Everything posted by Mopar1973Man

-

fuel leaks at cylinder head

Ahh... I had the same issues but got crazier... I got out the 1,200 grit and a pencil and tuned the connector tube to fit the lines. I had 3 line that when in bad shape and cleaned them up really well and carefully. A small scratch or pit in the connector tube or the high pressure line could cause what you taking about. I got to admit it takes a lot of patience with the 1,200 grit but you turn out a very smooth and tight seal fitting. Like I said take your time and do it right.As for the cause of the funk is from wahing the engine and letting it sit to air dry. If you wash the engine and drive it dry you less likely to have that issue. I had to learn this myself...

-

fuel pressure too high

There was a guy that converted over to 12V cam and 12V lift pump and had 35-38 PSI going to the VP44. Needless to say he got ran off another forum for it. So as for knowing if it work or not I say it was running but as for long term damage I'll never know...Still I will not suggest crossing the 20 PSI mark there is no need for it...

-

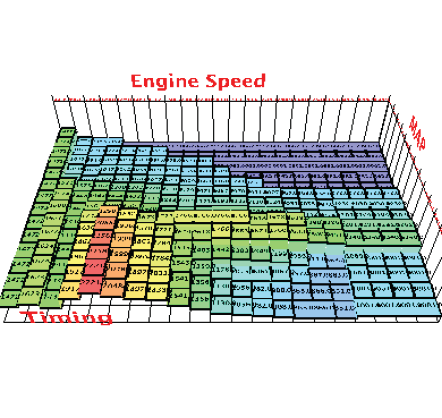

Dead Truck

Yes you injectors have to be re-popped because of the lower pressure of the p-pump. As for the p-pump where the gear is place on the pump shaft that is the timing its get all the way across the RPM span... As you see the pump shaft is nothing more that a camshaft. Now on the VE pump and VP44 pump they have a adjustable cam ring that move forward and backward in time to allow for timing changes. The VP44 is fully electronically controlled from ECM sensors and feedback and the old 12V had a single sensor for controlling the advancement cam and the rest was mechanical. But the P-pump its static fixed. So if the initial timing is 13* BTDC thats the timing for all the RPM span... VP44... Vp44 has a very dynamic timing table that is adjusted through engine coolant temp, Intake temp, boost pressure, throttle, and engine load. Yes I know the VP44 stock table is rather weak for MPG's why most people plug in a chip of some sort and get instant timing upgrade.

-

fuel leaks at cylinder head

Don't need to actually remove the injectors but you'll need to wiggle the parts a bit so when you tighten again it will actually seal up. Dave from over at RamForum.com was the once that got me on the phone with the injecotr company and I listen to there conversation about leaking fuel lines. As I posted above was his suggestion and it seen to fix his problem as far as I know.

-

ECM Issue?

If it was me I would back out of the Quadzilla addons for testing purposes and see if the problems go away...

-

fuel leaks at cylinder head

Ok... When you installed the injectors did you tighten the connector tube first or the injector cap first? I found out that you should tighten the connector tube before the injector cap this always the injector to move into alignment to help seal the lines. So if it was me I would consider doing that it might help...

-

Omgili.com

Oh you have no idea of the search I've back tracked and found that Mopar1973Man is on the first page or at the top of the list... Even worse to find 2-3 link in a row on the first page of google... I've been studying the Google webmaster page closely to get the most out of the site and its working we are getting much more impressions that we ever have. Just in the last day we went from 250,000 impressions to 300,000 and gaining 40-50%...More we post the better the odds... But there is another trick I found that works excellent. The fact we all use acronyms for most of the post to save on typing. But when we do searches for anything we all was spell it out. So if we spell out the parts completely like instead of "VP44" you type in "Bosch VP44 injection pump" so now if some searches for a Injection pump, VP44 pump, Bosch Pump, Bosch VP44, etc... There all now valid searches and the more times the words are use the better chances of getting to the top of the list even above big sites! We done it more than once already! So enjoy the new search engine... And thank you for the help in making it grow!

-

not a good way to end the day

You setup should be like... Return line is going to remain a banjo bolt fitting... But the supply line will up grade to rubber...

-

Omgili.com

Here is a weird find... I was digging around the site logs and looking at different spider that are crawling the site and found this strange little forum search engine that might prove to be useful... Take a peek and give it a test run... www.omgili.com

-

Hello from Houston, new member

Kind of a seal unit thing... Problem is getting the glass out without breaking it... Here is a thread I started a while back looking for mirriors... http://forum.mopar1973man.com/threads/4767-WTB-Fold-Out-Towing-Mirrors-(Heated-amp-Electric-Adjustable)

-

ECM Issue?

