Everything posted by Mopar1973Man

-

98.5 fluids..

Had to share on of the locals wanted the diff and transmission fluid changed. I did find another transmission fluid for NV4500. It is a GL-4 75w-90 lube. Limited slip rear end with 75w-140.

-

Quadzilla 4K tuning

Might also read my finding on oil temp.

-

2001 Altenator Charging WOES

I opted away from fuses. If you have something go wrong and it blows you got to carry a few extras. At least a resettable circuit breaker you can at least reset many times over. I've seen the old 140A stock fuse blow and some just rotted away or cracked. Fun is when you look and the fuse looks fine but actually its cracked.

-

Truck died second version

When I'm at home at the PC everything is fast... Here I'll dive in a help... Fuse 12 Now you can see everything that is runs.

-

Low Boost

There is a jump swittch inside the Quadzilla for the MAP sensor. I'm not sure which way is which but one way is early MAP sensor and the hang the jump of one pin is the other series of MAP sensor.

-

2001 Altenator Charging WOES

Like myself and @mr.obvious both have the circuit breaker and mounted behind the passenger batter neither is having an issue. Same manufacture as well I've already seen 106°F summer day in traffic and no issues as of yet.

-

E-brake/ parking brake return spring???

Rear parking brakes are what pull the pedal back up. This means you need to adjust out the slack.

-

2001 Altenator Charging WOES

Need a another test shop. New test stands report max voltage, max amperage, max AC ripple, and even a sine wave of the ripple. Most NAPA stores have a quality test stand.

-

Truck died second version

Done. Split out.

-

Stock EGT temps

Now here comes the fun of pulling the gear then re-index the pump and test drive for a week and then do it all over again till you hit the hot spot. I've been at it on my truck for over 6 months building this tune. At least VP44 is easier to set timing over the p-pump. Still in the end game the timing is correct the fuel usage will be down and the oil temp should be -10°F below coolant temp.

-

When the smarty touch display dies, how do you get another one?

Smarty screen have a bad USB port in the Smarty side. Known to have the solder joint breaking. You'll need to box it up and send it to Smarty for repair. This is a known issues.

-

Truck died second version

First off that what the site is all about is coming together and fixing the problems we find. We all share information and figure out what the issue is and then come to a solution that is fair permanent. Lets start basic with error codes and the fuel pressure while your driving the truck down the pavement. (idle, cruise and WOT). Test for power at the lift pump plug after bumping the starter.

-

Diff switch from 3.55 to 4.10

Roughly 4,400 pound in the front, and 2860 on the rear axle. This is empty truck no cargo. Your truck might be a bit more.

-

Diff switch from 3.55 to 4.10

That was max capacity. Front axle was inflated to 65 PSI The Rear was like 45 PSI. Ran good.

-

Dead throttle pedal, weird trans stuff..

AC noise you need the W-T ground wire mod. Then for the dead pedal it could be APPS sensor failing check for a P0121, P0122 or P0123 code.

-

Diff switch from 3.55 to 4.10

I've had a set of tires that made by Black Lion (China) and were a 235/85 R16 tires that were G Load Range (3,750 pounds @110 PSI). There is a wide range of China tires that have super high rating but most would never give up the US name brands for a China made tire.

-

Brakes, power steering

I used NAPA economy pads all the way around and cleared 180k on the first batch of brak pads, then over 200k on the second batch of brake pads. Rotors lasted over 380k miles before I replaced them. The economy pads have way less metallics in the pad and dont eat up the rotors.

