Everything posted by Mopar1973Man

-

2002 Dodge Ram 2500 - Things to do.

Ok... My truck went to down after a hard run here locally. Trying to turn around on the highway and out run a semi-truck. Finally blown the head gasket. Not bad but it weeping oil out the front. Still starts and runs. Yes I know most like the smallish turbo (drive pressure) is my problem and need to upgrade. Right now with all that is going on my 2002 is going to remain down for some time and let me fix it right. I know I got to pull the head and get it inspected for sure then reinstall. I'll leave wire tap off till later when upgrade turbo can be had. Already had a nice chat with @dieselautopowerabout it. Like I'm just about got the 2006 Dodge up and running and will be installing the new +50 HP injectors in that today and changing the oil. I'll be back in function today for business. Next thing I need to find a full lock set for my truck the driver side door lock is so wore out even my factory orignal key (spare unused) will not open the door. I want to find a door lock set for both doors and the ignition lock as well as a set. After having @Wet Vette car broken into I'm going to be looking for a good alarm for my truck and kill switch to prevent it being stolen. Also gotta look for one for Eileen's car too. Want to pull the interior apart and power power the carpet out and reinstall. Looks awesome when its done because it looks like brand new again. I've bought new seat covers 3 months ago and never install them. Including new steering wheel cover. I want to fix all the weird quirky things in my truck that have been over looked. So I'll keep this post going on the stuff I'll be doing.

-

Mopar1973Man Meeting Diesel Auto Power

Yes sir... We are back home safe and sound by 9pm last night and unpack just enough to get to bed. Already up bright and early just mere 29*F degrees here Brrrr... Just like I left Salt Lake in a snow storm. Go back to Twin Falls and it got warm like 65*F yesterday actually had the A/C on. Yeah you got the spelling right... @Wet Vette is Eileen. My first job today is to install those injectors.

-

02 ram 3500 nv5600 pilot bushing

I've used both clutches supplied by DAP... Valair Dual disc (early version) in my 2002 Dodge. Now I've bought the Valiar Dual Disc Quiet towing clutch which is also awesome design and better than my 2002 clutch. Then before that I've bought the South Bend Con OFE through DAP. All came with seal ball bearings for the pilot shaft. Even the clutch I did in @Jthor 1995 7.3L Ford Powerstoke came with the old school needle bearing from NAPA. Previous flywheel the dual mass spring broke and the pilot bearing was fine just drying out on lube. The clutch still had some life yet but since the flywheel upgrade to a 13 inch so did the pressure plate and friction disc. All new there and butter smooth! Oh just a heads up 95 Ford F-350 manual transmission should have ATF in it. Surprise some got smart like me and ditched the ATF and put in quality GL-4 lube!

-

Gen 3 track bar conversion

This is where like oversized tires and leveling kits fall into... When any leveling kit it used it will steal the caster out as the axle is forced downward more. Typically a adjustable lower control arm is wanted. Then like track bars if there is a leveling kit installed then the thrust angle is typically wrong as it pulls the axle toward the passenger side. This is where you need a adjustable track bar. As long as you remain stock height and stock tire sizes then all stock parts can be used.

-

Salt Lake City, Utah - Crime!

While I was there in Salt Lake City Utah @Wet Vettehad here car broken into and stole my camera. First off my fault for leaving in the car. The broke out the passenger rear glass and reached in and took the camera. The hotel we were at caught it all on camera and got a clean view of the persons face. Police report filed and taken care of. Working together with Eileen we manage to get the hotel to cover the broke window with tape. Then cleaned up most of the glass in the car and in the parking lot. Got a hold of the insurance company and got them to send us to the SafeLite Glass shop less than 2 minute walk away. By 11am we had the car fixed and head to DAP to go pick up my injectors. I'm sure glad I didn't have those injectors in the car too. It's not the broke glass or the fact my camera is gone the biggest thing is some one violated our space without permission. The camera can be replaced, so can the glass. Oh for all you that have vehicles with car alarms you may or may not know the alarms will not go off if you brake the glass and reach in. As in Eileens Hyundai the alarm was armed and never went off. No glass break sensor. So as long as the thief didn't open the door it stays quiet. After learning this we will always leave the cab of the vehicle EMPTY before going shopping or staying at motel anymore. The Hotel said it took less than 30 seconds he broke the glass and hauled with my camera. Again I know its my fault for being stupid and leaving in the car. Good fact is Eileen's insurance will NOT cover for the camera replacement.

