Everything posted by Mopar1973Man

-

Ready to do a fuel system

AirDog / Raptor has had a troubled past where the owner of the company sold it and the new owner changed up the design attempting to make more money. What this did was created several issues that reduced lifespan of the pump and motor. Like I've got a Raptor sitting on the shelf with a bad motor shaft because the seal ate groove in the steel shaft. Now if you didn't know FASS and AirDog are a Father and Son thing. Father owns AirDog and the Son owns FASS. Kind of like a family feud of sorts. I can say that I've talked to the Father about AirDog and what was happening during the high failure rate. He assured me that he was going to get the owners to comply with the contract of the company. There is a long legal background with AirDog between the Father and the new owner. Lot of people wanted to go back to the old school mechanical pumps like the 1st Gen and 2nd Gen 12V had. The belt driven pump is the closest thing to getting there with good performance. There is a factor that has not seen the test of time. I know the mechanical pump is the farther mount pump from the fuel tank. No pump is designed to suck fuel a long distance. This why Electric pump are favored in some cases. Even Dodge went to installing the pump in the tank to shorten the distance and get the pump back to pushing fuel not sucking the fuel.

-

Ready to do a fuel system

Mean this? https://www.glacierdieselpower.com/i-1206-98-5-02-gdp-dodge-ram-mk-7-big-line-kit-heated.html One filter is nearly half the cost of an AirDog or FASS pump kit.

-

Airdog filters only?

On a BHAF I've been known to drill a hole large enough to insert the filter minder in the head of the filter. The OEM filter minder was designed in inches of water column not inches of mercury.

-

Center Console/Armrest

Dang only one port. I'm in the process of looking at re-doing my accessories in the cab. Right now I need 3 USB ports 2 Amp minimum. Basically 2 cellphones and I want to change up my Garmin from a cigarette lighter charger to a Mini-B USB cord. I've been looking into 12V USB port and solutions.

-

I think my ECM took a crap

Nicely done cable setup you got there.

-

REAR Vibration

@KATOOM has the best suggestion. I would set it up in a driveway or quiet parking lots so if for some reason it jumps the jack stands no one will get hurt nor damage occur to the truck or buildings. Have a man running the throttle in the cab and second man safely looking from ground level at everything spinning and see what is shaking.

-

Ready to do a fuel system

@trreed Could you do an article listing out all those parts, where you got them and how you installed your setup.

-

Bosch VP44 injection pump removal the fast way!

I see no reason for a two-year warranty. I've just cleared my 1-year warranty on the Midwest Injection pump that I bought from DAP and tapped the wire and still going. The sad part is, with 60k miles per year it will be worn out in 4 years.

-

Airdog filters only?

Spray the tube with WD-40 or silicone spray and then go for a drive in a dusty area. After a good amount of dusty roads and travel wipe the tube out with a clean white rag and see if any dirt comes out.

