Everything posted by Mopar1973Man

-

oil/fuel out of #1

Another question? How much oil are you losing if any? Are you consuming oil and having to add? I tend to agree with Bill it could be valve guides or the piston oil rings which could be weeping oil past. Like my own truck I get a nice blue cloud on startup now from the oil leaking past the valve seals. Not in a panic mode at all just live with it. As for showing up at the manifold mine doesn't slobber like that though... Is it possible the valve guide are worn and with the extra drive pressure from Twin Turbos that it wore out the valve seals early from pressure stress?

-

Sight Glass for Trans and T case

I can see putting a sight glass plug in for the axles or transmission. As for the transfer case it might be hard to get extra fluid in to see it in the sight glass. Little knowledge on sight glasses. Like old Honda motorcycles had them back in the day instead of a dip stick. Now the Honda motorcycle where horrid because about every year or two you had to pull the clutch cover and using a q-tip clean the glass so you could see the oil level. Yamaha got smart and used a wiper that you spun using a screwdriver to clean the glass. So consider the fact that crud will cloud the sight lass over time. Just like pulling the differential cover and everything has coating of the black that just wipes off.

-

Sight Glass for Trans and T case

Transfer case plugs are steel now.

-

Mechanical FP gauge

Too close to the VP44 is most likely what is wrong. Your at the strongest water hammer pulses from the VP44. So it would be best to move your tap point towards the stock filter or aftermarket pump.

-

Keeping Your Truck From Getting Stolen?

Not good enough. A third could use another relay like the horn to still start it. This why you need to make it harder to figure out. Missing relay is easy like pulling a fuse. What happens when everything is in place? Now the thief will more likely move on after he cleans out the cab like you ScanGauge.

-

Rear Driveshaft Universal Joints

I use a Harbor Freight ball joint press for doing u-joints. Just use a impact gun to drive the press. More or less a big C-clamp. Works good and quick to change out u-joints. I would suggest to get a small hone stone/brush and run it through the holes to clean them up a little bit. Take all the rust out and it will make installing much easier. http://www.harborfreight.com/ball-joint-service-kit-for-2wd-and-4wd-vehicles-60827.html

-

Big problem

So you need to pull the ECM plug and the Cam Sensor plug and ohm from end to end to see if there is any connection problems. This test should show 0 ohms but 0-5 ohm is acceptable. Then while its disconnected ohm from pug to ground looking for shorts to ground. So on this test everything should be infinite ohms or OPEN.

-

Ham radio operators

I remember the days of CB's... Now where I live it nearly impossible to transmit out of the valley floor. North end of Riggins, ID looking north as US95 travels the river.

-

Keeping Your Truck From Getting Stolen?

Fairly simple really. The fuel pump relay in the PDC is the power relay for the VP44. If you open the PDC up you can see the black ground lead for the relay. Just wire it into the cab on a SPST switch and mount the switch in a good hiding spot that isn't obvious. A single wire is really easy to tuck back in the main loom so there is no clue that that is the kill lead. The big trick is to mount the kill switch some where you can toggle without a passenger or other people looking can see you reach for. Like around your driver seat base maybe?

-

NV4500 fill plug thread and pitch

I'll verify temp measurements when I return home. Just using the hand method the case from top to bottom feels equally in temperature. So I'll verify oil temp with external means of measurement.

-

NV4500 fill plug thread and pitch

Second day of towing max temp I've seen so far is 170*F. Still averaging roughly 140 to 160*F. Still shifting very well. I've called Abe @ Weller TTruck asked him what max temp is for the 50 SAE trans fluid. He states that it failure point is 300*F.

-

NV4500 fill plug thread and pitch

Ok so I'm travelling with RV and will report after travelling for 1.5 hours at highway speeds I'm roughly holding 140-160*F running 4th or 5th gears. Now drop into town it will rise with 3rd fear but cools right back off once back at highway speeds. More to come...

-

NV5600 Fluid, Fast Coolers, Filter

I'm going to do the study work for the coolers now. As for my normal daily driving I'm hard pressed to get 140*F. That not even needing a cooler. Now I'll find out more during some RV and utility trailer towing. The only reason I don't way the fast coolers is because of the winter time temperatures. I don't what to have to keep swapping the coolers off and on just to get the fluid warmed up enough in the winter time. So consider you overall weather conditions and temperatures. Agreed. Now that I switch fluids and being what I'm using is cheaper that the original fluid I will be more prone to changing the fluid more often. Even with 261k miles on the truck I didn't have any debris even when the transmission did fail. So the idea of a filter isn't needed really. Now I'm experimenting with non-standard fluids I'm going to watch and see behavior of the transmission and temperatures. But so far it runs really really cool most times here in the mountain just empty driving. So far I've not seen a reason for the coolers as of yet.

