Everything posted by Mopar1973Man

-

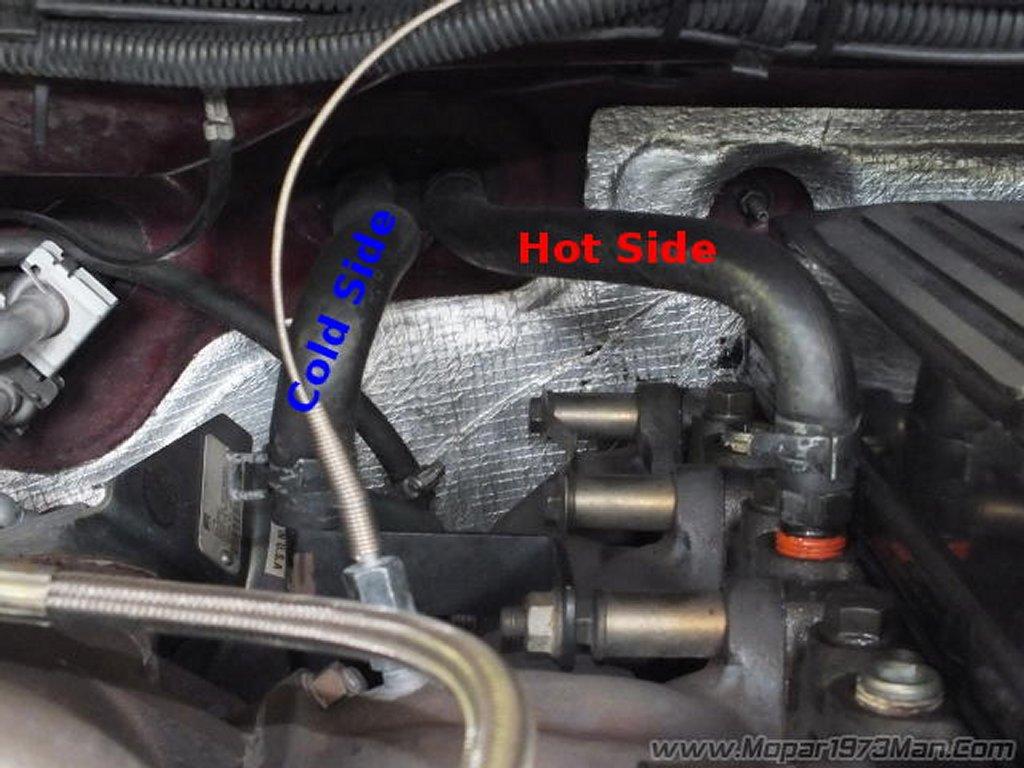

Quick Pic needed

What? Never routed like that. You might want to snap a picture.

-

Seat belt light stays on when belt is buckled

Should be only two wires. Just put a jumper between the two.

-

LED lighting - Interior lighting

Yes sir. 4kw @ 120 VAC.

-

W-T ground mod

Just remember you blow the fuse there is no resetting to get home. This is why I opted for resetable circuit breaker. If the breaker pops in short time then you know you've got a alternator issue.

-

LED lighting - Interior lighting

Why... I've got 120 VAC in the house. Standard outlets and lamp sockets.

-

Quick Pic needed

- Turbo Install

Kind of like myself wearing the hoodie that came with my 7 x 0.010 injectors.- Fuel heater necessary??

I would say yes. Subzero needs heaters.- LED lighting - Interior lighting

24 volt world for me at home.- Health and devices

Being I'm doing the bicycle riding for my health. I will admit that my blood pressure from the day I went in for my surgery I've managed to knock it way down. I'm still considered high but nowhere near what I was. Now the app I was using comes on my phone which is LG Health. It does track everything ONLY if you pack your phone around every where. I tend to leave my cell phone in my bedroom on home days. That doesn't track my daily movements. I went out and got cheap china made watch with heart rate monitor. Letscom Neat little watch battery life that is a full 7 days. Alerts from your phone. Then I can download the data of my travels to my cellphone. Now it tracks all my movement through the house and doing daily tasks like getting firewood or laundry. This little watch can even tell you how you sleep at night. Did you sleep deeply or light and toss and turn. As for the heart rate part it fairly right. I found that watch has to be snug to your arm for the sensor to work good. I'm going to do my first bicycle ride with it today. I report more on that trip. As for yesterday, I managed to walk 3 miles just doing my daily tasks here at the house. Alarms there is an alarm feature I like I've got it set up to remind me to take my hawthorn berry and multivitamins. It vibrates on your rist and shows a pill icon. Waking up to the alarm in the morning is really nice too. Vibrates little pulses, then gets longer and stronger. Tap the touch button and it stops. Recharging is simple the watch band pulls off the button side and it has a USB plug and just plug it in. It was fully charged when I got the watch and just needed a10-minute charge to activate the watch.- LED lighting - Interior lighting

Done something stupid last night. I made that one video and using the interior light switch on the dash. Made the video and got out of the truck and left the light on didn't even notice. 12 hours later the batteries are at 12.2 volts the next morning and the truck still started. These little LED light draw so little they had zero impact on the starting the truck. I had to share this.- new radio yaaay!