-

99 auto immediately after refreshed injectors stalls when placed in D or R

Absolutely true. Do the W-T ground wire mod and do the PCM protection fuse and most of your problems will go away. Skip all the noise filter mods, tin foil the charge lead, etc. Yank all that stuff off and just do the W-T ground mod once done that problem is over for a lifetime.

-

Fixing my daily tune

Best to give you a flat level area after the defuel zone. On the fuel map figure out you common cruise pressure including climbing grades and highway travel. Old vs new with a cruise zone. 0-87 - 85 1-88 - 89 2-89 - 93 3-90 - 97 4-91 - 100 5-92 - 100 6-93 - 100 7-95 - 100 8-97 - 100 9-99 - 100 10-101 - 100 11-102 - 100 12-103 - 104 13-104 - 108 14-105 - 112 15-106 - 116 16-107 - 120 18-108 - 124 20-110 - 128 22-112 - 132 24-114 - 136 26-116 - 140 28-118 - 144 30-120 - 148 Now set the wire tap to start at 12 PSI and then it will ramp up with the CanBus and there is no smoke because the turbo is already spooled 12 PSI before dumping the boosted CANBus and the wiretap so it will get up and ...

-

Mopar1973Man Meeting Diesel Auto Power

@dieselautopower @Quadzilla Power @Jthor I finally made the first step of meeting vendors for the first time. Happen that @Wet Vettewanted to catch up with her older daughter. Being I was only 30 miles from Layton UT I had to go meet Jacob Kidd in person. It only a 8 hour drive over to DAP from my home. Most would say this didn't happen unless there is photos right? Big shocker for most of you... Starting from the left, myself Mopar1973Man, Yup no more pony tail on me... Then Marco From Quadzilla and then to the right is Jacob Kidd. Just behind Jacob is Micthell all you can see him ducking and hiding. Other face to the far right I've already forgot the name. (shame on me) I still hard time keeping name and face right... Then under my arm is my new set of +50 HP injectors of my 2006 Dodge. @Wet Vette was trying get photos of the rest of the crew... Some were trying to hid from camera view but she managed to get them. But you looking at the call center area for DAP. I did get to go into the shop which I couldn't take any photos back there. I will say @dieselautopowerhas a awesome injector shop and crew back there. Jacob was showing me around how CR injectors are tested and scored. Some of the internal parts with in a injector. For a fair size shop they do handle all injectors in house for our Cummins trucks. Highly impressive injector shop. Then wondered out back to look in the warehouse. He's got other work stations out there for cleaning up cores and getting them inspected and ready for building again. Then wonder through rows of pallet racks full of new parts, some racks where full of cores (injectors and turbos). I'm really surprise even Jacob consider waste management for chemicals and cardboard. Most of his cardboard is ran through a shredder to turn it into a packing material for shipping again. Cleaning and testing fluids wise he's managed to keep waste to low levels too. Oh, yeah that friendly voice most of hear as we call DAP. Lexi (forgive me if the spelling is wrong) she right there to greet you as you come in the door. Really nice after all these years of calling and her asking what I needed then tell her its "Mopar1973Man" calling again. The crew here is super awesome all very dedicated to getting the job done and staying focused. All I can say is Diesel Auto Power is here to provide all the needed parts for our Cummins trucks... Even the Fords and Chevys too. Being I just bought @Jthor injectors through DAP for his 1995 Ford 7.3L diesel +50 HP injectors. Then just before leaving the exhaust brake came for a customer for a Duramax I've got to install. Give them a call they are here to help you... DIESEL AUTO POWER (801) 927-4600 QUADZILLA POWER (801) 872-5472

-

Fixing my daily tune

Lower pop pressure more ADVANCED the timing. Hence why I went to 320 bar making it slightly RETARDED which now you can stack more timing. Starting at 13 and going up by plus 5... 13, 17, 22, 27... Start there. The 13 degrees will give awesome spool up being you popped low you could start at 12 and work up.

