Everything posted by Mopar1973Man

-

Diagnose lack of heater core heat output

Supply is the hose coming from the head. Pull the hose off and check to see if the fitting is plugged up. Also, it could be the heater core is plugged up and not flowing. This will all the coolant flow to slow and cool in hoses. It's only a loop from the head fitting through the heater core to the return to the steel pipe heading to the water pump. Any restriction will reduce heater performance. 99% of the time the heater core is to blame because of a lack of coolant flushes.

-

NV450 5speed blew at 184k miles.

Ummm... Might be careful making too thick...

-

NV450 5speed blew at 184k miles.

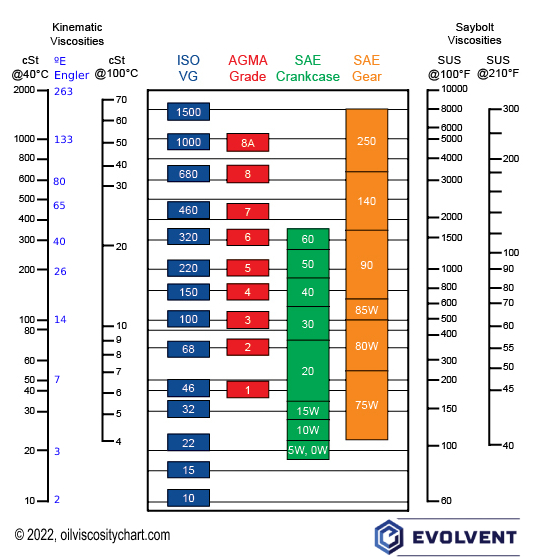

I would rather have a proper fluid than use a product that's too thin and have to add other products to protect the gears. Like Mobil 50 or Valvoline 50 is designed for Eaton Fuller 10 Speed manual transmissions used in over-the-road trucks. So, that would be like the PennzOil Syncromesh that people use which is actually too thin to make the GL-4 grade. In this case, people would be making up for the overly thin PennzOil Syncromech with Lucas additives. The more HP/TQ you make the thicker the fluids have to be to protect the gears teeth and the bearings. Thin fluids may be desired for smooth shifting and to this day I've not had a single issue with shift quality in my NV4500 running 50 SAE Transmission fluid. Then there is Valvoline 75w-90 which is rated both GL-4 and GL-5 which is a no-no why? Because GL-5 will cause damage to the syncros.

-

Firewood run mishap

No ATF. I had to flush mine out I got it done 4 days after. The seals in the system may not be compatible with ATF. 1989 to 2002 is all power steering fluid. No ATF. 2003 to current are all ATF systems. Why? Dodge dropped Saginaw steering gear for Ford Steering gear. In a nutshell power steering fluid is thicker viscosity wise compared to ATF. Power steering fluid is more like hydraulic oil.

-

W-T Ground wire mod - Informational warning

When your buying ring terminals for the alternator don't go cheap and buy just larger crimp rings. Make sure to get a good copper ring for the alternator lead. I thought yesterday my alternator quit being the circuit breaker didn't trip neither did the fuse for the field wire. I kind of messed up yesterday and was trying a pop a rib out yesterday so I asked Mark to swap out the alternator with our donor truck here. He started pulling my alternator off and the charge lead fell off. The ring tore on one side and the rest of the ring wasn't strong enough to hold the current and poof! It melted and opened the circuit for charging. I highly suggest using copper terminals and good quality terminals that can handle the high current.

-

NV450 5speed blew at 184k miles.

Because the smaller input gear has wear through the hardfacing of the gear teeth which get brittle and snaps off. First place it goes is down on the countershaft and gets mashed up which now breaks those teeth. I'm of a believer that the factory lube is just too thin. Look up above 75w-85 is equal to 10w-30 engine oil. My 50 SAE trans mission fluid is 90 weight gear. Better high temperature protection when towing or working the truck hard. Just consider the viscosity off the oil at 200 or 220°F oil temperatures.