-

Apps going bad? No codes

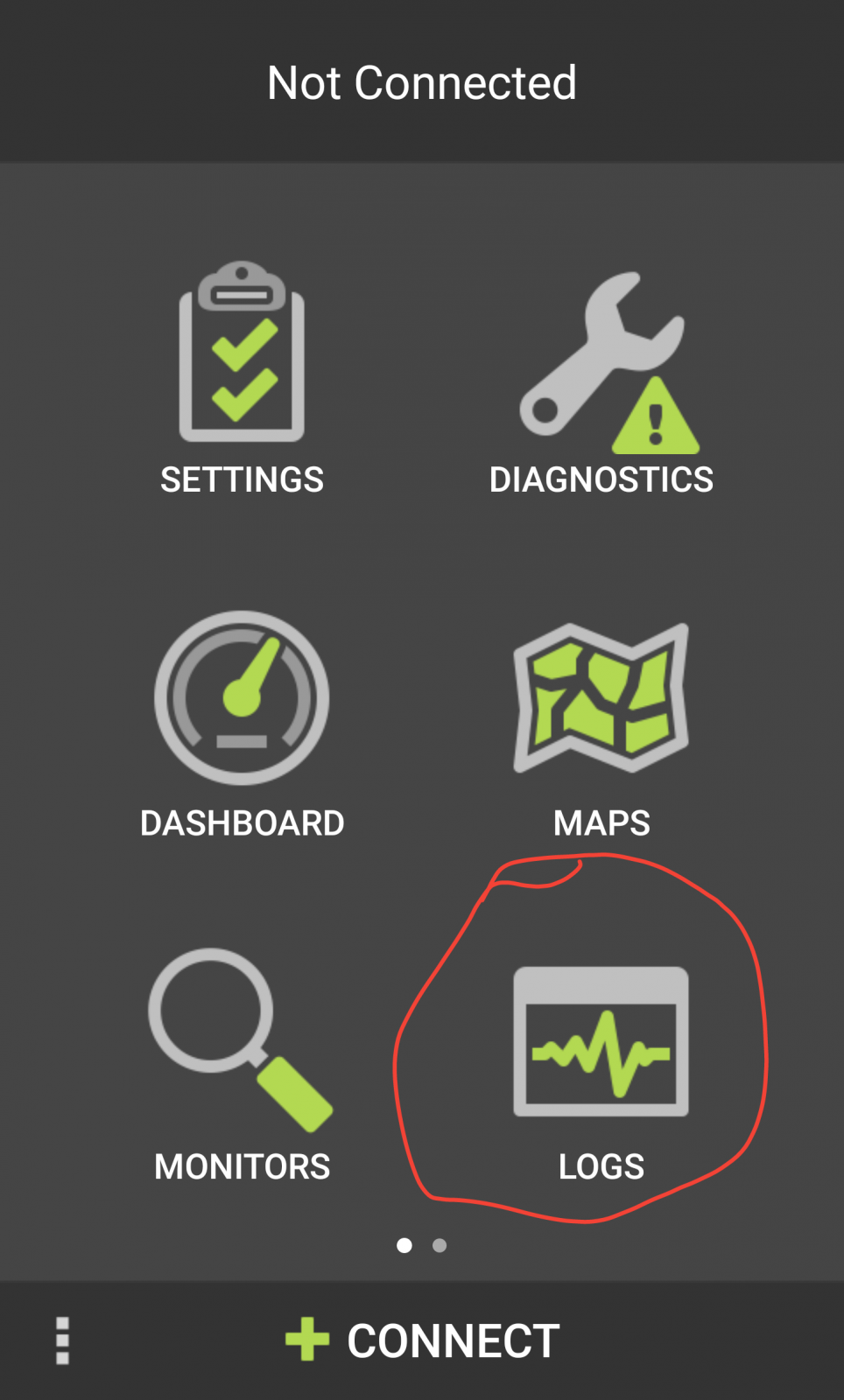

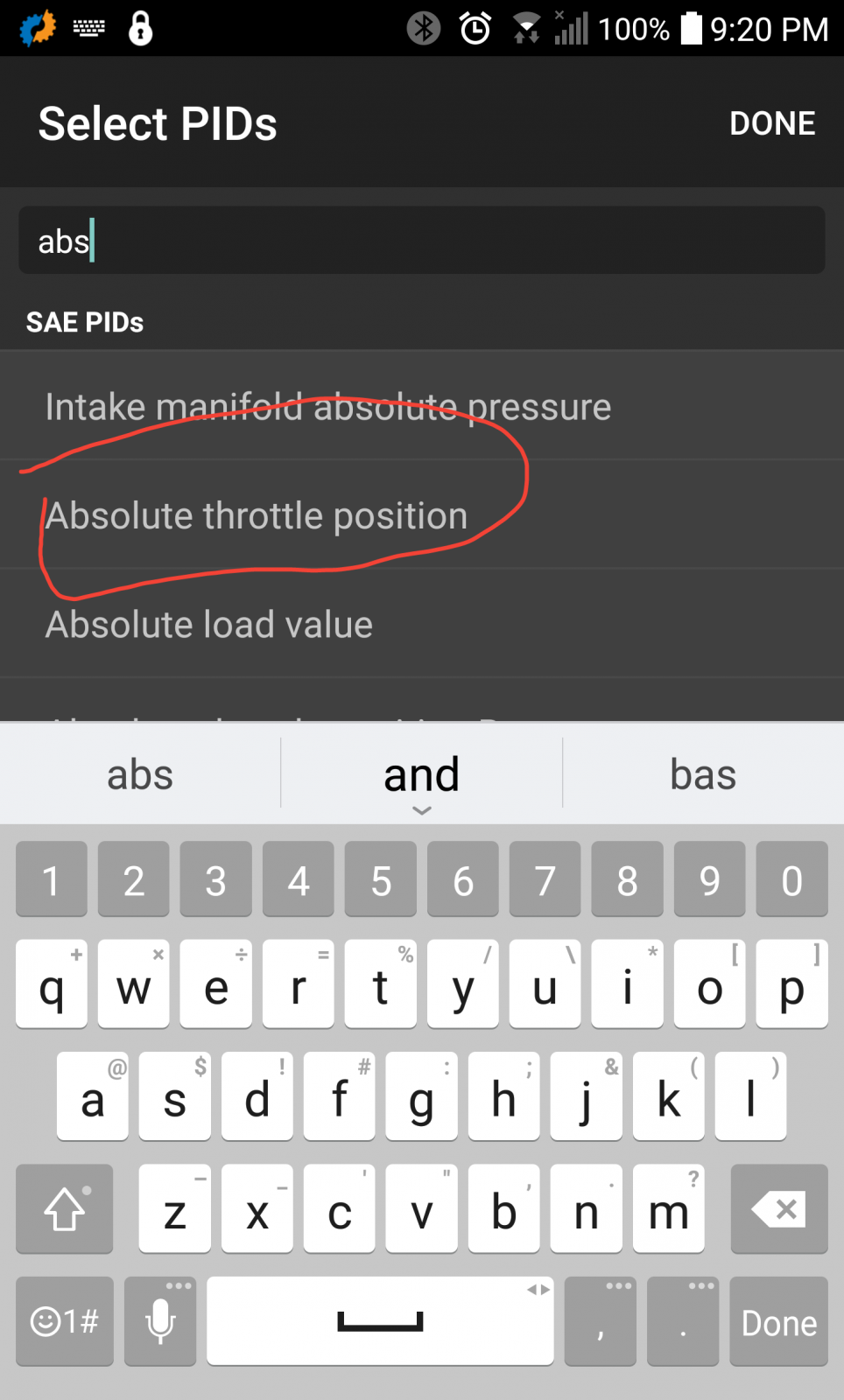

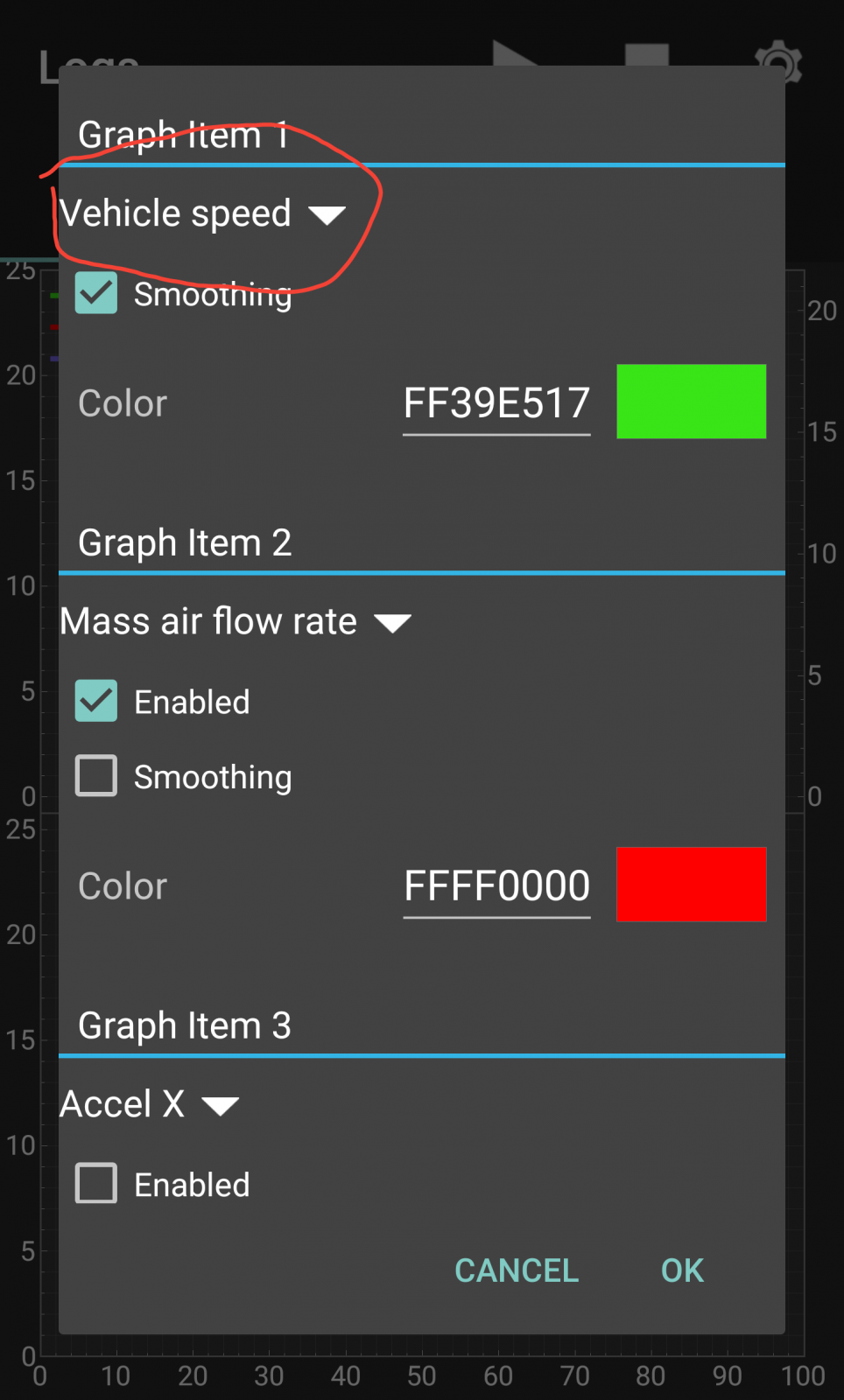

On the graph / logs section select one on the positions. Like I've selected the first one it will ask to select a PID. Do a search for Absolute throttle position.

-

Center Console/Armrest

@Macarena Man Could you shoot a picture of the power point and USB in the upper. I'm curious of the upper console. Does it say way Amp the USB is?

-

Apps going bad? No codes

You'll see the same thing numerically. You'll watch the TPS signal and slowly squeeze the throttle and watch the percentage of TPS from 0 to 100 percent. Watching for sudden changes or jump in the signal.

-

Apps going bad? No codes

Wrong values that is G force. It's attempting to measure the G force X, Y, or Z directions. You what Throttle Position Sensor (TPS).

-

No boost

Either the exhaust is plugged or the exhaust manifold is cracked enough there isn't enough flow to get the turbo turbine to build boost. Boost leaks in the air system somewhere. Damage to the turbo, the turbine is damaged from excessive heat or broke the turbo shaft.

-

Apps going bad? No codes

Plug in the OBDLink. Install the OBDLink App on your phone. Pair the bluetooth or hook up on the WiFi. Now monitor the TPS signal as you drive on your cellphone. Pretty simple. Hence why I've got the gooseneck in my truck. https://mopar1973man.com/garage/modification/279-mobile-phone-gooseneck/#

