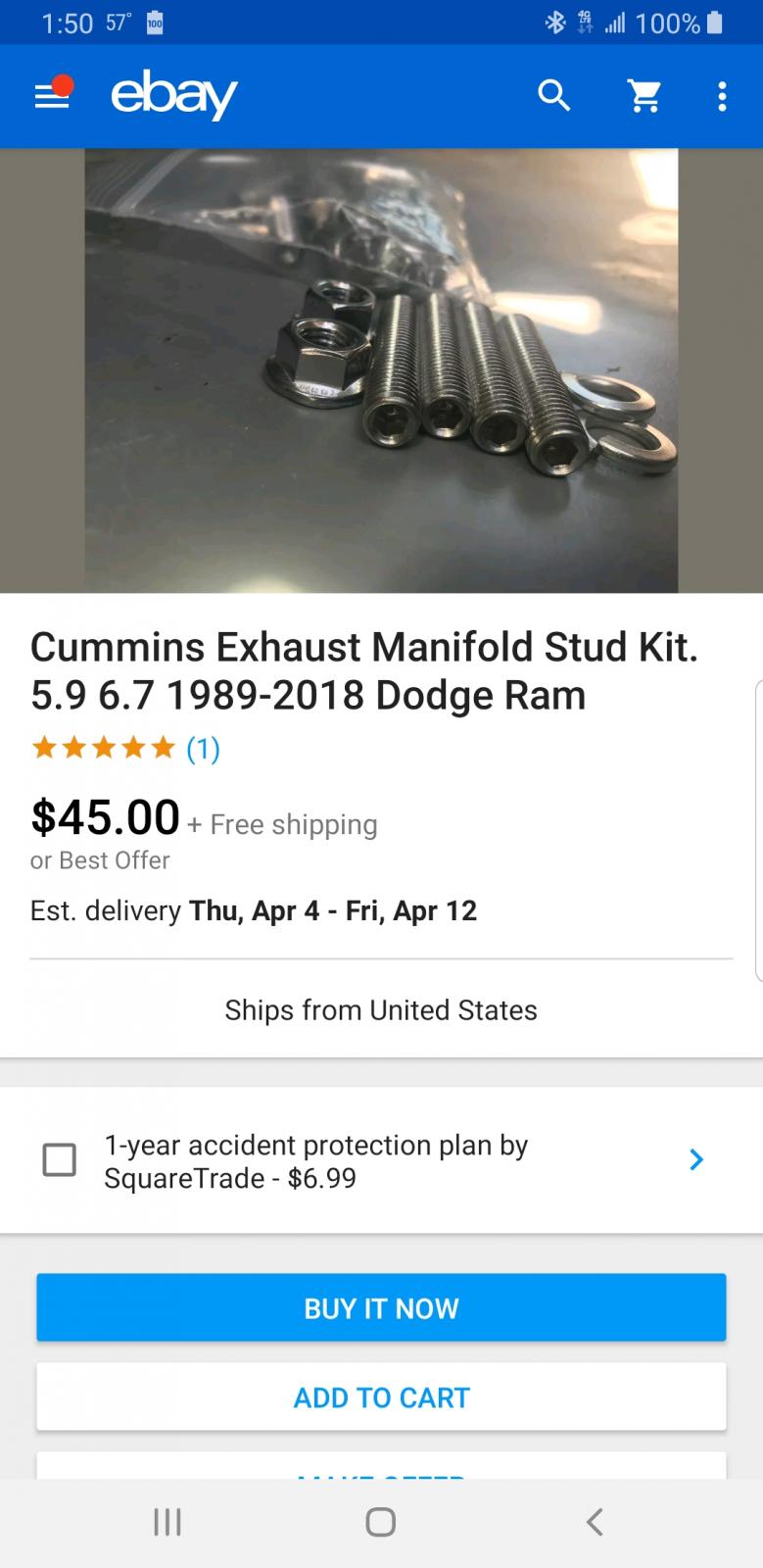

Lol...I completely agree. I got my stainless studs, nuts and washers in a kit for our engines off ebay for $45 delivered to my door. It was worth it for easy reinstall. See pic for listing...

