Everything posted by Dieselfuture

-

Airdog quality

I don't see why not, needle valve is just as simple though. And you can shut it of In case of leak or work that might need to be done.

-

Airdog quality

All that does is reduces pulse strength from pumps, and yes it won't be QUIK about being accurate but it will be accurate for daily driving. Pressure will not change just volume. And that volume in pulses from fuel pumps is what kills fuel gauges prematurely. That's why you only crack needle valve barely open, even on start up it will take a few seconds to rise to proper reading, but if you don't have needle valve it's almost instant. Think of it as a 12" water main in front of your house and you only have 3/4 or 1" line coming to your house. Let's say there is a fire few blocks away and fire department needs water, they hook up to a hydrant and fill their tanker up and a new guy doesn't know that when you shut off fire hydrants you go slower especially towards the end. If it hammers and most time it will it can easily brake water main pipe. If you had 12" main coming to your house and it hammered it would blow the end of it off unless you had a tank parked in front of it. So I guess my point is by reducing what's coming through you eliminating chances of blowing **** up.

-

Airdog quality

Ok just ordered titanium Fass150 from CPP, made sure to tell him i came from this site and Mike is the man. I talked with AD this morning and got poop for answer, basically I can buy another pump for few hundred bucks, just so it craps out again, I was nice and wanted to see if I could get o-rings and brushes maybe, "no we don't offer that", "not sure where you can get them ether". That's why I call you, You made this, shouldn't you be able to get me o-rings. WTF , I guess they won't make money this way. Jamie at CPP was pretty cool with me and hopefully in future there will be no problems with them, I'll make sure to send in warranty card too.

-

Airdog quality

without needle valve you'll prematurely damage your gauge or sending unit. Everybody on this site has a needle valve and maybe combined with snubber. only needs to be cracked open about 1/8 of turn.

