Everything posted by Mopar1973Man

-

MPG fooler - Design phase

Actually better at Edge Comp on 5x5... http-~~-//www.youtube.com/watch?v=xDvurlwOYsU

-

MPG fooler - Design phase

Smarty or a trip to the dealer would do it... As for a design template for the MPG fooler Yes... But remember you need the IAT plugs and the 2K resistor in place of the other parts shown. Yes. Prowelder is the site's manufacture of the high idle kits... Currently in debug phase for the MPG/High ilde kits.. Well the high idle designs are here... http://mopar.mopar1973man.com/cummins/2ndgen24v/high-idle/high-idle.htm The MPG fooler design are here in the thread... I'm already feeling the pinch here at $4.319 and going up yet...

-

Injector Virgin

Download both files?

-

2005 I Think

Well the limp mode should have a error code with it. I would start there and see what is going wrong...

-

MPG fooler - Design phase

Basically build a ECT fooler but using IAT plugs and then replace the resistor with the 2K ohm. Really simple.

-

Apps acting funny!!!

Just a nice molded plastic part to hold the terminals in place. That all I know of...

-

Apps acting funny!!!

Sounds good in my book... as long as the field wires are hooked up and the positive cable runs back to the fuse box its all good...

-

Injector Virgin

Here try this one... http://forum.mopar1973man.com/downloads.php?do=file&id=182

-

AirDog Filters Cross over?

As far as my AD 150 there is no crossover... Either fleetgaurd or AirDog filter that's it...

-

Engine Rewiring

D'Oh! I could of told you that one about the grounds... Dang... So close but so far away... The sensor base there grounds on PCM grounds not body gorund. Same with ECM on the 24V truck they base off the ECM ground not body ground. This is why its so critical for grounds to the PCM/ECM be in good condition because the internal ground that the ECM/PCM create are based off them.

-

Failed emissions :(

Canada... Well thing is there is a lot you can do to increase the power of that truck but remember your going to have to learn how to do it so when its time to smog it again you can reset everything back again. But before you get into making power mods I would get a set of gauges first. Then if you want two knowledgable people talk to MnTom and ISX they are both 12V owners that can point oyu in the rigt direction...

-

Two issues with truck 6.7

Well check for the error codes and report back the codes... Rattle noise could be the CP3 pump. There is a long article somewhere on the internat about the CP3 gear index might land in a spot where the pump comes over the pressure point flings against the cam gear causing the rattle noise. I heard if you just re-index the gear in a new position it will resolve the issue. But if Wild & Free shows up he'll be able to verify this information a bit better...

-

coolant smell

Well its not to bad to do a heater core here is a write up of it... http://mopar.mopar1973man.com/cummins/2ndgen24v/hvac/evaporator/evaporator.htm

-

65v70mph worth it

First you got to have traffic to imped there none here in Idaho... Seriously drive with common sense... Don't be a jerk about getting out of the way. If there is a pasing lane stay to the right and allow traffic to pass. If you have to slow down to allow the traffic to pass you. Fuel distance for 35 Gallons 27 MPG = 945 Miles 26 MPG = 910 Miles 25 MPG = 875 Miles 24 MPG = 840 Miles 23 MPG = 805 Miles 22 MPG = 770 Miles 21 MPG = 735 Miles 20 MPG = 700 Miles 19 MPG = 665 Miles 18 MPG = 630 Miles 17 MPG = 595 Miles 16 MPG = 560 Miles 15 MPG = 525 Miles 14 MPG = 490 Miles 13 MPG = 455 Miles 12 MPG = 420 Miles 11 MPG = 385 Miles 10 MPG = 350 Miles 9 MPG = 315 Miles Dark green is my typical economy driving. Light green is following speed limit. Red is trailer towing (7K to 8K).

-

codes....Help

Well I would try reseting the codes with another tool just to be sure and then take for a short drive and check the codes again. If the codes remain gone (Good your done). If they return then you got a broken wire or corroded connection somewhere. More on the CCD Network. http://mopar.mopar1973man.com/cummins/general/ccd/ccd.htm

-

codes....Help

Well the P1694 states there is no communication between the ECM and PCM and that the CCD network is possibly damaged.

-

raptor 150 install

Ok... 2 issues [*]As for mounting outside the frame rail be aware of the debris path from the front tires. Is stones and road debris going to hit the pump and filters? If so you might build a shield to protect them. [*]As for tapping the VP44 I would suggest you use a stealth plate to do it. Then you have a weatherproof connection, no damaged wires, and most VP44 vendor won't even know the wire been tapped.