-

Fuel Pressure High!

If you are having to clean it out so many times you probably haven't got it all out yet. I don't understand why you would have debris in the line at all. I never had to take mine back apart from install. I would definitely blow out the entire bypass line with compressed air to guarantee it's clean. Also test your bypass valve by hand when you get it out. Push on the white disc with a small screwdriver to make sure it is moving and depressing the spring with a little pressure.

-

Spindle Nut Torque Specs

I had to get a cheater bar on the torque wrench and then got all my neighbors to jump up and down on it to get it there. 280lbs is alot!

-

Fuel Pressure High!

If your pressure was fine and then spiked like that...something is blocking the overflow back to the tank or you have the check valve backwards. I would pull the overflow line at the Tee before the check valve and blow with air hose to see if the line is clear. Also call Richard and see what he has to say. He will answer his phone afterhours at a decent time. That kind of pressure could blow the top of your fuel filter canister off which is a big mess. I would fix it before driving again. To make sure you have the check valve in correctly look into both sides of it. You will see a spring on one side and solid white on the other. The spring is on the tank side and the white is on the engine side.

-

Head gasket replacement

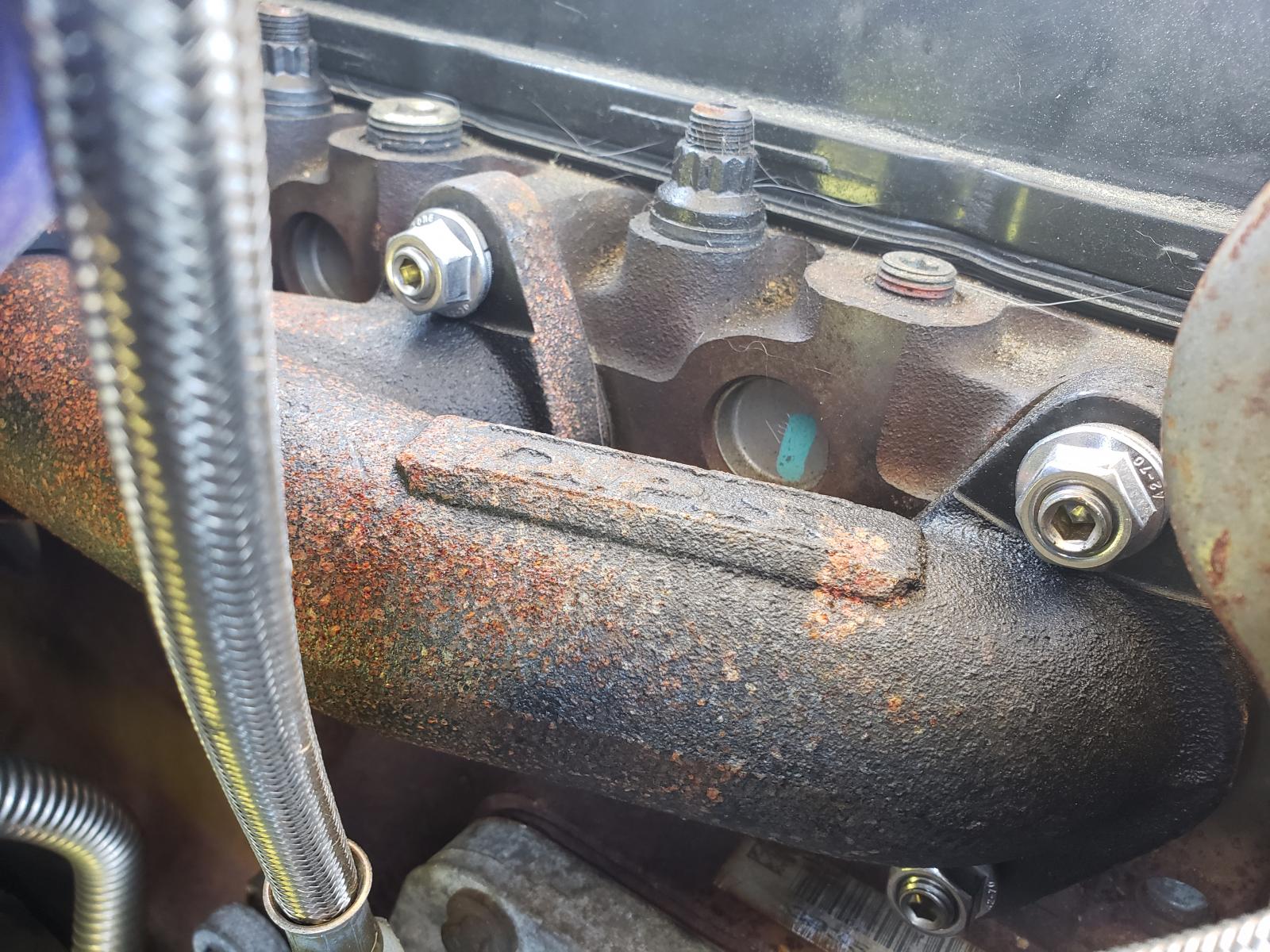

The metal strips are a bolt locking mechanism to keep the bolts from backing out like exhaust manifold bolts are famous for doing. I mangled mine too getting them off. I changed from bolts to stainless steel studs with SS locking nuts and SS lock washers so I didn't have to use the strips again. Haven't had any trouble with them backing out with the different set up. You should either put some new ones back on or switch to studs. If you use studs you don't have to use those useless spacers you had to pull off with the bolts either. Studs also make it a hundred times easier to put the manifold back on too cuz they hold the manifold gaskets in place and easy to hang manifold on studs. I did use high temp anti-sieze when I put the studs in the block. I also used my engine hoist when I did mine...so much easier. Good thinking!

-

New Exhaust

That might be the case but if it is I do not understand the science behind why that would make a difference. I thought it might be because my tailpiece sticks out a little further than my last one did and my last one droned a bit. This one is a Diamond Eye stainless and my last one was aluminized...both with mufflers and both 5".

