Everything posted by trreed

-

Lift Pump

If it's Parker they have a facility in Alliance, NE. Only reason I know that is because I have a plant in Alliance and drive by Parker's place when I'm up there.

-

Lockup bog/timing torque/general q's

Curious. Mine will! WIth your 14mm studs I doubt you will do anything to be able to lift your head. With my 425's I'm sure I was close to breaking something here with as little fuel as it had..

-

Lockup bog/timing torque/general q's

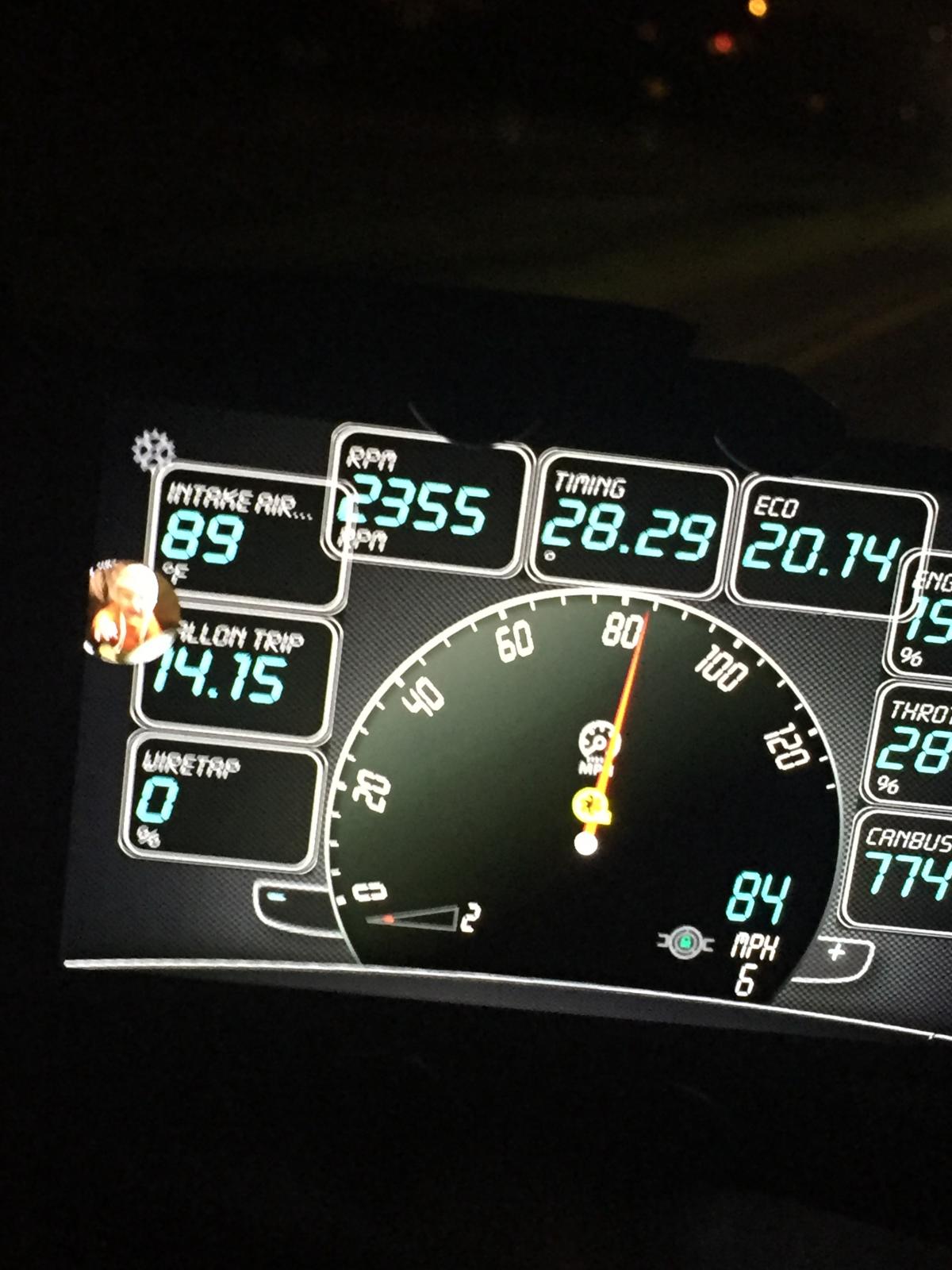

The 22/24/26/30/30 numbers are on my dyno/idiot/severely over fueled tune that starts at 101% and doesn't get used on the road except for when I find myself in Nebraska with nothing to do and no one is around. I was half trying to emulate a p-pump (with slightly dynamic timing), and half curious about what would happen. My mechanical pump will get sucked down to 11 psi at WOT. Stays at 24 while cruising.