-

Bosch VP44 injection pump removal the fast way!

I'm pretty sure its Midwest Injection.

-

Heater exchange lines

Double checking... I still think your heater core link is displaced or install wrong. As you can see my line is back towards the block from the oil plug on the filter head.

-

Ready to do a fuel system

Personally... AirDog 150 - Small package easy to tuck nearly anywhere out of the damage path of the tires. I'm at 12 years of age and heading for 13 years. 150 model has better pressure stability over a 100 series which typically has a wider range of pressure fall. More volume the better the pressure stability. To install any fuel system is going to require dropping the tank and installing a 1/2" draw straw of some sort. Other than that you'll end up cavitating the pump and creating air bubbles.Best to have 1/2" line from the tank all the way to the VP44. Best pressure stability you can have. Keep in mind you will want to keep the stock filter can for extra filtration. Vulcan Performance sells the Big line kit for this. I ran into this problem as well with my AirDog I was running out of time and needed the truck. So I installed the pump and used the stock pickup basket this resulted in big drops of pressure during heavy throttle like pulling a grade. I'm not fond of the mechanical belt driven pumps. If you don't keep an electric primer pump you'll never get it started again unless you can spin the mechanical pump with a drill or something to prime the system again. This creates extra plumbing nightmare with check valves and tees to include the stock pump again. Lot of people like the belt driven because pressure rises with RPM. You have to remember this is strictly a pump. No air separation, no water separator, no extra filter. Like both AirDog and FASS you can get 3um filters. Basically stuck with stock filters. FASS I've installed a few of these and I'm not impressed. Extremely large pump and filter assembly nearly twice as big as the AirDog. This limits the install to basically where the manual suggest hanging it off the front bed bolt. This places the filters in the damage path and tends to get struck from all the road debris. The one I installed locally has way more issues with gelling fuel in the winter time than my truck. If seen a few local ranchers out here stuck in the backcountry because the filters got yanked off my logs, rocks and hitting the ground while being offroad. 13 years of hanging here... So old now the AirDog label fell off

-

Bosch VP44 injection pump removal the fast way!