-

Stock EGT temps

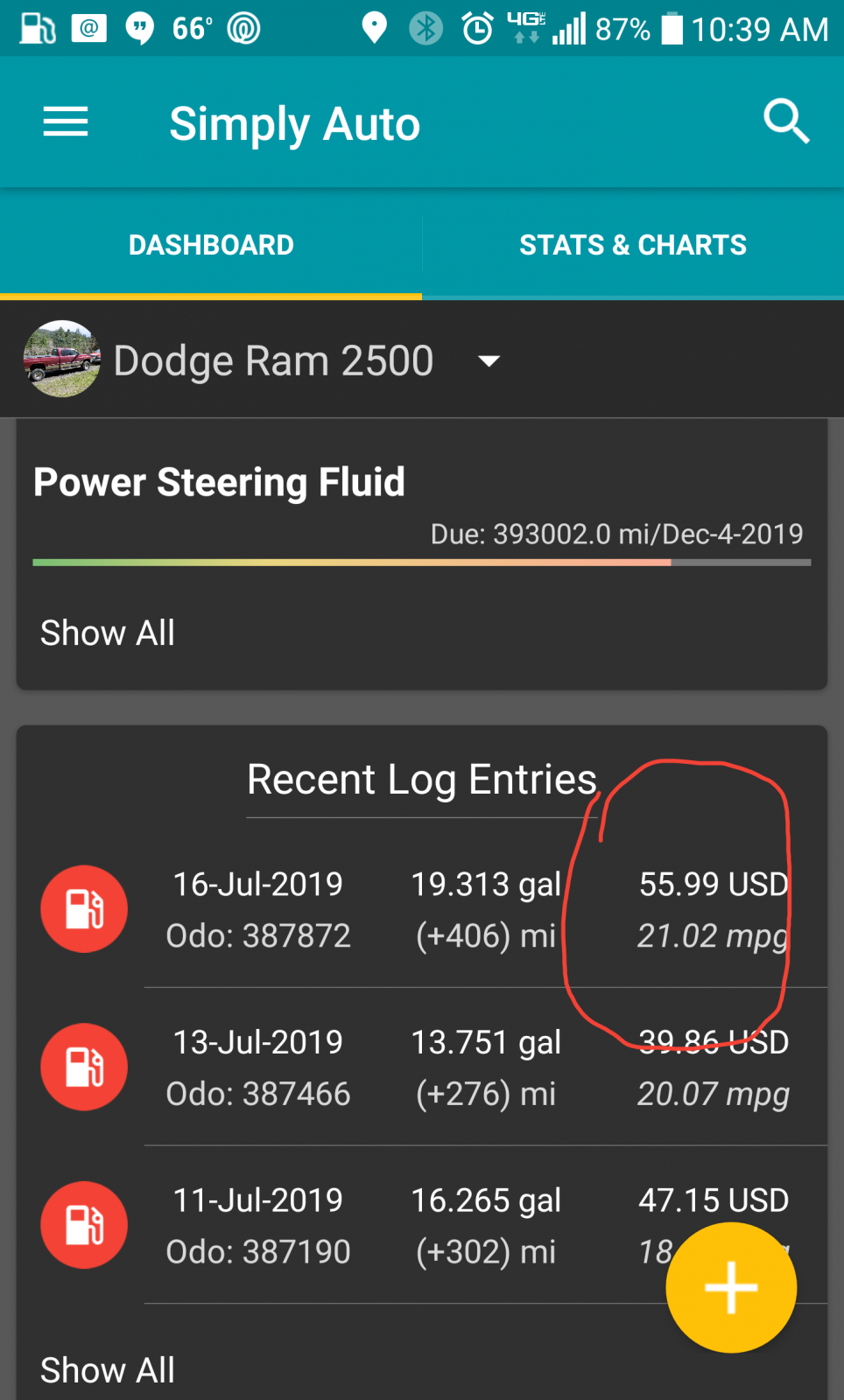

On our truck this is not true. Late or retarded timing puts more flame out the exhaust port and spools the turbo. Too advanced will heat soak the coolant jacket around the cylinders. This can bee seen by using the trans temp sender in the oil test port on the oil filter. Typically the oil temp should be about -10°F below coolant. Over advance the timing the oil temp can rise to +10°F above the coolant temperature. Now I did a test run and over retarded the timing and pull the oil temperature down to -22°F below coolant. The power was way less and MPG's dropped out. Now my latest update on my Econo Tune has this in the tune and cross the 21 MPG mark with 150 HP injectors. I'm one of the rare few. More here... Then the tune...

-

Diff switch from 3.55 to 4.10

The Hankook ATm 245/75 R16 are S speed rating (112 MPH).

-

fan clutch help

Exactly what I'm say like @dripley saved big time buying from part supplier and ended up with the same OEM part without paying for the mopar logo.

-

Truck died in traffic, will idle but dies with throttle (7) DTC codes

Both can be had at DAP. @dieselautopower Maybe he get you a quote for a package deal... You never know...

-

fan clutch help

This why I ask who made the part this way you can still save a ton of money and buy that manufacture elsewhere. For example if OEM is a Murray then buy a Murray from Rockauto or NAPA... Then your not buying the Mopar Logo or Cummins Logo.

-

Coffee And Morning Thoughts for the day.......

Nope. Very quiet. Low traffic, No police presence most of the time. Salmon fishing was a bust. Steelhead fishing was a bust. Now everyone is trying rafting that seems weak. Just quiet out here.

-

fan clutch help

Still I've got to still ask the question who made the OEM? I know both Mopar and Cumins do NOT manufacture fan clutches. Still would like to know who is manufacturing the fan clutch.

-

Coffee And Morning Thoughts for the day.......

Electronic delete I love because you just saving all the part for the emission test. "Lookie, see all my parts are there." Truck passes. Electronically it does nothing. Coffee wise I do a double shot of half and half and a teaspoon of sugar. Pour that coffee down my throat. EGR can just lay there and look pretty. I wouldn't want all that carbon pumped back into my engine.