-

NV450 5speed blew at 184k miles.

Input gear has about 350k miles. 5th gear was about 300k miles. I've been only replacing damaged parts.

-

Map Sensor Trouble

Need a 6 sided socket either 1 1/16 or 1 1/8 socket but it's a must for 6 side. Not a 12 point.

-

NV450 5speed blew at 184k miles.

Actually the factory fluid got thin allowed the hard facing on the gears to wear and then snaps a tooth off and cascade failure occurs. One of the few reasons I switched to 50 weight gear lube. My last failure was the same two gears. Here is even my input and countershaft gears. You can clearly see on mine the lower tooth has serious wear into the hardfacing.

-

Curse of the 5th gear nut!

Matter of fact @Doubletroubletransmission just blew up his tranmission. Broke the teeth off the input shaft and the countershaft below. Bearings are wiped out too. I was looking at some of the photos and saw where the hard facing on the gear teeth was worn down and grooved. Thicker lube is a bonus 75W-85 is only 10w-30 engine oil. The 50 SAE transmission fluid I use is actually 90-weight gear lube. It's a synthetic GL-4. I know the 2 buckets I've got now both Valvoline and the Mobil 50 no longer show GL-4 rating. I'm still using 50 weight and plan on swapping the ATF+4 out of Thor (2006) and changing to 50 SAE as well. ATF+4 is even thinner than any of the fluids listed.

-

Curse of the 5th gear nut!

Strange 472k miles I've never had a 5th gear nut issue. Now what I had problems with.... First off the factory gear lube 75w-85 synthetic is too thin especially when heated to above 220°F. It was causing wear of the gear hard face and cause the gear teeth to break. I've broke 5th gear (smaller one on the mainshaft). I've broke the input gear. Then had issues with syncros being I got two sets of defective brass syncros. This is why I'm using 50 SAE Transmission fluid which is the same stuff used in Eaton Fuller 10 speed transmission. Food for thought the 75w-85 is equal to 10w-30 engine oil for viscosity.

-

Website is going to get busy again.

Well maybe, and nope. AlmaLinux 9 8 GB of RAM 160 GB Hard Drive 8 CPUs Intel Interworx Control Panel Cooking skills are rather poor but she is a great server. (Think restraunt server.)

-

Website is going to get busy again.