-

Airdog quality

- Airdog quality

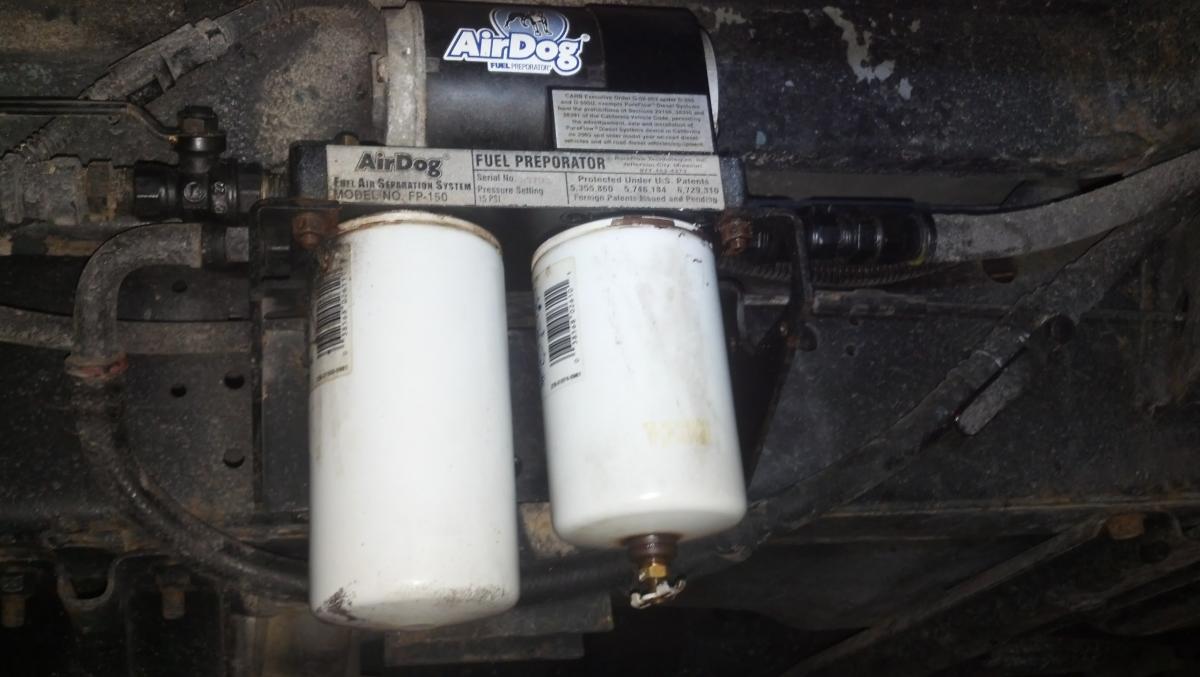

I didn't want to pinch lines every time I play with ball and spring or change fuel filter. so I added 3 ball valves, 2 on pump and one on line, if you look closely you'll see all 3. Plus my return and intake lines are both in fuel basket if I don'd shut off valves it would siphon fuel out ether line.- Airdog quality

You're right I don't have much choice anyway. I can't seem to find anything for it, I might need to call AD tomorrow. I've been Eyeballing http://www.fassride.com/detail/fuel-air-separation-systems/fass-titanium-series/fass-ti-dodge/dodge-98.5-04-150gph2.php and talking to my wife, if I get a green light then this is what I'm getting. And then I'll mess with AD. If I don't get a green light I might be stock driving my car for a while. Looks like Fass has as good of deal as any one of their dealers. Their saying 17,000 hours or 1,000,000 ml. Is what truckers get out of them.- Airdog quality