So you going to use a dead phone and fire up the Quadzilla. As for the CACA stereo no need for the phone. Just use a micro SD drive or USB thumb. Yeah, I'm going to switch over to USB 256GB thumb drive. I've only got 32 GB of storage total on my phone. I've got it to automatically pair up on Bluetooth. USB thumb drive quicker and hold much more. I've got another flip phone you can have I give it to you. Yeah... I've got to drive so much to take care of @MoparMom that I've got to have phone service. 13 hours a day, 39 hours a week I'm on the road. I'm looking at the safety factor. Talking on the phone through a stereo is kind of interesting works rather well. Texting can be done by voice commands which I'm also known to do. "Send a message to..." and the phone automagically open the text message box and you speak your message. Tell it to "Send" and it is gone. Works really well. Never have to look down. When the reply comes then the phone automatically tells me "someone" is sending a message and it read over the stereo. Even tell Google to "Open iQuad" and the Quadzilla app opens and starts up. Days of holding your phone and pushing buttons are long gone. Everything can be done by voice commands. I will admit sometimes Google can be a bit frustrating where you try and try and it refuses to understand the word that is coming out of your mouth. Duh?!- new radio yaaay!

The sound is OK. Remember I'm using my old stock speakers yet. My Kenwood had more power but this is fine so far. Plate I've used for 3 different radios. I bought the filler plate years ago back at WalMart as a kit. More radio shops carry them. Why? Use a Micro SD card it holds much more for music. I'm going to try my thumb drive I've got a 256 GB one and the stereo has a USB slot. A newer smartphone won't do you much good being there is no service. Being that Oregon is a handsfree state and Idaho is going to be one soon. I might as well upgrade to use a normal smartphone for phone call without handling the phone. Using a use phone without service defeats the purpose of the bluetooth. If you want music only on this head unit just buy a Mirco SD card 256 GB for $20. That one SD card will hold a total of 365 700-minute audio CD's.- 2000rpm max and no codes.

Most all NAPA stores have an alternator bench tester.- new radio yaaay!

I jumped in as well. Finally got cheap $39 China Made stereo that has bluetooth. It can play video files from micro SD card. Bluetooth music from your phone as well as picking up phone calls. Back up camera is included. I'm holding out on the camera for right now it just too cold to lay on the floor routing wires over a frozen frame full of ice and slush. Very small unit in size. No CD ability. Even comes with two remote controls. I'm going to try the steering wheel remote and see how it does. https://www.amazon.com/gp/product/B07BLVWWG4/ref=ppx_yo_dt_b_asin_title_o01__o00_s00?ie=UTF8&psc=1 I tend to have all my MP3 file on my phone already and get all my new music from MP3Juices.cc .- Autocomputerspecialist

Make sure you get ahold of @pepsi71ocean and give a review of this ECM/PCM provider. Need to keep a running tally of different shops and reviews. This helps other get good idea where to go.- 2000rpm max and no codes.

Even stock setup with a fresh alternator would be in the 0.030 AC volt range or 30mv AC volts. To be 0.57mV AC I don't think is possible. This could be because its a low grade DVM and not capable of measure varying AC frequency.- 2000rpm max and no codes.

This is why I suggested verifying with a bench test to make sure that its not just a "Cheap DVM" that can't measure odd frequencies.- Cruise, wiper solvent motor?

Depends. Automatic transmission - The Steering wheel controls are received by the Central Timer then past on down the CCD Network to the PCM. Where the PCM talks to the ABS module to get road speed and then controls a vacuum motor pulling the throttle. This is because the throttle valve on the transmission needs to sense throttle position. Manual Transmission - The Steering wheel controls are received by the Central Timer then past on down the CCD Network to the PCM. Where the PCM talks to the ABS module to get road speed and then controls the ECM directly. (Fly by wire). As for wipers it could be the multi-function switch in the column is worn out.- Autocomputerspecialist

@Auto Computer Specialist is in Florida. I had to make sure to make my phone call before 2pm MST. I would call first thing in the morning. I've always gotten the receptionist in the morning hours.- Wait to start delay

Yea... Its a corrupt ECM if the WTS is lagging now. this is a sign its having trouble booting up and getting to the first command to light the WTS light.- Autocomputerspecialist

Remember there based in Florida so be aware of time zones.- Dead tach, water temp & oil pressure?

Either P1698 or P1694 codes. One is PCM failure on the net. Then the other is ECM failure.- Dead tach, water temp & oil pressure?

Go over the articles look up P1698 code and then look for the CCD network article. Then you'll want to test your alternator and do the W-T ground mod. As for CCD error double check the big connector in the PDC and the two connectors near the valve cover on the cowl.- 3rd gen brake conversion on a dually

Better off with an exhaust brake. This set of brake pads are going to clear 200k miles. Not worth it still doesn't change the wear aspect upgrading to 3rd Gen brakes. - Turbo Install