-

Front end

I'd be happy to discourage from going big lift and tires. It's very expensive and a real pain in arse. I have had to lengthen drive shafts, lengthen brake lines, reconfigure emergency brake, made my own jack stilt cuz my 30" industrial jack just wouldn't cut it...and that doesn't include the hours of labor removing and replacing every suspension, steering and alignment arm on the entire truck. And if that's not enough to discourage you...I spent $3.5k in parts and $2k in wheels and tires. Keep in mind that I did it all myself so not a dime was spent in labor...except for the driveshaft lengthening. I wouldn't do it again.

-

Drive shaft U joint at Rear diff Yoke

I replaced with all greasables and pump em up every oil change. Haven't had any problems with them and I give em hell fairly often. Also my drive angle on my rear shaft is an unhealthy 12°...even worse on the front shaft at 15°. I have 7 total on the truck including front axle shafts. It takes a few minutes to get em all greased but it gives me something to do while 3 gallons of oil is draining out.

-

New Exhaust

I have a stainless 5" stainless steel muffled with no cat and it is quiet at highway speeds and any other speeds. All I can hear is whistles from the turbos and some mechanical sounds from under the hood...absolutely no droning. Got it from DAP.

-

Choosing The Right Fuel Lift Pump For My Needs

If you never ever want to deal with a lift pump issue ever again during your ownership of the truck...the only way to guarantee that is to go belt driven mechanical. Cost is about $500-600 and there are about 4 different brands to choose from. It's also the only style of lift pump that will supply more pressure as throttle increases rather than less. Mine supplies a constant 18psi at idle and 20psi at higher throttle levels and has never varied from that. I carry an extra belt with me that can be changed anywhere anytime in 5 minutes and belts are recommended for 50k miles and I was given my extra belt as condition of the sale. There are some pretty good electric pumps out there but they all will eventually fail. They have great warranties which cost you nothing to replace them but you still will eventually have to replace them and risk a VP44 or be down until you get a new one. Their warranty will not cover a new VP if it dies because of a failed warrantied electric pump. There's has been plenty of bad press about all brands of electric pumps but none to be found on mechanicals...that's what made my decision for me.

-

Help broken axle U-joint

Cheers!