Not knowing you year of truck but I'm going to drop a link to the wire map... http://articles.mopar1973man.com/index.php?option=com_content&view=article&id=87:dodge-ram-turbo-cummins-24-valve-engine-wiring&catid=26&Itemid=107 PCM (Powertrain Control Module) is what controls the A/C, Voltage regulator, transmission,etc... ECM (Engine Control module) is what controls the engine and VP44. As for using someone elses ECM or PCM remember they are VIN locked so don't expect it to work properly either. It is a protection system added to the device to keep unauthorized software/hardware from being use accidentially causing engine or truck damage. Sounds like a wiring problem...

-

steering wheel nut size

I got smart early on and got a steering wheel cover for my truck. So my steering wheel is like factory fresh yet... I think the fact the 96 was already wore out on the top of the wheel got me thinking about protecting the wheel early on.

-

ECM Issue?

Dripley is right...

-

My first gasser

How about adding some pictures of this beast to the thread... I'm curious of what its... Maybe its time to update your vehicle articles...

-

intermittent miss on 3 different trucks

Like myself I've got a stock fuel heater with my AirDog 150 as well hooked up and even then it takes several miles like 50-60 miles to warm up that full tank of fuel from near 0*F temps. You got to remember the fuel leaving the engine and VP44 might be warm but by the time it flows back to the fuel tank through the steel return line it will be much cooler.But fuel temperature problem would be visable on the fuel pressure gauge with a serious drop lower than typical like me I lose about 3 PSI from typical with temps as low as 0*F. I don't use any fuel anti-gel either.I'm thinking its a fuel system related problem for sure but what I'm not exactly sure yet...

-

not a good way to end the day

As far as the return line I would still call Eric at Vulcan Performance and talk to him about the issue and he might just come up with a custom kit to meet your requirements of the rotten fuel lines... Eric a good guy to know when it comes to plumbing on the Dodge Cummins trucks!

-

Dead Truck

P7100 is better for power and longevity... But it will cost you dearly to convert to it. There is a minor down side of the static timing in other words timing is fixed compared to VP44 with dynamic timing that varies with weather and road conditions. (I know I'll hear from ISX on this )You also got to remember all the little thing too like throttle linkage is not part of the kit. Also your injectors have to be re-popped to match the pressures of a P7100 which is lower if I'm not mistaken. Change the cam or pull rthe cam to change the gear case plus consider installing the mechanic lift pump or going with a AirDog for P7100. Lots and lots of things to spend money on and so much work has to go into conversion...I still say VP44 is still worth it.

-

injectors

Measure the pintles and the bore and be sure they are fitting properly... Like mine where gummed up with coked fuel and the pintle needles where about 1/2 thousandth tight. After cleaning then they fit good and smooth again.Might also look into your fuel filter and the media your using I aim for a 2-3 micron filter. Using either a Fleetguard or a Donaldson filter.

-

not a good way to end the day

Just be easier to convert over to a Big Line Kit and be done with it... Vulcan Performance sells the kits and they are rather good price for excellent quality! http://www.vulcanperformance.com/Draw-Straw-II-1-2-in-draw-tube-and-1-2-in-pushlo-p/prs.htm

-

steering wheel nut size

Dang good deal...

-

injectors

Dirt and debris... Same thing that was wrong with my RV275 I got from CajFlynn they seen over 400K miles of roads. But they just didn't work to good for me. I took them apart and clean them up and everything works good now... Injector Cleaning

-

Dead Truck

P-pump conversion will cost you upwards of $3,500 to $4,000 said and done...I second the motion for the stock VP44... :smart:What you spend in conversion I can have enough VP44's to make a million miles nearly...

-

Low end power

ISX did the tesing a while back and adjusted his valves for max gap and it still ran just fine just doggy. So I'm going to agree with him it either injectors or timing...

-

1800 miles 12.5 mpg towing

A way to find out is measure the amount of torque required to turn the axle with and without the front shaft in.

-

1800 miles 12.5 mpg towing

Less rotational mass... :smart:On our truck the front axles are soid so the axles and the driveshaft spin all the time so if you pull the driveshaft off then you reduced the rotational mass on the front axle (in theory).