Everything posted by CUMMINSDIESELPWR

-

12volt power outlet

i have one of these in the bmw, its about .1vdc lower than what is actually being put out. very handy https://www.ebay.com/itm/2-in-1-Dual-USB-2-0-1A-2-1A-Car-Charger-Voltage-Voltmeter-Motorcycle-Marine-Boat/253653127063?hash=item3b0ee78f97:m:mjkiN6Sju9e9GUIcSa3DIuw:rk:52:pf:0

-

My Love affair with BMW

i see we have another bimmer enthusiast! here is mine 04 330ci. its had some mods done since the picture

-

killer dowel pin question

when i rebuilt mine there was a hole where the dowel pin is but its too narrow for the pin to slip out. 01'

-

What makes 24 valves sound different from each other?

when i rebuilt mine, i can hear subtle differences in pulse and tones... i swear you just started mine up, sounds exactly the same hahaha

-

trreed's upgrade thread

my rebuild was with stock components, pistons (nothing fancy),rings and bearings are basically the only new parts.

-

16+ more years

my 01' is in great shape. only issues are the bed is starting to rust on the wheel arch, minimal "surface rust" on the frame and the cab just has a couple spots that need to be touched up. driver door already replaced but will get the pass door prepped to avoid rusting out. just need to change out the cab gasket around the doors and herculine stuff since carpet is out.

-

3rd brake light seal on cab rear

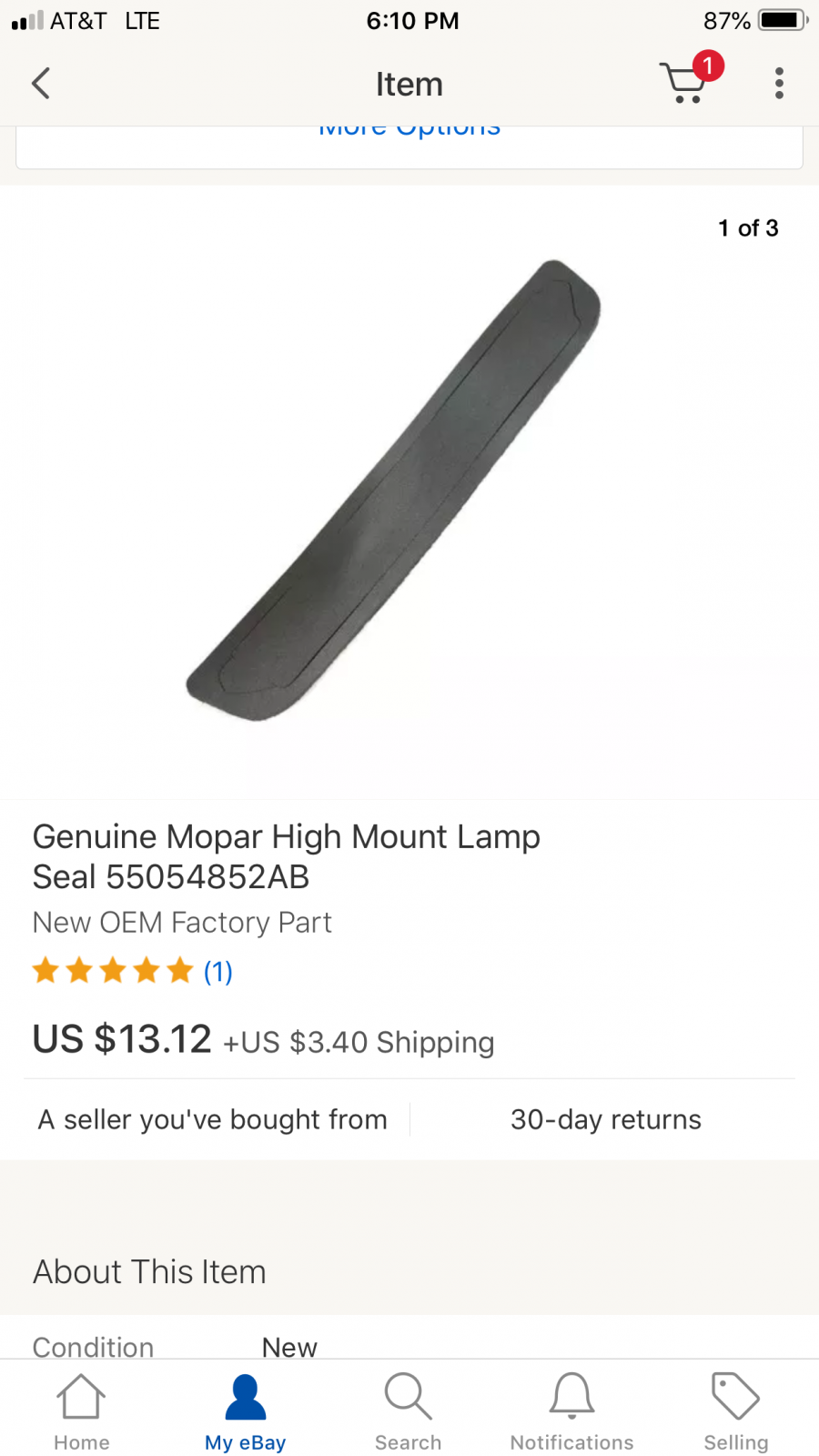

so the 3rd brake light seal finally gave up and shrunk to the point it was allowing water in. so time to replace got the neoprene gasket on ebay, good price. it fits perfect and as you can see its really thick (the old one was flat and dlush with the plastic housing)

