- Replies 27

- Views 9.3k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 6 posts

-

JAG1 4 posts

-

dripley 3 posts

-

Rotax3006 2 posts

Most Popular Posts

-

Yes, this is correct. Actually, it is not odd. There is a fixed displacement vane pump inside the VP44 injection pump. This vane pump rotates at the same rpm as the VP44 and pro

-

First off, nice looking clean truck. I went through 3 Carter left pumps and read all the problems people were having with their electric lift pumps so I installed a mechanical Fuel Boss li

-

The 14 psi is where the return valve is fully open. It has a bypass that always lets some by all the time. I cant remeber at what pressure the valve starts to open. Maintaining a 14 psi minimum just a

Hi folks. I am interested in settling on the right fuel transfer pump for my 1998.5 24V 2500. My engine is stock. I have no plans to increase horsepower or torque. I have 157,200 miles.

I bought the truck last August. Right before I bought it, the VP44 had failed and been replaced in June. However the lift pump was not replaced. I decided to dig in a learn a bit about this known problem. I purchased a fuel pressure test gauge and checked the stock Carter pump. Readings were ok for the stock system, but a little down. I decided to change it out ASAP with another stock Carter pump at that time. I wanted to experiment and track some results. With the new Carter in I was getting 10 psi at idle. Dropping down about 6.5 to 7 psi pulling a steel hill. I proceeded to install a digital ISSPRO fuel pressure gauge and drove in that state it over the past winter.

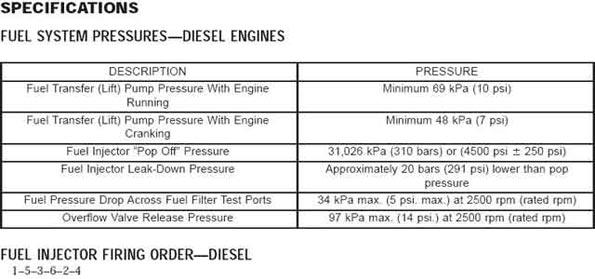

Over winter, I continued on to read about various high performance fuel lift pumps. I bumped into the Airtex or Herko fuel lift pump. Priced at about $70 so I decided to try the Herko. I put it in about a week ago. Fuel pressure at idle is 16-17 psi. Pulling hills drops to about 9-10 psi. A considerable improvement over the stock Carter. Hi-way speeds on flat ground the Herko makes about 14 psi. My understanding is the check valve inside the VP44 opens at 14 psi allow for proper full cooling of the pump electronic circuit board. Is this correct? It seems odd to me that the Bosch needs to see 14 psi to cool, yet Dodge engineers chose a max-10 psi at idle, fuel pump.

I own a 23 ft travel trailer I plan to tow. If the VP44 does indeed need 14 psi for proper cooling, I suppose I should be looking at a pump that can maintain minimum 14 psi at all times. Am I on the right track here? Do I really need to be looking at these expensive AirDog or FASS pumps at $600 to $800? Seems pretty pricey for a stock HP truck. I understand that saving the VP44 is the idea here, as they are big bucks. Looking at the Gino's catalog here as I type this, they offer a mid-level upgrade. The FASS High Performance Adjustable Fuel Pump at $464. I assume if I go this route I'll also need to upgrade the fuel suction lines.

It's been interesting learning about the various pump options. I have already spent $200 screwing around with pumps and learning. I do my own work and do enjoy it. Thoughts and tips settling on the right right lift pump for me are appreciated. Thanks. Keith

Edited by keithb7