-

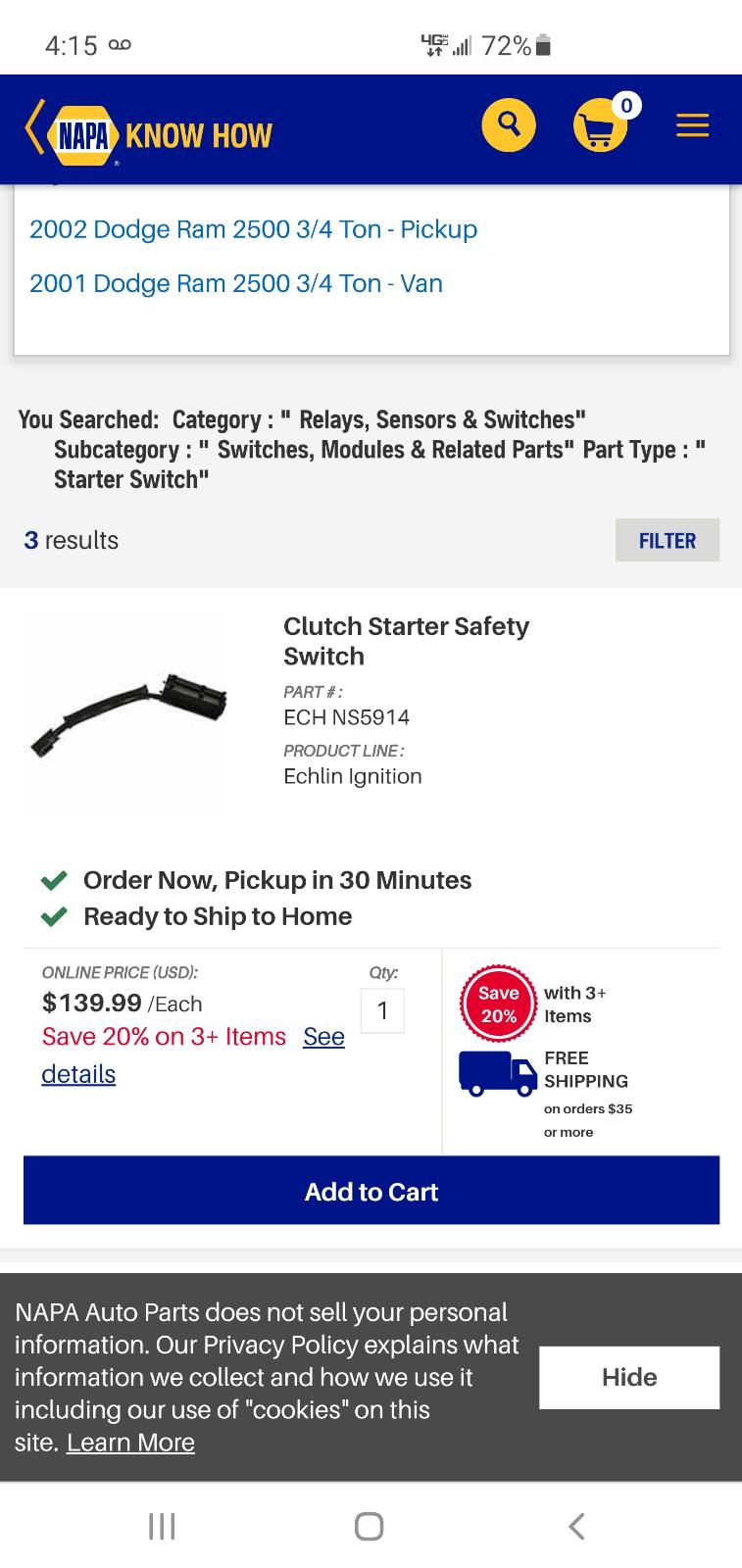

Nv4500 getting harder to get into gear

Pull it out and inspect. Mine I caught before the contact finally quit. Yup got a RockAuto switch after looking up a NAPA price. I was getting random hit miss starts.

-

Nv4500 getting harder to get into gear

-

Nv4500 getting harder to get into gear

Clutch safety switch is cheap through Rock auto. For info purpose still zero problems with Mobil 50 SAE Transmission Fluid still a very good option for heavy towing.

-

Dap 7x0010 injector problems

Pop pressure of the injectors or dragging torque converter. Another member by @pepsi71ocean had the same problem found out the injectors were popped to low. Like my 7 x0.0085 injectors SAC had issues with stalling swapped back to VCO problem gone. Like my current injectors 7 x0.010 are popped at 320 bar with VCO nozzles.

-

Truck shakes at 55-65mph, Grinding/vibration when coming to stop as well.

Nv4500 transmission 3.55 gears 245/75 R16 tires 66 MPH is exactly 2k RPM 82 MPH is exactly 2.5k RPM. Final to the ground is 3.69:1.

-

Possible ECM issues

Simple and main computers ground do not go to body metal in stock form. ECM, PCM, and VP44 are all on the passenger ground cable. After the W-T mod the computer will not be on the passenger battery but the gear near the VP44. All other subsystems ground to body metal. Like ABS grounds near the driver side headlight.

-

Squeal and jump

Get some fluid from both the transmission and transfer case the one with glitter is the bad one.

-

Squeal and jump

Actually it does still turn while unlocked. The shaft rotates slower but still it will turn. Does on my 1996 Dodge with CAD axle.