-

can i use v10 tank on 12v?

I am currently using a 5.2 tank on my 24v. Had to use my diesel lid or top but the rest of it is the same.

-

Help broken axle U-joint

Make sure the assistant stops for beer as well...it can help ease the pain.

-

Front end

That's not gonna work. You're gonna have to extract the broken part of the bolt and then see what you have left to work with and then proceed from there. Others have already commented on how to do it. Go back and read comments from others on how to.

-

Front end

If you are at stock height it's not a big deal to drive without one. If you are lifted the swaying effects are multiplied the higher you are lifted and therefore less safe to drive without one.

-

Front end

Better say a prayer too...cuz the last time I pulled mine out they were rusty to the point of rotting threads. Had to run a tap back up in it and get new bolts and applied some RTV for anti-corrosion purposes.

-

Front end

What he said ^

-

Front end

It's your tortion bar or anti-sway bar. Keeps the truck from swaying to one side during a turn or evasive maneuver. So I would address it as soon as you can from a safety standpoint. You can completely remove the entire bar and drive it until you fix it to keep it from hanging down and possibly causing other issues. I have driven my truck without one before. The truck just felt top heavy and not as sure footed and the suspension felt softer. Not as safe feeling but could be driven carefully if you had to.

-

Front end

I believe so...that was the idea behind all the work and expense anyways. My truck is just a play toy and only pulls a Bullet which is a very light boat. It is not a daily driver. It has been cut in half, shortened and welded back together and is lifted with oversized tires and lots of power. And like Mopar1973Man said those kinds of enhancements will shorten the life of many stock components. Hence I bulletproofed/upgraded pretty much everything everywhere. It was expensive but I have saved alot by doing all the work myself. If you are keeping your truck stock then they are pretty reliable and somewhat economical with the exception of a few weak points...and parts are fairly cheap as well. Where you can save the most money is doing any work yourself.

-

Front end

4th gen steering rack w/grease zerts, steering box support bracket, drop pitman arm, XRF ball joints, huge Timken bearings, bigger 35 spline lockable hubs, axle u-joints, front driveshaft u-joints, bigger 35 spline outer axle shafts, adjustable long control arms and brackets, adjustable track bar and bracket, steering stabilizer, coil springs, shocks, and shock towers. That's just the front driveline, steering and front suspension upgrades.

-

Front end

I completely agree with you that the parts not beefy enough for our trucks and that the 4-link/panhard bar is a great design. It's the Y-steering rack combined with the poorly supported steering box where the poor design lies. Like most I have had to address the short comings of our ends. Everything I replaced, which is everything replaceable, has been beefed up from a strength (thickness) and design aspect how it should have been done in the first place. I even drilled and tapped for grease zerts in my new steering rack, went to repackable bearings and lockable hubs, beefy long control arms, steering box support, and XRF ball joints as extra efforts. Everything up front is now serviceable/greasables and stout. I don't expect to ever have another issue up front.

-

Front end

No worries...that's what makes these forums work is different opinions on ways to do things. We'll have to agree to disagree. There is plenty of resistance to show you what you are looking for with the wheel off the ground and don't have to kill yourself trying to move a tire on the ground. I don't have a shop full of mechanics to assist anytime I need it...I'm a one man show. It's a one man job with the wheel off the ground. Same applies for checking play in ball joints. My opinion here is work smart, not hard.

-

Front end

Mostly it's because of poor design. The steering box is not supported well enough and the Y-steering rack is a bad design too. The track bar design leaves alot to be desired as well. The steering rack can be upgraded to the 4th gen T-steering design and the steering box can be better supported by an aftermarket brace that attaches to each frame rail through the pitman arm shaft of the steering box. It's a good idea to replace the track bar with aftermarket design also while you're at it. Otherwise it's just ball joints and unit bearings. To check for any wear (or play) in the steering rack and track bar, jack up the front wheels and put your hands at 9 and 3 (relative to clock) and work wheel back and forth. If you have movement look to see what is moving and you have found your wear. To check ball joints and/or unit bearings put your hands at 12 and 6 and do the same. Bad unit bearings can usually be heard/felt while driving too.