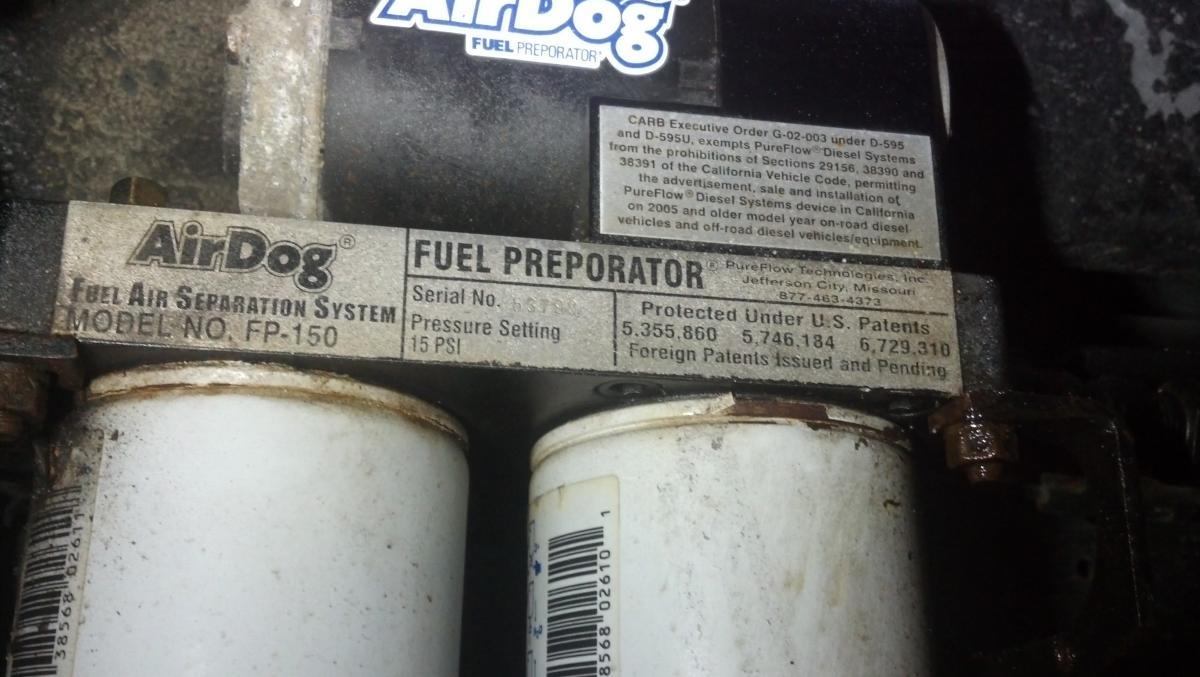

Sorry to bring this thread up but I think my AD150 is on the way out, maybe that's why it acts up sometimes in pressure spikes of 3 psi or so and gets a bit noisy at times. I noticed very small drip on the floor and decided to smell it sure enough it's diesel. here are few pictures. Looks to me like it's leaking somewhere from top by the motor maybe. At firs I thought it was my ball valves but it kind of looks like back of the pump. I seem to have an original AD150 and it was on the truck when I bought it 4 years ago. Does anyone know of replacement motor (pat# maybe) or should I just go with Fass?(most of you like more now) I just replaced all lines and got my fuel basket to work good, kind of want to reuse location and hoses. If I take pump off to look inside and try to fix it, do I need new gaskets? or it it o-rings that I might be able to reuse? I heard that most of the time it's oring inside that leaks in to motor, can I just clean inside and put new oring? I know it's a lot of questions but this sucks. I'm looking at all new front end parts too, On the good side my new cup holder should come in this week, so I can seat inside with no lift pump and enjoy my coffee. Thank you.- Console cup holder

Sounds good, when I had counsel cup holder I cut bottom out of one of them so my coffee cup sits in deeper and doesn't fly out on every corner. Just gotta remember not to put regular pop can in that hole. My bad I was talking about dash cup holder. Hey thanks for tis post, I just looked at it liked it and got one coming.- Fuel leaking from the fuel tank/sending unit on top of the tank

Yes ad150 has return to tank and mine is regulated with ball and spring, It used to be returned to filler neck but I had problem with 1/3 tank sucking air, so I got draw straw 5 and returned it to fuel basket. Some people don't seem to have problems and some do, but I'm not sure if they realize that with nidle valve mostly closed to keep sensors from getting hammered, it won't show up on gauge as easy, to test if you do have problem with 1/4-1/3 tank issues you need to open nidle valve up so it moves instantly. If you notice before and after pictures I already had 1/2 line there, it was the fitting to module that was restrictive. That fitting is original outlet for In tank pump and when you get draw straw 5 they tell you to use it as return. I was on the phone with Vulcan for few weeks and finally did it my way and it worked great, I called them back and said that they need to include another bung fitting with their kit in1/2" so people can return it to fuel basket and won't have these problems, the guy seem to understand what I was saying and say it's only happens with AD150-165 I was like yeah, and... So they know, not sure if they will do anything about it.- Fuel leaking from the fuel tank/sending unit on top of the tank

Actually that return line I was talking about is for Air Dog not for VP, VP and Injector return is still in original place with a clip in connector, which is even smaller about 5/16 OD and 1/4 id. But I see your point if a guy can up size that too then maybe it would help VP also.- Ball Joint Help

I hear you, but isn't spicer are the ones that came on our trucks? Or you're saying that replacements are still poorer quality? I got Sadler Power Train 5 miles from me they have all of it on hand I'll go check them out and ask a bunch of questions, see how fast they kick me out I actually know most of them there, been dealing with them for 15 years or so, hopefully they give me some answers.- Fuel leaking from the fuel tank/sending unit on top of the tank

