Everything posted by Dieselfuture

-

Well, the airdog, once again..

Do you really think a guy needs to change oil or fuel filters at least once a year like they recommend, or if I put 30k on my truck in 5 years what can possibly go wrong with filters other then get plugged with crap, and when you see pressure change that would be the time to replace the filters?

-

Thoughts on Edge EZ vs Superchips Flashpaq vs Other Econo Tuners

I've been trying to stay right at 55 and seems that I can't get over 17-18 but at 65 I seem to get right at 20. I got 3.55 also but my tires are slightly bigger. Also I got quad and on suggested level 5-7 I can't get over 17 but at level 1 which is max mpg (all timing) according to quad but they don't say how much timing ether, I get close to 20. Seems that at 55 I ether have to down shift a lot or egt and boost goes up and mpg goes down.

-

Well, the airdog, once again..

That's why I got FASS and rebuilt my old AD for backup.

-

Why is my right tire wearing on the outside?

When I do my front end I'll defenetely be getting a set of these.

-

will be busy soon, questions for the membership

Good time to practice on the old one drilling holes.

-

Airdog quality

Last I heard old water separators with plastic drain were bad design, and new ones had metal wing nut. But I would prefer the old one myself just wash it out with some gasoline and put it back on. Unless the outside rots away.

-

Airdog quality

No new bearings are a bit bigger in ID by about .0015-.002 so the bearing fell right on without being pressed, and I tried several brands of 608 they all did same thing. Guy at BDI Bearings took some measurements and said that 608 should work but obviously didn't, he said call manufacture and find out if they had them made special for them. So yea screw AD I'm not calling them ever again as last time they basically told me ... I did took the measurement of shaft but forgot to wright it down. All I remember is my gauge on caliper was about 1-2 thousands off.

-

Cracked Bezel

With that said, to make a perfect vehicle you need 5 or so different brands of them and then some redneck engineering, torch, welder, and you'll have something worth keeping.

-

Well, the airdog, once again..

I thought brushless has problem in colder weather, with thicker fuel it might just stop turning, almost like new cordless tools that are brushless they just stop when working to hard or battery is low. But I'm sure they had to think of that in their pumps. Maybe I'm wrong too.

-

Airdog quality

Not sure what to do next here, I assembled it back with old bearings. I changed 3 orings and put in a seal. Behind seal there is an oring also so with new seal I put new seal in first, then oring (not sure why it's there in first place), then I made a shim that fits snug between oring on top of the seal and before waive washer. This way seal is riding in new place on shaft, I also put grease inside the seal so it might help with life of it and aid in grooving shaft. This might be hard to picture, but if you tear it apart it will make since. Where I'm going with this, is I'm not sure how we'll come up with rebuilt parts if bearings are special. But everything else seemed to work. Maybe someone will find right bearings for this thing.

-

Lift pump failing signs

Other sings are: leaking fuel out of pump somewhere, if it's noisier than usual, pressure drops to low, but yes in winter, especially at 0 and below good chance is it's jelling. But like stated above make sure you have good power to it and relay is working, also make sure connection to ECM is good. I put dielectric grease on all of my plugs.

-

Airdog quality

here are bearings and seal for AD150 Bearing is same OD but ID seems a bit lose when I slid it on the shaft, maybe shaft gets bigger where bearing sits, I haven't pulled bearings off yet. Maybe part numbers don't completely match, AD is 608RS and the ones I got are 608 2RS. They are skate board bearings. Seal is identical to AD even says tiwan on it. Also here are filters that were on it, about 5k on them ff looks a bit dirty but separator looks new, but in between clits there were few small pieces of leafs and dirt. That means they had to go through the gear rotor !!! edit: bearings are too lose in ID by about .0015 they slide right on and don't have to be pressed on. I'll have to find out if rs and 2rs is what makes the difference. Seal worked. Edit: so I looked at other bearings and none of them fit tight on shaft, AD must have something made special for them. So I reused old bearings, they were still in good shape. Seal and o-rings worked. I have not tried it yet. Has anyone used FASS fuel separator FS2001 on AD150? Treads are same oring looks to be same, not sure why it wouldn't work.

-

Airdog quality

It does leave grove from finger nail for a while, in the name of since knife cuts right through it too. FASS was nice and send me two new balls and springs. so I now have one new ball in FASS and one spear. So far pressure is steady.

-

Airdog quality

Here are part#s from CAT for o-rings on AD150 Gear rotor cover 5K-0227. Base plate to Pump, bigger o-ring 8C-0563, smaller o-ring 8L-2746.

-

Airdog quality

I looked at bore of fass and it looks like machined aluminum, no rubber in side. and here is a picture of a ball that has two groves in it, one from being shipped to me and the other from running it for 2 days. And i confirm that the groove is from the seat and not the spring.

-

Fuel Gelling with 2-stroke oil

I did not drive my truck today, looked at my sample of fuel it was cloudy about -12 this morning. so they don't lie when they say it's only good for -10.

-

Airdog quality

I found some orings for between base plate and motor CAT #'s small 8L2746 $2 big 5K0227 4$ I believe they are both Viton. Also found seal at local BDI bearings 13$ and bearings 13$ each. Will post some pictures when I get them. That should be all unless other oring look bad and need changing. Honestly I think all orings could be reused.