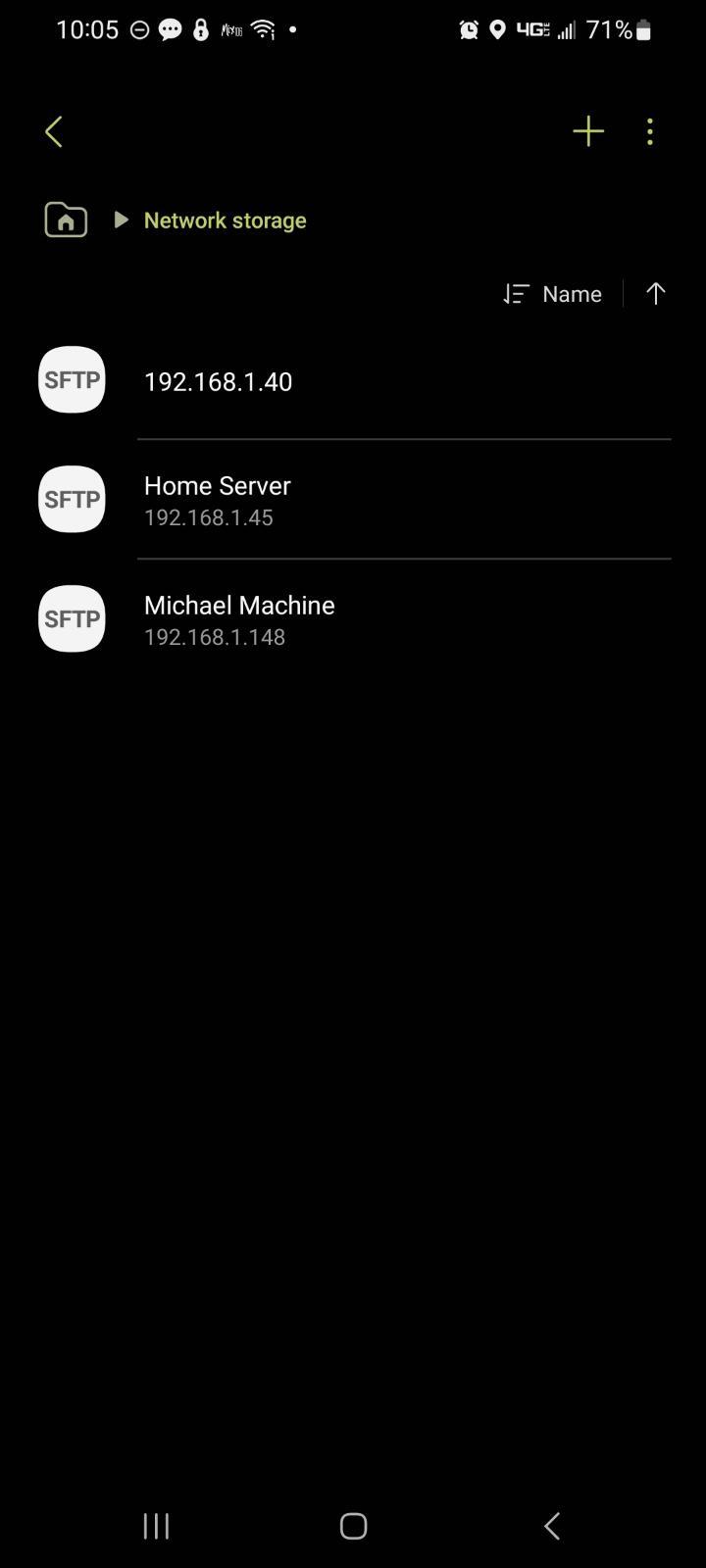

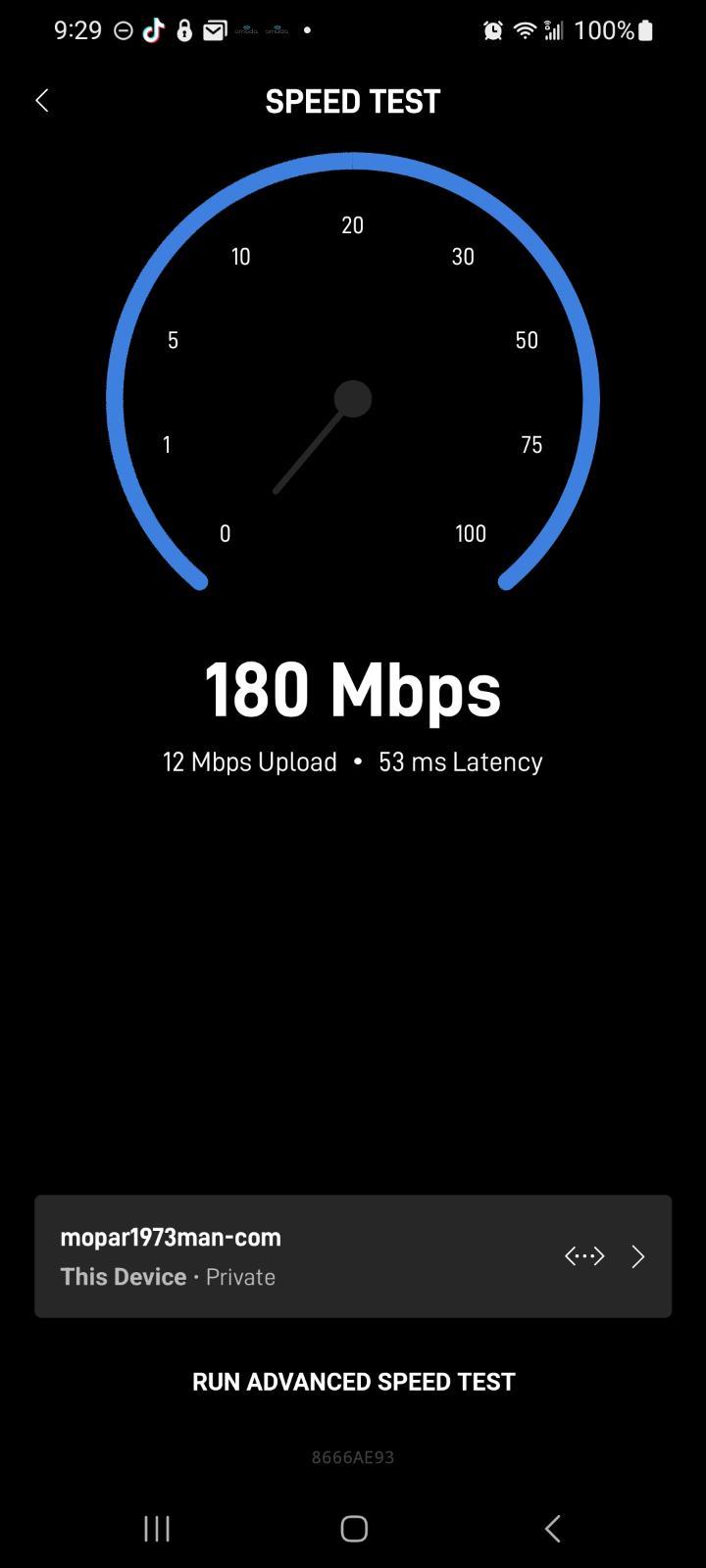

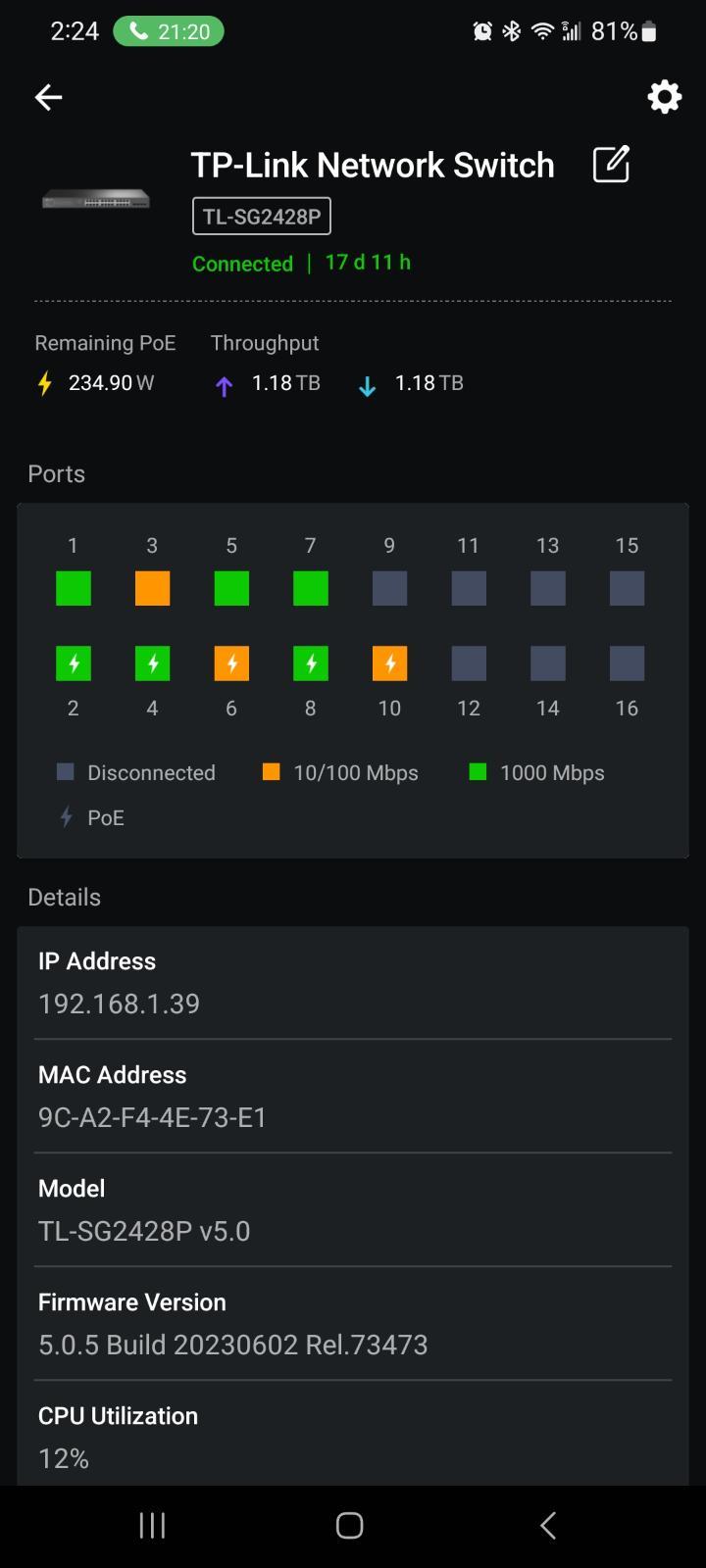

I've got a lot done. Flooring is complete in the living room. I've got my computers back up. Both Michael and Server up and running. Now with the network built but not quite finished. This allows me to run the server for doing my backups of the website back home which I'm going to make sure everything is backed up here just in case. Being my other thread I've purchased the new server with the hosting company. Here you see my 28 port managed network switch and the little box is my gateway / router. I'm getting everything ready for the big move.

-

My personal network

Mopar1973Man replied to Mopar1973Man's topic in Linux Computers, Networks, and Servers's Linux Computer SupportMy TP-Link Gateway / Router (ER605v2) showed up today and was fairly easy to hook up and configure. Compared to the switch it's a tiny unit. I'm not feeling all that hot today, I'm worn out and didn't sleep too well last night. I