-

Possible ECM issues

Next time I see you @JAG1 I'll drop an manifold bolt in your intercooler.

-

Possible ECM issues

Don't have to do the other grounds because the W-T mod will relocate the grounds. That would be a waste of time cleaning up the old ground to relocate to a new place which will force you to create a new clean ground.

-

Nv4500 getting harder to get into gear

My video is still around on the youtube channel. Just hang the whole assembly and pump hard and fast in on the slave cylinder and then slowly let it out. Slower the better that way you don't draw air back down from the reservoir.

-

99 auto immediately after refreshed injectors stalls when placed in D or R

There was another member here with the exact same issue. DTT transmission with stalling. Everyone swore the torque converter was the problem. Nope. He had his injectors sent back to DAP and had then popped for 325 bar IIRC. The stalling issues STOPPED completely. The pop pressure was too low making the injection event too early and the engine could not recover quick enough so it stalls. After @pepsi71oceanupped the pop pressure his stalling quit. Might take ot him and ask him for more details of what he's done. Like my truck I had a set of +75 HP 7 x 0.0085 SAC injectors after a long run down the interstate and get to Boise my truck as a manual would stall coming to a stop again this set was popped to 305 bar. After have those swapped out and went back to VCO injectors and popped at 310 bar all was well again but the life span was a mere 75k miless and started to misfire after that. This when I built the 7 x 0.010 VCO injectors popped at 320 bar.

-

Nv4500 getting harder to get into gear

Most pre-bled kits will cost you extra. Then there is roughly 1 and 10 chance that it work out of the box. So many times I've gotten pre-bled and have to pull the system back out and rebled the master and slave over again. The problem is with shipping and handling did any air travel back into the master? etc. The last one I got from Valair worked out of the box but late... I had to pump the pedal several times to work some small amount of air out. This is installed on the 2006 Dodge. I did one for Russ truck last winter and it was a prebled as well. PITA to get adjusted to prevent hyper-extending the throw bearing. If you do it will ruin the pressure plate fingers. Still got OE styled on my 2002 truck and manually bled every time no issues. 431k miles.

-

Automotive Gear Lube Study

I've never been a huge follower of oil studies. Typically the results go to the big brand names, AMSOil, RedLine, etc. There is other oil studies done here that people gone a long ways without big brand oil. Take to @cajflynn 1.3 Million miles and Never used any synthetic oils ever not to mention changed oil every 20k miles. Then there was @dorkweedthat ran over 84k miles on Walmart SuperTech Universal Diesel Oil 15w-40 and tested every 7k miles. Not to say the tested oils are bad but don't discount others. Seeing members running past 1 MILLION MILES mark and not using high dollar big brand oils is proof enough for me... Like @cajflynnjust Chevron Delo 15w-40 and Fleetguard filters nothing special. Like myself I'm either Chevron Delo or NAPA (Valvoline) for oil 15w-40 and NAPA filters right now.change interval of 10k typically. We've got another member here right at 950k miles now...

-

99 auto immediately after refreshed injectors stalls when placed in D or R

Popped too low in pressure id your rising above 800 RPM at all. All Cummins ISB engine idle at 800 RPM. The only way to increase idle speed is to drop the pop pressure below 290 bar. Then to show the specs even Dodge FSM specs say 293 bar is bottom. Like my OEM stock injectors tested out at 260 bar at 120k miles. The idle was 850 RPM. Span plus or minus... 4500 - 250 = 4250 4500 + 250 = 4750 PSI to Bar 4500 PSI = 310 Bar stock 4250 PSI = 293 Bar 4750 PSI = 327 Bar Proper injectors should hover with +/- 10 RPM from 800 RPM. The engine load should be like 7% to 10%. Show you reversal. I'm 7 x 0.010 injectors (+150 HP) and popped at 320 bar. Cleaner, no smoke, slightly less flow but idles exactly 800 RPM +/- 5 RPM. Engine load when new was 13 to 14% this shows the VP44 working a bit harder to get pop pressure. Now with nearly 100k miles on the injectors I'm down to 6 to 7% engine load but rock solid at 800 RPM idle. NOTE: There is members that had injectors loose over -10 bar after running about 20k to 40k miles. If you popped too low near the lower margin then it will be a very short life of the injectors. Like shops popping for 300 bar only last like bare 50k to 75k miles and already popping too low.

-

Nv4500 getting harder to get into gear

Your is done. Worn out... Should not be signs of rust and moisture which you have this master is cooked and no longer good. While you at is order a new clutch safety switch from RockAuto. Once your up around 400k miles that switch will die.