-

trreed's upgrade thread

i get concerned at 1300 on a stock engine for a few seconds lol

-

241DHD T-case rebuild kit

http://www.quad4x4.com/catalog/category/dodgenp241dhd1998-2002parts

-

Stereo Head unit with Android screen

2 iphone 6+ and an iphone 5 ton of apps to use and have offline mapping as well. i can run torque app and motinor things if i want through a obd2 wifi adapter

-

Height Sensing Proportioning Valve TSB 05-04-98

which way is full open? currently i have mine ziptied level to the frame

-

Stereo Head unit with Android screen

you all should see my setup, ill get a pic today

-

Head gasket blown - Coolant leak

was working on a friends 3rd gen back in 2013 in colorado, leaning over the pass fender working on the bottom of the turbo trying to get a bolt to loosen, ended up breaking a rib i was pulling on the wrench so hard (and body weight-feet off the ground), my friend and his dad standing there heard a loud pop and i hit the floor gasping... there goes the rib. broke it 3/4 way through, really sucked

-

FYI... Recall

i did the factory mopar 3rd gen t upgrade back in 2010, ive had the thing rock crawling and zero issues, guess mine was before all this. spent about $450 for the whole thing but its nice

-

Head gasket blown - Coolant leak

your pistons are really damn clean mike!

-

Another failed AD

that might be a weep port if the seal to the motor fails. kinda like the weep port on a water pump.

-

Another failed AD

when i purchased mine back in 2011, the owner worked with me on troubleshooting the install (debris in return valve) i asked him how many miles he had his fuel boss for and told me he had the same pump and belt for over 150,000 or more miles. the pump is a straight cut gear pump. it has 3 moving parts (belt, two gears) as long as the belt is properly tensioned (1-1.5" play) the belt will last who knows how long and the gears wont wear the seals on the housing. i have 2 spare belts in the toolbox ive not needed since i purchased the pump. they are $7 each i think... i keep the oem lift pump installed but unwired to prime the system but probably gonna remove it. you can prime the fuel boss with a drill also, just remove belt and pulley and chuck the shaft into cordless drill and in a couple seconds its primed. it has my full confidence.

-

Another failed AD

cough (fuel boss) cough

-

5 and 6 speed owners

CUMMINSDIESELPWR replied to Marcus2000monster's topic in 2nd Generation Dodge Reliability / Performancewas in 6gear towing a dual axle overfilled uhaul trailer doing 70 from utah on 80 eb into wyoming and there is a huge valley with a very long downhill and a very long uphill. well i didnt realize that the truck was still trying to go uphill in 6th at 70 of course struggling and i realized i was slowing down and looked, egt were pegged, rpm was about 1600 in 6th full throttle (cruise) i caught it just as #6 started to melt in the bore. what happened was the lugging made metal on the mains and clogged the squirters from 6 moving forward... #6 was first to go all the mains were ruined, #6,#5 rod bearings gone $4500 later and its all rebuilt. Lesson learned. the only time im in 6th now is on flat road, no load and cruising above 65. otherwise im in 5th or below with a load.

-

5 and 6 speed owners

CUMMINSDIESELPWR replied to Marcus2000monster's topic in 2nd Generation Dodge Reliability / Performanceone thing you dont want to do is lug the engine load or no load. my old #6 piston can tell you why not to do it.

-

Power seat switches/functions

if you have motors that dont work...

-

Vp44 transistor replacement

keep us posted!

-

Another dead VP44

crack the board open and see if the transistor is toast, if it is send to me and ill replace it free, send back to you and see if it works again. im thinking if the solenoid gets worn and stuck, the draw on the transistor could also burn it out...

-

Head gasket blown - Coolant leak

i rebuilt the engine @ 207,000miles ive got about 15-20,000 since rebuild. all i did to the head were new stem seals. the shop did test to make sure valves seated good with a pressure test and the head had zero issues needing addressed so i just tossed it back on and bolted down with new cummins head bolts w stock torque (habit of not reusing old ones). they may have taken a thousand off the deck just to clean that up if that but the engine was in top shape (beside the #6 bore) had them work all the bores .20 over i barely had enough to get the engine rebuilt, adding the $1000 for headwork wasnt feasable. im basically stock though so not worried

-

Head gasket blown - Coolant leak

when i rebuilt mine i didnt do any head/valve work, just had the shop check for flatness and was done. slapped back on and works fine