Everything posted by Mopar1973Man

-

HY35 to HX35 swap

Really simple... Pull the five bolts and replace this flange with... http://forum.mopar1973man.com/attachment.php?attachmentid=2223 This one... http://forum.mopar1973man.com/attachment.php?attachmentid=2224

-

Check Gages Notification

Pay attention to the gauges... I'm going to bet its a oil pressure issues... Excessive time to build oil pressure...

-

Installing edge comp, need help

Its going to be a 3 pin plug down by the ECM and the driver side engine mount. It will have a weather cap over the end of the plug typically...

-

Cummins thermostats

The one just up from the heater core... That is the blend door...

-

HY35 to HX35 swap

By looking at the pic it loks like you could swap the pipe flange from a clamp style to the flared style by swapping with your old turbo. so then your down pipe would hook up...

-

Troubleshooting dead end on dead pedal. Apologize for a long thread in advance

Grid heater draw 195 Amps the alternator produces 120 Amps... So yes the voltage will fall some while cold starting... But typically doesn't drop below 12 volts... As for the grid heater they typically come on for the length of the Then once the light goes out and you start the truck then the grid heater cycle on and off as the engine is idling to mantain good manifold temp. Now once your rolling 20-25 MPH the grid heater are cancelled completely. If you disconnecting your batteries make sure to do the APPS Reset and re-calibrate it for the ECM.

-

HY35 to HX35 swap

I wish there was a pic of the exhaust housing...

-

Help no fuel to filter

AirDog, Raptor, and FASS (not FASS DDRP) are designed for diesel application and with withstand just about anything. As for the AirTex... There is several that swear by them but once again the manufacture were to stand behind it then they would have a long term warrnty like the big 3... As for getting the most out of a AirTex is to relocate the pump near the tank and get a big line kit... By the time you do all this you price will be close to that of a Raptor or a FASS 95...

-

Blue Smoke During Cold Starts

20*F might show a bit of hazy blue smoke... Even mine does it on cold morning when unplugged and left out in the cold. It might stumble a few beats but typically straightens out... But you'll notice a very light blue haze of smoke. But like I said before if the smoke is heavy and looks like ISX video then there is a pump issue...

-

Cummins thermostats

It not much really... Look closely the blend door is in the full cold position now. The long flap would rotate up and to the left to divert the air through the heater core. So the shaft moves about 45* angle at the most.

-

Need heat in my Cab

On the 98.5 to 2002 the A/C is used in the MAX A/C, A/C, Bi-level, Floor/DEF and DEF modes... All other positions shouldn't use A/C...

-

Cummins thermostats

As for the stepper motor that can be dealt without pulling the dash but if there is something interfering with the door moving like debris you'll have to pull the HVAC out..

-

Blue Smoke During Cold Starts

Blue smoke or just a haze of it is a fine on cold mornings... But when that blue haze is like a ground fog and stays for several minutes its time to look at the injection pump.

-

MPG's should be next to zero, soooo why are they still the same?

Just for a baseline number I pulled 16.5 MPG from Home to McCall, ID and back to Home 74 mile trip to go grocery shopping. Weather today was 43*F and thw IAT temp was 83-85*F most of the trip. So as you can see just the few degree rise from the video has gain back a bit of it... Tomorrow I'm going to play with my resistor collection and get a temp close to 100*F IAT and do another run at 120*F and see if there is a difference...

-

Cummins thermostats

Last time I measured my dash vents I was blowing 147-156*F out of the center vents... But let me pull out my thermometer again and check again with winter cold weather...

-

MPG's should be next to zero, soooo why are they still the same?

Let me play with the idea... I'm sure there will be a impact of some sort...

-

MPG's should be next to zero, soooo why are they still the same?

That's the thing by the time I cover about 20 miles then it levels out ot about 16-17 MPG... But that first fire up of the morning cold is my killer... Trust me I know why all the diesel leave there trucks idling. It cheap to leave it idle than starting cold and wasting fuel to warm it back up. At least for the computer controlled trucks. Also remember there is very little flat ground here in Idaho so either way I travel I'm either going up a slight grade or down a slight grade. Going south like I did I'm on a slight grade for 20 miles going from 2,800 to 3,500 in 20 miles... Or going south 20 miles and drop from 2,800 to 1,800 feet. Every road out here follows a creek, stream, or a river so it goes up or down regardless... Now even in the summer time I hit much better number going that direction I'm typically doing about 16-18 MPG by the time I'm in New Meadows proper I'm still hitting 22 MPG. I done another run last year from Home to Cambridge ID driving 55 MPH. When I got to Cambridge ID I'd barely pulled 15.9 MPG but the morning temps where like 25*F and IAT was 65-70*F the whole way. Then by the end of the day the temp had rose outsie and weather warmed considerable amount 65*F outside and I was able to hit my IAT mark of 95-100*F and BAM! Instant jump... I was back to 20-21 MPG... But remember also I've got changes to the vehicle too. Winter fuel, larger and heavier tires, colder temps, etc. So the loss is my typical...