figured I'd get the gateway/router hooked up and running so the network here continues. Amazing how much device traffic I have here and how well this system is handling all this. The little box on top of the larger switch is my gateway/router for the internal network.

-

Website is going to get busy again.

-

My personal network

Mopar1973Man replied to Mopar1973Man's topic in Linux Computers, Networks, and Servers's Linux Computer SupportAfter doing some research on Starlink it is a rather secure Internet provider. I found out since they use CGNAT for addressing the internet it's nearly impossible to even address any device inside my network. Kind of a bummer for me I want to port forward several things off my home server so I could access from anywhere in the world. Nope CGNAT prevents this from happening. I've had several freak out about my use of Tiktok and how anyone can steal info from my phone. This is not possible while I'm at home since no device can be addressed from the outside world. How do I know this? Funny during my server set up I wanted to remote download all the website data and point it back to my home server. There is no response from my home server even calling out to my public IP address and even having port forwarding point that call to my server. Nope. No response. Now within my home network I can call my server and access the data I need. Yup I can access both machines from my phone at home but can't from the field.

-

Diagnose lack of heater core heat output

The heater hose going to the head is the supply and should be the same temp as coolant. The other hose going to the steel tube is return and should be 50 to 70 degrees cooler than coolant temp while the fan on high and temp set to to full heat. If they are both equally hot then the heater would be plugged up possibly from debris in the block. Typically on my Quadzilla I range from 186 to 202 degrees. Running still a Napa thermostat. I flush coolants on a regulat schedule. Vent temperature I typically measure about 160 degrees out of the vents on full heat.