-

Lockup bog/timing torque/general q's

Bigger orifice = bigger fuel droplets which usually means more timing is necessary to completely burn the fuel.

-

Lockup bog/timing torque/general q's

Well, thought it would be a good idea to do a burnout. It was not. This is a Dana 80 too, so your 70 would definitely blow up. As for the timing, I'm not sure the orifice size on the Mach6's, but with my 6x0.013's, my daily timing is 17 / 21 / 23.5 / 27 / 30. And then I have a tune where I'm not quite sure why I'm doing what I am, and that timing is 22 / 24 / 26 / 30 / 30

-

Lockup bog/timing torque/general q's

Yep, that'll be fun. My current carrier did not have any shims beneath the bearing caps, so hopefully the new ring gear doesn't need them either! Moral of the story is don't be a dumbass and show off!

-

Lockup bog/timing torque/general q's

I'm about $750 into parts for it. All Spicer components, except for the bearings, which are Timken. Doing the work myself, with a mechanic friend who I can pay in beer. Removal took an hour, cause I loosened the ring gear bolts while in the pumpkin still. Haven't touched it in a couple days, because I neglected to order the ring and pinion on the first go around and then it bit me in the ***. Going to take the carrier to a proper differential shop to get the carrier bearings off and back on, due to a lack of correct tools and knowledge on my part.

-

Lockup bog/timing torque/general q's

Yes, they are. Plus it's a limited slip so there's 6 of them. And clutches. And it chipped the ring gear and destroyed the tone ring.

-

Lockup bog/timing torque/general q's

-

Quadzilla Adrenaline Economy and MPG

A sh*tload of volatile fuel!

-

Heater exchange lines

Took bracket off and put in bending brake. Without the actuator, of course.

-

Heater exchange lines

- Heater exchange lines

Only thing that worries me about that solution is if the center section is too flat. The oil won't drain correctly if the drain line is too flat. I had an issue with my compounds where oil would push past the compressor wheel above 60ish psi- Heater exchange lines

Actuator will still function. What may happen is that the oil drain may not seal. I doubled my drain gaskets and used red rtv and it was fine. On my second sxe, I got smart and bent the wastegate bracket so there was clearance- Bosch VP44 injection pump removal the fast way!

Superglue the key in. Then no worries. Otherwise the key does readily fall out.- Ready to do a fuel system

I have a mechanical pump. Paid about $800 total for the pump, filter setup, regulator, hose, and fittings. Mine was NOT a kit. Pieced all that together. With the recent price increase of Fass pumps, I would lean towards spending the extra $100 on a mechanical setup. Reliability and pressure increase with rpm. I carry an extra belt, priming tool, and drill in my toolbox.- Heater exchange lines

The SXE turbos have a larger A/R ratio on the compressor housing. Part of the difference between the SXE and SX3 lines. When I had a single 62 SXE, the heater core line was very tight under the manifold..... but then again, I have a manual. I think the auto's hard lines are routed differently due to the block mounted heat exchanger. What may work for you is to modify the stock line to run above the manifold, bolt to a manifold mounting bolt, and use rubber to get to the heater core. This is the best I can find of what I'm describing. Look between the turbo and the valve cover, there's the rerouted heater core line- Choosing the right turbo

ORB stands for O-Ring Boss.- Choosing the right turbo

Some Borg turbos are 1/4” NPT fittings for the inlet, where the stock Holset fitting is M12x1.5 ORB- Everyone post a picture of your truck!

This particular picture happened in a town about an hour.5 from where I grew up in MN, and happened a couple years ago now. Looks like local law enforcement is on site there in that picture.- Everyone post a picture of your truck!

- 3rd or 4th Gen upgraded steering linkage? SAFETY RECALL (page two))

The ones that came with it! Sorry, I didn't stop to measure them.- Everyone post a picture of your truck!

Yeah I don't need mine either. I currently have three vehicles. Each serves a purpose. The pickup doesn't really tow these days, nor do I use the bed, but I choose to keep it around cause its a toy at this point. Nor could I give it up.- Choosing the right turbo

Yes. See how it runs. I'm not sure what AGP sets their gates to open at.- Choosing the right turbo

Loose nut is a lock nut. It should be tightened down against the sleeve. Purpose of the threads is to adjust the preload on the wastegate. The speed port does not need to be covered. - Heater exchange lines