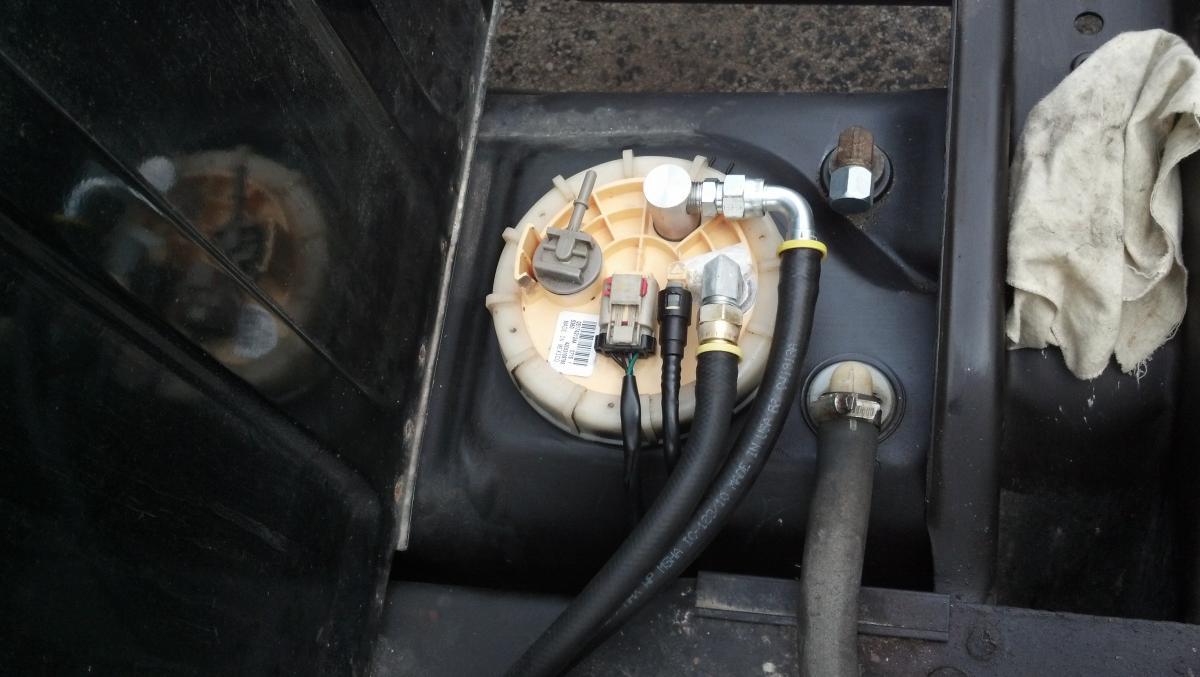

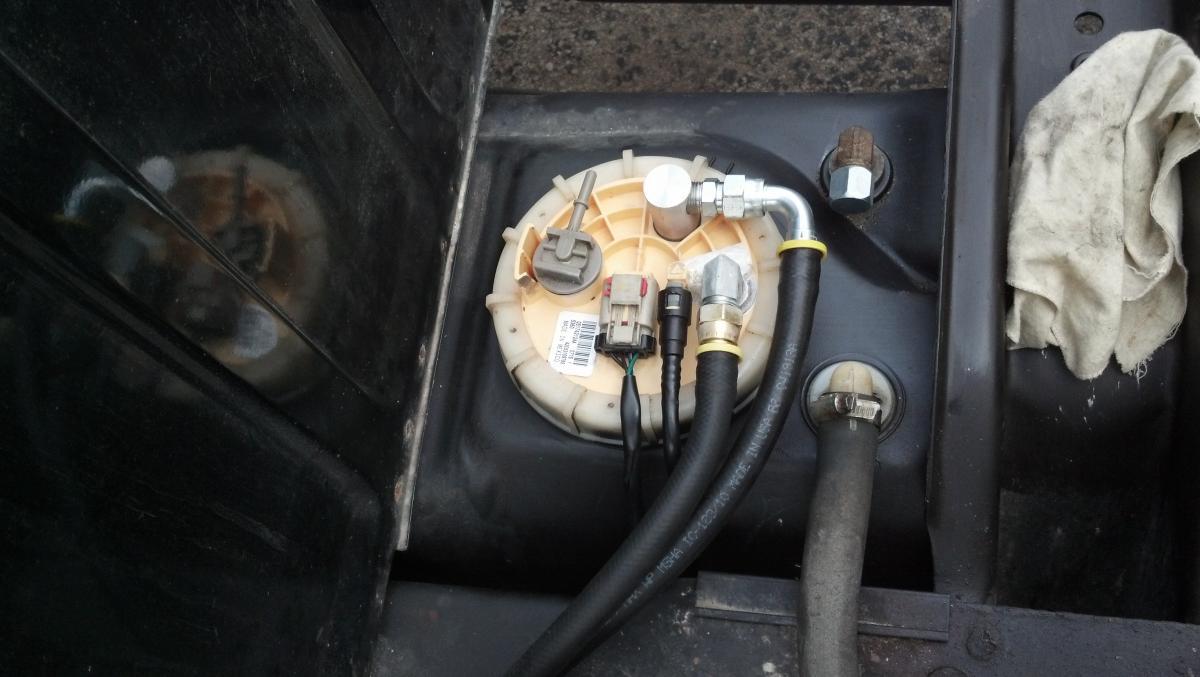

Thank you. When it's installed in tank I got about 1/2 gap to bottom, I did a little experiment with it and at first I had it just in the basket, and that made it foam, so I redid it and no more foaming when it's submerged in fuel. I did this test in 5 gallon bucket, tricky part is to cut it to right length, if you pull tank out and set it on floor instead of using straps depth changes a little. When I did mine I had 3/4 of fuel it tank.- Fuel leaking from the fuel tank/sending unit on top of the tank

