Everything posted by Mopar1973Man

-

Airdog and fuel pressure

D'Oh! Feed cable voltage drop testing...

-

2 cycle oil

110K miles and still rolling with 2 cycle oil mixed at 128:1 ratio... No problems to report.

-

Biodiesel

Yeah I know its a extreme side of the biodiesel story I know those kind of failure are rare for station bought biodiesel but as for homebrew diesel its still very possible to opps on.. So I typical post up the thread to let people know it not something to take lightly about. If you going to make your own biodiesel make sure to get a game plan and stick to it don't cut corners on your production. Maybe I mis-understood you orignal post as for producing your own Biodiesel. :shrug:But as for purchasing B2 or B5 thats fine and will have little to no problems with it.

-

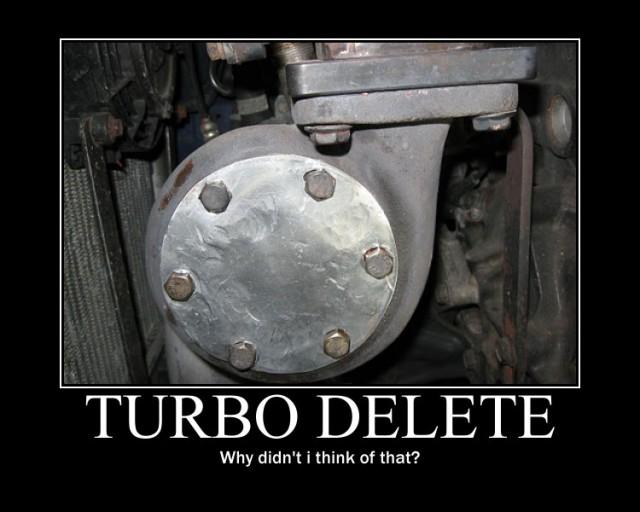

Turbo delete

ISX does have a valid point. But You know CF for the lazyness they have over there... (Use The search function) But I'm having a nice chuckle from the turbo delete... Personally I stay over my side of the fence and look for MPG and Milestones... I typically don't get into flaming threads...

-

Airdog and fuel pressure

Ok... Now then start looking at doing a voltage drop test...

-

Turbo delete

I'm still laughing my arse off about a kid over at CF.com that is asking to put a smoke switch on his Cummins at the same time he's going to install a P-pump conversion... http://www.cumminsforum.com/forum/98-5-02-performance-parts-discussion/460623-smoke-switch-24v.html Someone replied with...

-

NEW Guy help please

-

1800 miles 12.5 mpg towing

Simple then get a ScanGauge II then you can see the MPG's without filling up all the time... Trust me at $4.229 a gallon for diesel locally I don't even want to think of the $150 bill to fill from empty... http-~~-//www.youtube.com/watch?v=SRQdoPs_tLo

-

Airdog and fuel pressure

ECM... Still hooked to the ECM for trigger on and off but the pump power is in the PDC box not the batteries... True the volt drop with pull down all accessiores. You might have the batteries load tested just to verify they are good. Maybe why I don't see like many others is because my electrical system and batteries have always been kept up... Here is my article on my fresh batteries...

-

Programers ???

Hitch and load at 16,080# I run wide open in the Edge Comp (5x5) don't look back just keep rollin' !!!

-

NEW Guy help please

If its a brass or steel fitting you can solder wire right to the fitting but make sure to zip tie the wire too the wire will eventually break free because the solder makes it brittle.

-

Smarty Programmer

Or the other long shot and take to the dealer with the high idle TSB...

-

Biodiesel

I'm a clever man... I got him to ask the question... Here is a few article... http://forum.mopar1973man.com/threads/2158-Biofuels-emit-400-percent-more-CO2-than-regular-fuels?highlight=biodiesel http://forum.mopar1973man.com/threads/93-Bio-Diesel-and-the-effects?highlight=biodiesel

-

A thought...

Correct... You would have ot find away to gain control of the valve train and hold the exhaust valve open during compression stroke.

-

Biodiesel

Your fine where you at... :thumbup2:As for biodiesel I'm a bit leary of it...

-

chat room

Ok... The chat room is installed and rather raw at the moment I think you guys can't sneak into it if you wish...Under the Mopar Forum Tab go to Community Drop down and select Flashchat...

-

chat room

:lmao:Very Funny Dave... No what it is that most of the flashchat programs where design for the older vBulletin 3.8.x software and I'm now up to 4.1.8 and going forward. Well the guy that produced the software seems to dropped off the planet and hasn't really updated the software since 2010. :banghead:So I'm digging for answer why I'm getting error during the install and why the chat program isn't hooking to vB4 software...

-

chat room

Well I'm running into snags... I trying to figure out the errors in the software mis-behaving... :banghead:

-

Airdog and fuel pressure

I'm tied to the power lead in the PDC box for my AirDog and the ground wire to the body... Nothing tied directly to the battery.

-

Parker access valve?

Vulcan Performance sells them too... Just without the valve and with a cover cap.

-

Airdog and fuel pressure

My pressure never changes really... Cold start the fuel pressure will be a bit lower but no change from grid heaters. Once it warms up it back to 19 PSI at idle and 17 psi WOT...

-

Possible VP

Here you go... P0216 Fuel Injection Pump Timing Failure P0500 No Vehicle Speed Sensor Signal P0380 Intake Air Heater Relay #1 Control Circuit

-

Possible VP

I would say more a Vp44 issues that APPS. Being there is already a VP44 code there is damage there for sure. As for the APPS sensor its possible but not enough to warrant replace yet being the VP44 is already screaming...

-

Possibly an electrical issue

Glad you found a fix...

-

NEW Guy help please

The only thing that sucks is there is no ground to that fitting so electric gauges don't work this is why I don't suggest the grease gun hose either because there is no ground reference. So if you use the fitting like cumminapart did but put it back at the stock filter housing or at the lift pump (AirDog 100/150) then your good. Just don't want the fuel pressure sender anywhere near the VP44 or damage to the sender will result sooner...