-

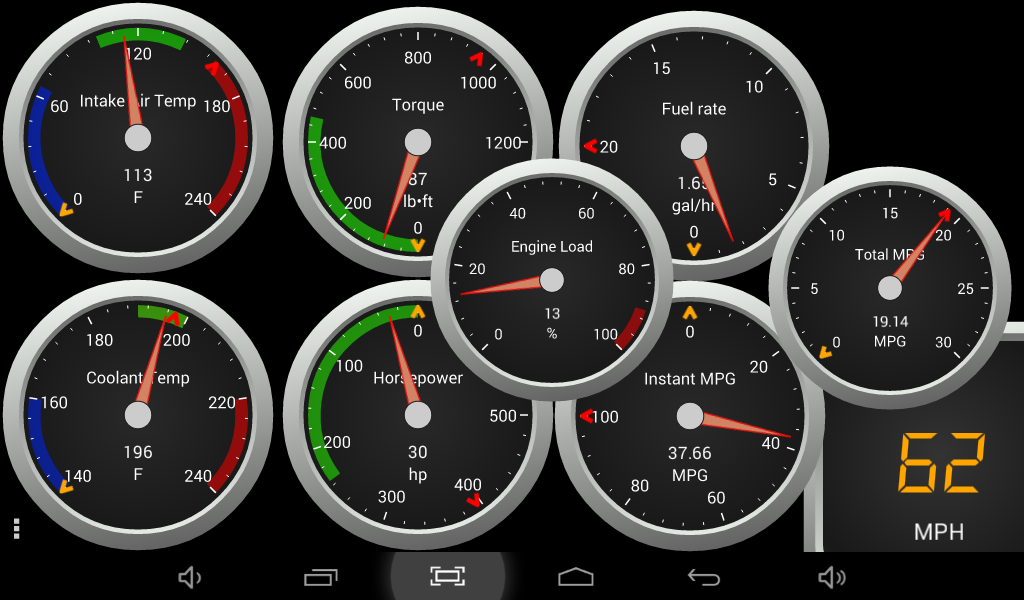

Ambient Temperature Depending Performance

First off don't bother pulling the IAT sensor. Just hook up a live data tool and watch the data. Nothing is ever gained from the old myth of cleaning the IAT sensor. I quit doing that years ago and just watch the sensor data. Colder the IAT the more advanced the timing will be come. Optimal IAT is when it lands in the green zone.

-

Running a bit warm

Just a plain ol' NAPA thermostat. I can reset the hi / lo markers on my OBDLink LX and see the limits of swing.

-

NV4500 fill plug thread and pitch

Had to make another trip into town today a bit warmer weather (~80*F). Still in all it take better than 10-12 miles to get the gauge to rise from the 100*F mark. By the time I get to town gear down for 25 MPH now the transmission is warming up to 130*F or so. Now leave town and head home it varies from 120-130*F most of the time.

-

Running a bit warm

Why not do the easy thing and leave the thermostat out till the block is completely filled right to the edge of the block. Now install the thermostat and finish filling. Never have an air issue then.

-

TFaoro how is this possible???

Now that looks correct... Weird how it was flipped.

-

TFaoro how is this possible???

But looking at the radiator its location and fan direction now dictates the rest. I've not figured out how to mirror an image that way. So he's standing on the driver side of the truck hood hinge is to his left, front of the truck is to the right. So how is the turbo on the driver side? Radiator cap on the wrong side too? Just flippin weird.

-

TFaoro how is this possible???

Take a look at this picture and figure out how everything is backwards. Turbos on the wrong side, etc. Look at it closely...

-

NV4500 fill plug thread and pitch

Out the firewall and more or less straight line to the passenger side of the transmission.

-

Running a bit warm

The older 12V tend to play that game more so because of the location of the temp sensors. 98.5 to 02 the temp sesnr is right at the thermostat so your seeing the hottest coolant right there. Back in the 12V they had the coolant sensor at the rear of the engine so by the time the coolant cycled and the coolant dropped enough to close the thermostat the coolant at the rear of the engine was colder. Hence the wide change of temp on a 12V vs our where it might rise and fall 10 degree roughly. Depends on the thermostat. Like mine pop open initial close to 200*F and then falls to 188*F then becomes stable at 191-193*F never changes unless towing.

-

NV4500 fill plug thread and pitch

Hmmm 1" maybe... Go the hardware store and grab a few different sizes of brass fittings.

-

Running a bit warm

This is why I always leave the thermostat out till I get the block right to the edge of the thermostat. That way all air is forced out and you drop in the thermostat and bolt it down and hook up your hose and top of with the last half gallon or so of coolant and your done.

-

NV4500 fill plug thread and pitch

Ok. I know this isn't much for load. I hitched up the BigTex 70TV trailer loaded it up with household trash and old tires I kept for spares. Maybe at the most 1,000 pound of cargo in the trailer. The trailer dry weight is 1,800 pounds. So not very much. I can say that traveling from home to Riggins, ID which is 1,000 feet elevation drop in 15 miles the trans temp never broke off of 100*F the whole way till I hit the city limits and dropped to 25 MPH now it barely made 105*F. So now the trailer is empty for the trip home. So cruise set at speed limit it took 15 miles to even get 125*F. Now worming around to park the trailer back in the yard and left the truck idling now it crawled up to 135*F when I parked it. Temperature wise I say this transmission and trans fluid is doing good. Like I seen more reaction from the boost and pyrometer as I worked the truck back up hill.