I'm saying my total fluctuation is no more than 2 psi with 1/2 return where before, when I used quick connect that was 3/8 and inside more like 5/16 it would be as much as 4psi. That's what I drilled out and put jic fitting in. here is before and after. That white stuff is JB Weld rated for fuel, didn't need it but put it for support. It bonded pretty good. I got a piece of it in my glass jar with diesel in it along with a piece of hose that I used for lines, just seeing how long before it brakes down, so far solid as rock.- Fuel leaking from the fuel tank/sending unit on top of the tank

Here is my module that has draw straw 5 and my own return all in 1/2". I tried 3/8 in return before and pressure fluctuated to much, all in 1/2 1-2psi idle to full throttle.- Fuel leaking from the fuel tank/sending unit on top of the tank

I usually put two straps diagonal in side the bad and use engine hoist extended all the way out passed last hole, few inches in yet. But I do have a short box. I might go get a piece of square tubing that's a foot longer for this job later if I do it again. Obviously safety first- Ball Joint Help

I agree but also I think in this design it's not going to matter as much on greasing as much on material it's made out of. Because of the size of lowers and 100% of load on them! they should really make them out titanium, but I guess no one would be able to afford them. Maybe dynatrac is something like that and that's why they are so much more money.- Ball Joint Help

Do you have link to dynatrac that fits 00-02 I looked and seems it only goes to 00 and then says 99 and newer but how can it be past 02 if in 03 they changed size of them, I confused.- rebuilding the front end this weekend.. MOOG ok?

Seems that these days no one cares too much about going extra few feet to help another out, very few. Thanks for search and links, I might be doing this soon as my ball joints are on the way out. I think reason your shaft was wore out is maybe bad ball joints, axle would be misaligned and puts stress on where collar is. Just guessing.- Coil Springs

An update, now that I had them in for a while and got my bumper on which is about 200 lb at least, all 1/4 with 1/2 brackets. At first with factory bumper and 988's I gained almost an inch, now with new bumper and some time to settle in I'm at about 5/8 over stock. Glad I didn't go with any kind of spacers.- ..feels like I'm getting kicked in kisser

That makes perfect since to me, but if gas stations puts PS to treat their fuel, and if a guy dint know about it assuming they are using something else like A mix of #1 and #2 and adds 2cycle in then you're kind of screwed. And I'm not sure if it's just stations around here or a lot of them practice that.- Ball Joint Help

I'm getting a bit pist off, just finished bumper, springs, shock, rebuilt alternator, starter, a bunch of little stuff too. So after reading this thread I decided to check my ball joints and sure enough I can put pry bar under tire with it jacked up and move upper and lower up and down about 3/16 or so it's at least an 1/8 for sure. Did a quick search just to find out the only ones are out there are moog and spicer. I can get moog at parts store with lifetime warranty, and change them every so often or get spicer with no warranty and change them a bit less often. But if you keep changing moog in and out wouldn't that make the hole wear out faster. (no dirty thinking) if Mike reads this, Have you changed your ball joint yet at your 240k mark yet? If not, I'm going with spicers i think.- Odd one time bucking or surging issue

That's how truck gets a sole, you take care of it like Mike and ... Like I said wired things do happen. But yes I'm joking, usually if I don't have anything smart to say I say something funny. But does sound like fuel related, as Mike stated in many threads all it needs is compression and fuel at right time, assuming it's very well taking care of, I don't think it's compression- Odd one time bucking or surging issue

Maybe truck got nervous going to Canada, was it it's firs time? Weird things do happen.- 4x4 Issues

Could it be spider gears? How is oil look - Airdog quality