-

Cummins thermostats

This help? http://mopar.mopar1973man.com/cummins/2ndgen24v/hvac/heater/heater.htm

-

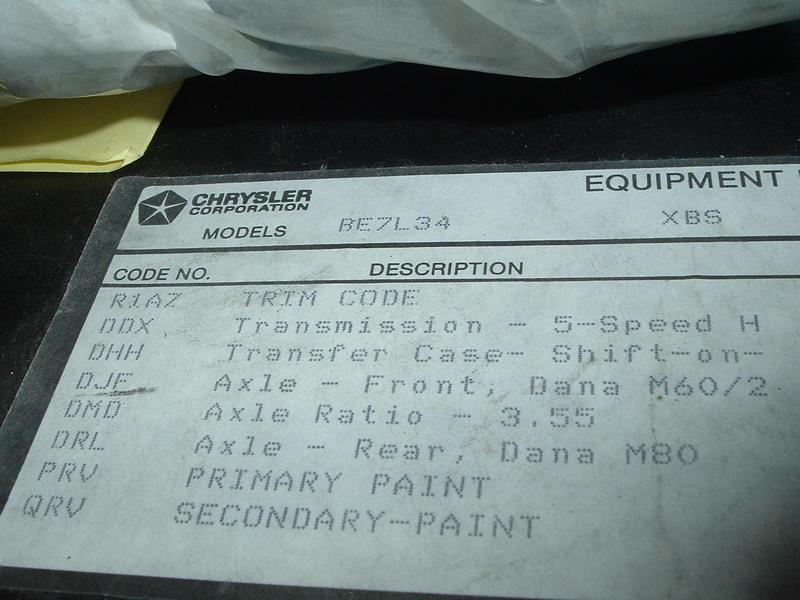

What gear ratio do I have

-

What gear ratio do I have

Give you a clue... I've got 3.55 gears...

-

Troubleshooting dead end on dead pedal. Apologize for a long thread in advance

I wouldn't worry about the slight voltage wander... When you start worrying is when you have +/- 0.1 volt changes... But a +/- 0.001 nothing to worry about...

-

Help. Can't find info on green vacuum line.

Geez... Feel the love... At least you could of paint my truck the right color... Now I feel better...

-

Quite dissapointed in mileage

Technically it would be like just subtracting the 25 from the 75... So it would be the same as driving 50 MPH. Simple logic...

-

Dear Santa

Right on! 2 thumbs up for that!

-

...And then the fight started!

This little selection from my megga-wag friend Brian: One year, I decided to buy my mother-in-law a cemetery plot as a Christmas gift... The next year, I didn't buy her a gift. When she asked me why, I replied, "Well, you still haven't used the gift I bought you last year!" And that's how the fight started..... ______________________________ My wife and I were watching Who Wants To Be A Millionaire on TV while we were in bed. I turned to her and said, 'Do you want to have Sex?' 'No,' she answered. I then said, 'Is that your final answer?' She didn't even look at me this time, simply saying, 'Yes..' So I said, "OK, then I'd like to phone a friend." And that's when the fight started... ________________________________ I took my wife to a restaurant. The waiter, for some reason, took my order first. "I'll have the rump steak, rare, please." He said, "Aren't you worried about the mad cow?" "Nah, she can order for herself." And that's when the fight started..... ________________________________ My wife and I were sitting at a table at her high school reunion, and she kept staring at a drunken man swigging his drink as he sat alone at a nearby table. I asked her, "Do you know him?" "Yes", she sighed, "He's my old boyfriend.... I understand he took to drinking right after we split up those many years ago, and I hear he hasn't been sober since." "My God!" I said, "Who would think a person could go on celebrating that long?" And then the fight started... ________________________________ When our lawn mower broke and wouldn't run, my wife kept hinting to me that I should get it fixed. But, somehow I always had something else to take care of first: the shed, the boat, making beer... Always something that was more important to me. Finally she thought of a clever way to make her point. When I arrived home one day, I found her seated in the tall grass, busily snipping away with a tiny pair of sewing scissors. I watched silently for a short time and then went into the house.. I was gone only a minute, and when I came out again I handed her a toothbrush. I said, "When you finish cutting the grass, you might as well sweep the driveway." The doctors say I WILL walk again, but I will always have a limp. ________________________________ My wife sat down next to me as I was flipping channels. She asked, "What's on TV?" After a thoughtful moment I said, "Dust." And then the fight started... ________________________________ Saturday morning I got up early, quietly dressed, made my lunch, and slipped secretively into the garage. I hooked my boat up to the van, and proceeded to back out into a torrential downpour. The wind was blowing 50 mph, so I pulled back into the garage, turned on the radio, and discovered that the weather would be bad all day. I went back into the house, quietly undressed, and slipped back into bed.. I cuddled up to my wife's back, now with a different anticipation, and whispered, "The weather out there is terrible." My loving wife of 5 years replied, "Yes...and, can you believe my stupid husband is out fishing in that?" And that's how the fight started... ________________________________ My wife was hinting about what she wanted for our upcoming anniversary. She said, "I want something shiny that goes from 0 to 60 in about 5 seconds." I bought her a bathroom scale. And then the fight started...... ________________________________ After retiring, I went to the Social Security office to apply for Social Security. The woman behind the counter asked me for my driver's License to verify my age. I looked in my pockets and realized I had left my wallet at home. I told the woman that I was very sorry, but I would have to go home and come back later. The woman said, 'Unbutton your shirt'. So I opened my shirt revealing my curly silver hair. She said, 'That silver hair on your chest is proof enough for me' and she processed my Social Security application.. When I got home, I excitedly told my wife about my experience at the Social Security office... She said, 'You should have dropped your pants. You might have gotten disability, too.' And then the fight started... ________________________________ My wife was standing nude, looking in the bedroom mirror. She was not happy with what she saw and said to me, "I feel horrible; I look old, fat and ugly. I really need you to pay me a compliment.' I replied, "Your eyesight's damn near perfect." And then the fight started......