-

Towing a 24 valve truck when broke down

Not sure how I got here, but one more thing to remember. Plug off exhaust with rag, so some how it doesn't draw air out of it and spins turbo, bushings/bearings might fail in turbo if it does spin when in tow. we did it with Duce and half's when using tow bar, or on flat bed.

-

Airdog quality

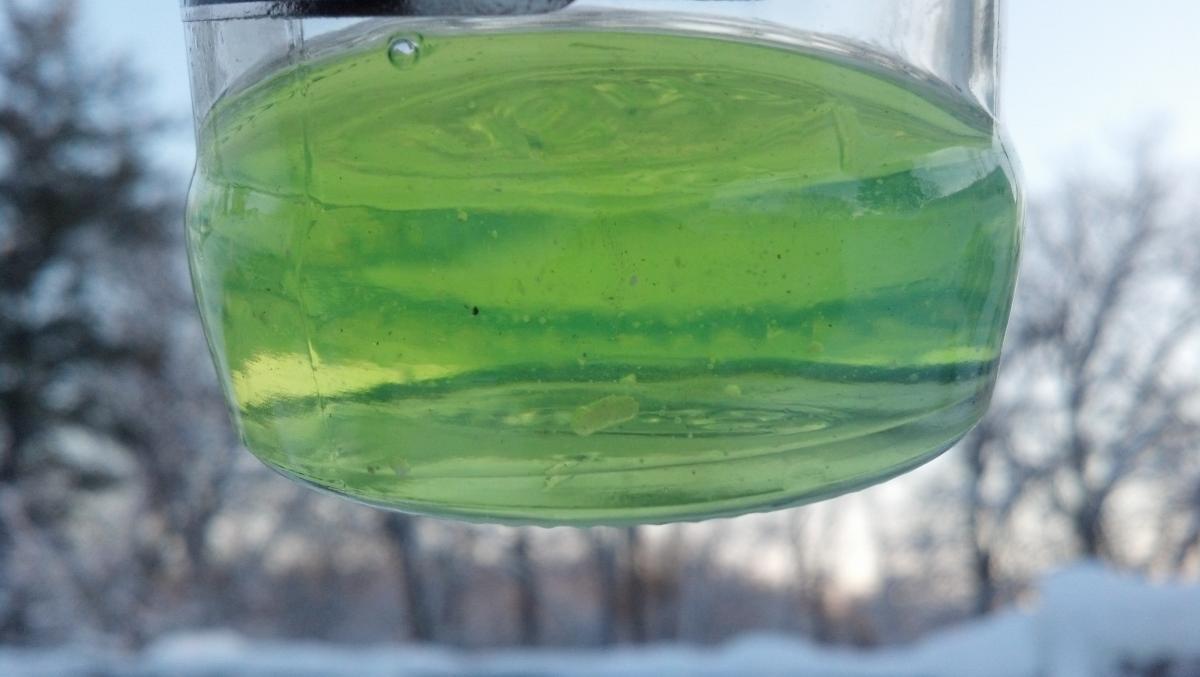

speaking of bio, this is 5-20% bio look at all ice particles in it. in regular diesel I never drained ice particles out of separator.

-

Lock up issues are back, fml

Hopefully you didn't get a$100 alternator at part store, and when you check vac rev up engine and see where it climes. At alternator.

-

Airdog quality

That's what I'm trying to figure out too, bio is vegi or some food oil, you would think that diesel would be more corrosive to rubber materials, maybe it's additives that's in it that make it eat regular diesel hoses and orings. On that ball if it was stell it would bit up aluminum housing that it's in, I thought why not make it like an intake valve on engine with harden seat and somewhat lose gide, and put same spring in front or even on back side, should last for years. IMO. I bet someone can even make it so it fits in the same hole, screw right in, might stick out a bit more. And on that seal they should use one that rubs on it self and not on the tiny shaft, that way seal wears out but shaft and housing don't.

-

Airdog quality

That ball is black in color, and it's viton, also found some orings today that are viton one was dark greenish color and the other was black. I used to think viton was brown but not so. Also stopped at CAT and looked at their chart, it said nitrile or viton for diesel fuel.

-

Airdog quality

You're probably right I was just brain storming, I would still check that ball out.

-

Airdog quality

I think you were close to jelling and viscosity of fuel was higher, so pump has gear rotor to pump fuel so it's kind of positive displacement. As fuel got thinker pump keeps pumping but can't get through lines fast enough so pressure goes up, that would be more likely especially if your return from AD to tank was reduced less than 1/2". Like if you're using fitting on module that is 3/8 for return. I had similar issues until I switched to 1/2" all around, I never had problem with return to filler neck but I had problem sucking air at 1/3 of tank if I slam brakes or get on it, so I switched to module in and out.

-

Airdog quality

About groove in ball, I believe it's from the spring but I could be wrong both surfaces are about same, spring and housing. I did talk more with fass today and they have oring kit for putting motor on other than that not sure. Fass was nice enough to me to day they send out new ball and spring after I told them I had issues with psi spikes and I moved ball and modified spring, and problem went away. They said its common problem and sometimes it gets bad enough where pressure will change as much as 10 psi. So yeah I would say modifying that spring somehow helps, and new surface on ball to seal against. I think they need to redesign it an do something like valve and seat like in a head. It will be metal against metal and if done right will last a long time.