Here you go gang... How to remove the VP44 the quick and easy way. Takes approximately 45 minutes for me to do this much. Remove the Mopar1973Man Crankcase vent (if applicable) Using a 10mm socket remove the air horn bolts and dipstick bolt. Using a 7/16 or 11mm loosen the top clamp of the boost boot. Move everything out of your way. Pack a shop rag in the intake to prevent stuff from falling in. Using a 13mm socket loosen the 3 bolts holding the APPS sensor and unplug and move. Now unplug the VP44 main connector and wire tap . This connector is a two step plug lock. Pull the release tab and wiggle the plug out then pull a bit more on the release and the plug should release fully. Now using a 10mm loosen the 3 bolts holding the 1,2,4 injection rail in place. Using a 3/4" wrench loosen 1,2,4 injection lines. Now remove 1,2,4 injection lines as a group. Using a 3/4" wrench remove the overflow valve banjo and remove your supply line (may differ from mine being a big line kit) Now remove the crankcase vent. Just unscrews normal right hand threads. Do not pry on the nipple. Now remove the pump shaft nut with a 1 1/16 inch socket. Using a 23mm socket roll the alternator towards the coolant bottle to bring the keyway on the pump gear to TDC position and then install your gear puller and pull the gear loose on the shaft. Now loosen the 3,5,6 lines but you do not have to remove. Now you want to loosen the 2 bolts on the rear bracket with a 13mm socket. Now remove the 4 nuts holding the pump to the gear case. Now careful kick the 3,5,6 lines out there nipples towards the block. Now lightly pry the pump away from the case and remove. Check for the key in the shaft make sure its present. This is what you should have after removal...

-

Fuel Article - Bosch VP44 injection pump removal the fast way!

Here you go gang... How to remove the VP44 the quick and easy way. Takes approximately 45 minutes for me to do this much. Remove the Mopar1973Man Crankcase vent (if applicable) Using a 10mm socket remove the air horn bolts and dipstick bolt. Using a 7/16 or 11mm loosen the top clamp of the boost boot. Move everything out of your way. Pack a shop rag in the intake to prevent stuff from falling in. Using a 13mm socket loosen the 3 bolts holding the APPS sensor and unplug and move. Now unplug the VP44 main connector and wire tap . This connector is a two step plug lock. Pull the release tab and wiggle the plug out then pull a bit more on the release and the plug should release fully. Now using a 10mm loosen the 3 bolts holding the 1,2,4 injection rail in place. Using a 3/4" wrench loosen 1,2,4 injection lines. Now remove 1,2,4 injection lines as a group. Using a 3/4" wrench remove the overflow valve banjo and remove your supply line (may differ from mine being a big line kit) Now remove the crankcase vent. Just unscrews normal right hand threads. Do not pry on the nipple. Now remove the pump shaft nut with a 1 1/16 inch socket. Using a 23mm socket roll the alternator towards the coolant bottle to bring the keyway on the pump gear to TDC position and then install your gear puller and pull the gear loose on the shaft. Now loosen the 3,5,6 lines but you do not have to remove. Now you want to loosen the 2 bolts on the rear bracket with a 13mm socket. Now remove the 4 nuts holding the pump to the gear case. Now careful kick the 3,5,6 lines out there nipples towards the block. Now lightly pry the pump away from the case and remove. Check for the key in the shaft make sure its present. This is what you should have after removal... View full Cummins article

-

Bosch VP44 injection pump removal the fast way!

I buy mine from DAP. DAP sells both Midwest Injection and Industrial Injection VP44 pumps. Vulcan Performance is another safe bet also sells Industrial Injection.

-

Apps going bad? No codes

AC noise can impact the throttle signal. Like on my truck with a manual it creates a surgy cruise control or using normal throttle it feels like you not holding your foot still even though the TPS signal says otherwise. This is because the AC noise muddy the tach signal from the engine and ECM starts changing fueling commands because of the noise in the tach signal.

-

Heater exchange lines

After going out and looking at my truck and comparing the picture to what I'm looking at that compressor housing has to HUGE. If the heater core line is bolted down in stock placement there isn't much you can do other than possibly dent the line where the compressor housing would hit.

-

Heater exchange lines

Heater core line. Looks like your manifold blanket is displacing the line.

-

Saying hi again

Software is constantly changing all the time. New features, new abilities, etc. Sometimes things get overlooked or software get old and starts failing. I've got no problem looking into issues if you can't get into the website.