-

My personal network

Well, I'm sure a lot of you are curious about what I've been up to in the background. What I've been doing lately to prepare for the server swap is creating my own network at home. This is not your typical network setup. I've got 2 indoor WiFi heads one for the main house and one for the shop. Then I've got an outdoor WiFi head as well. This is all tied back to my 28 port PoE (Power On Ethernet) managed switch. Here we go... Starlink is my provider for the Internet. So far I'm extremely pleased with my service and price per month. Starlink is my source of internet and I had to order the optional ethernet port so I could run a wired network as well. No problem it was easy to hook up and fairly cheap to purchase. Now coming off the Starlink to my TP-Link 28 Port Managed Network Switch. I've got 250 watts of power for any PoE-enabled device. PoE stands for Power On Ethernet so the network switch provides the power for like my cameras and WiFi heads. This makes the setup very very easy being I just have to run cable from the switch to the device. Why all this? Simple it gives me a way of managing internet usage and allows me to firewall my whole network from the outside. Well not quite yet. I'm missing a Gateway that I ordered tonight which allows firewalling, port forwarding, and other firewall tasks. I've got security cameras watching over the property and the customer's vehicles here in the yard. Then I'm providing WiFi and cell service (Verizon). Now this is where some security comes in. I've got so far 2 WiFi channels you could use. Currently, Mopar1973Man is my full-access WiFi currently no restrictions. Now then there is Mopar1973Man Guest I got the bandwidth restricted to 5 Mbits down and 2 Mbits Up. Now I'm downloading large amounts of data from Mopar1973Man.Com I can now do it securely and not worry much. I've taken @MoparMom computer formatted the hard drive and created my own home server that does the dirty work that I don't want on my machine. Like today I did another full server backup and was able to store it in my home server. My cameras are set up over an SSH connection (Secure SHell) and as soon as any motion is detected the camera creates a video file on my home server and writes the video clip to the hard drive. Now going even further. Another reason for all this is protection from EMP pulse. You have to remember all data is stored on magnetic hard drives or SSD (Solid State Disk). As a matter of fact, I use both. So even the current backups are not secure being one EMP pulse could wipe it out. Now I'm building up a way to take these massive backup files and convert them into chunks that I can burn to DVD DL (DVD Dual Layer) which is 8.6 GB per disk. Then if I get this all written to an optical disk then it won't matter about EMP. Even if my computers are destroyed I've still got everything I need to restart even a new computer and be up and running quickly. Hard to believe after 23 years of being here on the internet I've got close to 65 GB of data on this server. That is my other issue. My current server I'm on has run out of time. CentOS7 is considered obsolete. I've been busy test-driving software I can get ahold of and ensuring I'm not getting caught in a corner with software issues, The website will be leaving CentOS7 Linux and switching to AlmaLinux. I've downloaded AlmaLinux and it's also a Redhat Linux Family and seems to be a better operating system. What I did was install VirtualBox and installed AlmaLinux as a virtual machine. The only thing I've not really studied hard is the Interworx control panel for the server. It seems like a better environment over cPanel without the expensive license I pay monthly on cPanel. Anyone out there that wants to try Linux I'm more than willing to teach you and help you install the Linux to a PC and get you set up. Just keep in mind Linux world does not have viri issues or malware being all Linux software is open source meaning you can download the source code and review the code for weakness if you wish. The beautiful trick is Android and Linux are both in the same family of Linux. You can bind your cellphone to a PC and that way you can use cellphone functions without picking up your phone. Being all the servers I work with are all Linux there isn't any need for expensive conversion software like Windows uses to work with Linux networks. Always remember Linux software is FREE, no cost, no price.

-

Not starting straight away every time

Wait to Start light should always come on for a bulb check even if you don't need to wait to start. Could you check for error codes if there is a P0381 then it's a bulb or circuit issue between the ECM and the wait-to-start light. Harder starts typically I first think about the air in the fuel or air leak on the fuel system. Yeah, I know that the VP44 injection pump can also fail without codes. But typically there are other issues that come up where performance suffers like MPG's, or just running performance. Error codes just usually mean an electrical circuit or sensor is not working like it's supposed to.