-

New Guy

New post is prefered then the people will see it...

-

New Guy

Welcome to the group... Well you came to the right place... We we will do our best to try and help you out and solve your problem...

-

Apps acting funny!!!

Sounds like you might be calling Timbo... http://mopar.mopar1973man.com/cummins/2ndgen24v/apps/timbo-apps.htm

-

Check This Out

Good one guys...

-

80,000 Miles......No Full Oil Change

1-2 hours most...

-

80,000 Miles......No Full Oil Change

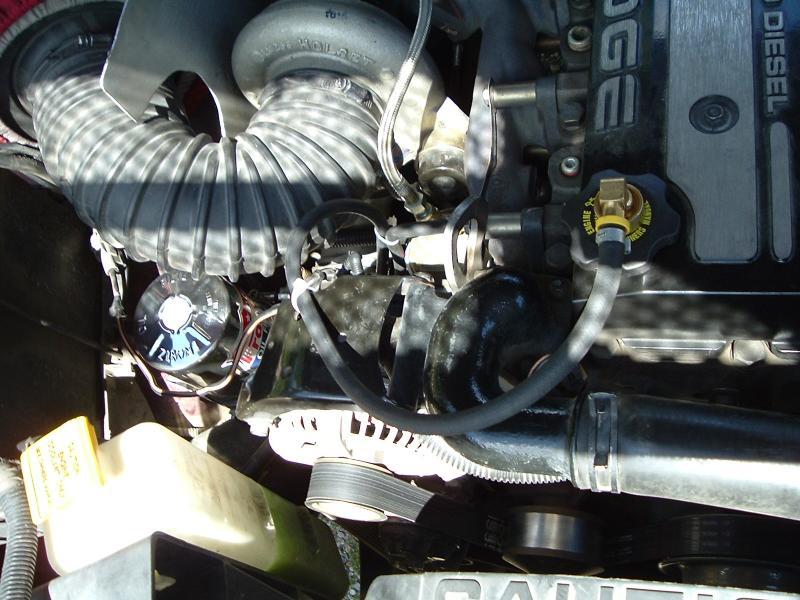

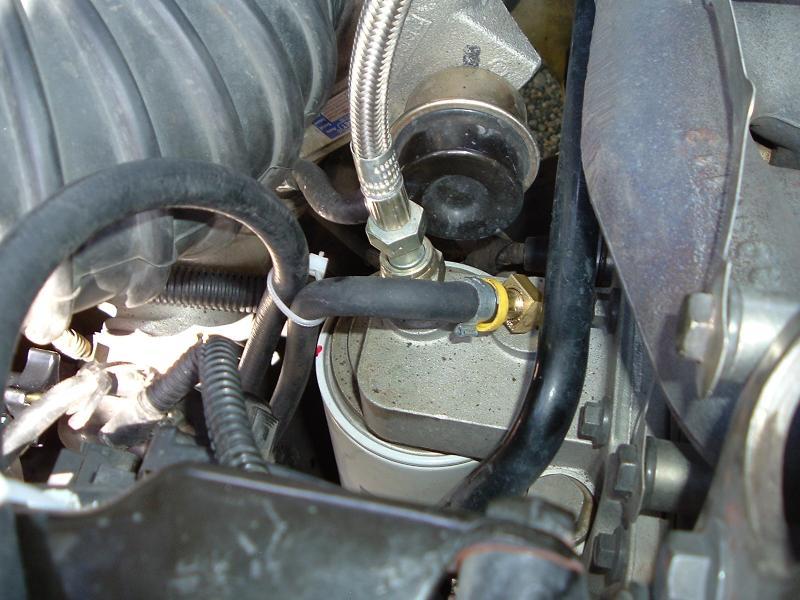

Here is the Frantz Filter... Where the oil supply comes from... Where the oil is return too. Fresh TP and spent TP Reloaded and ready...

-

80,000 Miles......No Full Oil Change

Well with the Frantz Filter it gets oil feed from the oil filter housing and returns it back to the oil cap on the valve cover. So you can remove the setup anytime you wish.

-

Failed emissions :(

Contact ISX he's the site P-pump guru... He would know exactly what to do to get you to pass then get you tuned up for the long haul...