-

Firewood run mishap

Wednesday (Oct 17, 2023) we all headed out and got up to the west side of Florence ID and got to our old spot. Damn It! Our wood spot has been bone-picked. We moved to another spot on the mountain and found lots of wood but bigger-diameter trees. No biggy. So I started to back up the trailer to park it out of the way and the steering started to whine. I shut down instantly and got out and you can clearly see the fluid came out of the top cover of the steering box. Being Beast has all of Thor's tools I just simply got the right wrench. Now checking the top cover 2 bolts were loose. I snugged up the bolts and no what for fluid? DISCLAIMER: NOT A PERMANENT SOLUTION JUST A BAND-AID! I just happened to be lucky I had 5 quarts of ATF+4 in the truck and a transmission funnel. I poured ATF fluid till it ran over the top of the reservoir. It least filled with fluid. We continued our wood gathering and had no issues. Now an old man years ago told me, "Even the wrong fluid is better than no fluid!" In this case, I was lucky I had the ATF in the toolbox yet. Now I've got to go buy a gallon jug of power steering fluid and flush the ATF out of the system. Why 1989 to 2002 Was Power Steering Fluid vs. 2003 And Newer Are ATF+4 WARNING! - 1989 to 2002 Dodge Ram trucks all took power steering fluid. DO NOT use ATF+4 as a fluid substitute being the seals are not compatible with ATF or even ATF+4. This is why the 2003 and newer trucks run ATF+4 because Dodge did away with Sagnaw Steering Boxes and switched over to Ford Steering Boxes. This is why all 2003 and newer trucks have ATF+4 for power steering fluid. So shortly I'll be building a power steering flush article.

-

Website is going to get busy again.

Alright... Finally, I got the server here finished. I now offloaded all this background stuff to MoparMom's old computer. Uninstalled the network software and all the camera footage moved to the new Server here at home. Now we are going to be looking into doing the server swap very very soon. I'm looking at maybe sometime this next week if things go right. Personally me right now I'm kind of struggling with my lower back and my hips from chasing firewood.

-

Pilothouse/RAM3500 build

Just was showing off your photos to my friend of your Cummins Quad Cab.

-

#6 intake rocker cap/socket came out

Remove the push rod and roll it on a piece of glass or flat steel table. If it wobbles when rolled it's bent. You can purchase a new rocker arm set from @dieselautopower which I've done for one of my clients that #1 exhaust did the same thing. I ordered just one rocker arm set and did valve lash on the single set and was done.

-

Website is going to get busy again.

Update for tonight. I started building up my server machine. Got my security cameras all swapped over to the new home server. Then during my Ubuntu 22.04.3 install I opted for partitioning the drive up. I've got 2 TB in that machine. Root - 20 GB Home - 250 GB Camera - 820 GB Website Backup - 820 GB Why? So when I'm in process of doing the server swap I'm going to have a full copy of the server before and after. Then thinking ahead if EMP happen to be used in the future I'll have another copy here. Then I'll burn all the website data into DVDs which are not magnetic but optical so for a good copy will be saved. I'm planning on the home server to capture a weekly backup here at home. No matter what I'm doing everything in my powers to be double sure nothing is lost. I'm done for the night.

-

Website is going to get busy again.

Dang... The Thumb Drive I've got is barely 8.1 GB empty and AlmaLinux 9 is just too big to fit. It's 9.2 GB for the ISO file. I tried the minimal version which has all the graphical parts totally stripped out. Welp. I'm going to head back to my tried and true Ubuntu 22.04.3 load that up on that machine and get rolling. Either way, I'll be still good here. I wanted it for a learning experience and a bench to work on the website. I'm currently creating the boot USB stick so I can get this machine up and running. Ubuntu is much smaller at 4.3 GB which will fit on this thumb drive.