Everything posted by Mopar1973Man

-

Frantz oil filter any input/updates?

I fell away being that toilet paper doesn't fit the can properly anymore. The filtler elements now are but more spendy and one one place to get them now. I like the idea of toilet paper and I could change rolls in mid-flight of any oil change. For $9 I could buy a 12 pack of toilet paper now you can only buy 1 filter... http://www.frantzfilters.com/synthetic-vs-cellulose-media/

-

1 EGT probe to 2 devices?

Here is my solution...

-

Getting the most from a LG G5 cellphone...

Basically every Tuesday, Thursday, and Saturday I make a 250 mile round trip for @MoparMom Dialysis requirements. While I'm on the road I wanted to make everything as easy as possible. From taking cell phone call, listening to MP3 music when FM radio fails. Entertainment (movies) for when there is nothing left to do but wait. Data logging for both MPG's and iQuad. Since I'm stuck in the truck for 13 hours 3 days a week I might as well be comfortable and capable of getting work done on web sites. Being now I run two business which is Mopar1973Man.Com and PrevailWebManagement.com. So I'm managing 5 web sites in total now. My truck is more comfortable than any medical waiting room. My WiFi doesn't have a firewall blocking important ports for reaching server control panels. Then taking care of members that call me on the road, not a problem with 4 speaker stereo even MoparMom can get into the conversation. Well, at least the space shuttle has more room than a Dodge Ram Quad Cab...

-

Getting the most from a LG G5 cellphone...

That allows me to hook up @Chris O. CCD Network tool that is hiding under the center seat. So I've now got 3 OBDII port laying there.

-

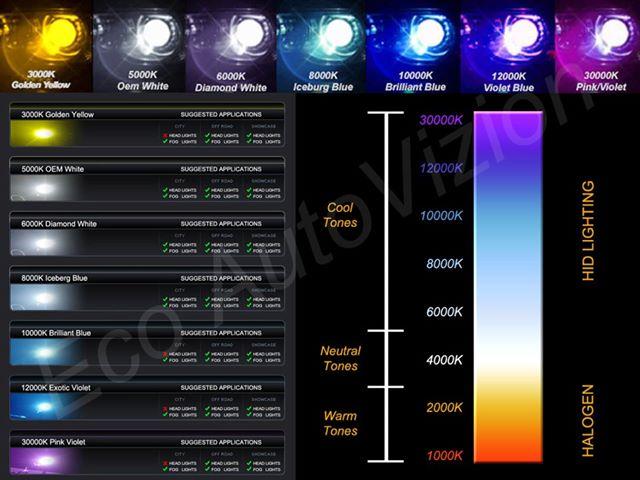

Headlight options

Good question... I'm not sure on the life expectancy of the bulb or ballast for total time. I do know you want to avoid getting the 50w ballast and bulbs they are known for shorter life span at the price of giving more light. As for the setup I got, I opted for the 35w ballast and bulbs. As for most of the members here, they went with the smaller H1 Mini Morimoto headlights. If you don't want to do all the custom fitting and just want to buy a fully assembled head lights... http://shop.retroshop.us/ProductDetails.asp?ProductCode=2G.RAM.RETRO

-

Getting the most from a LG G5 cellphone...

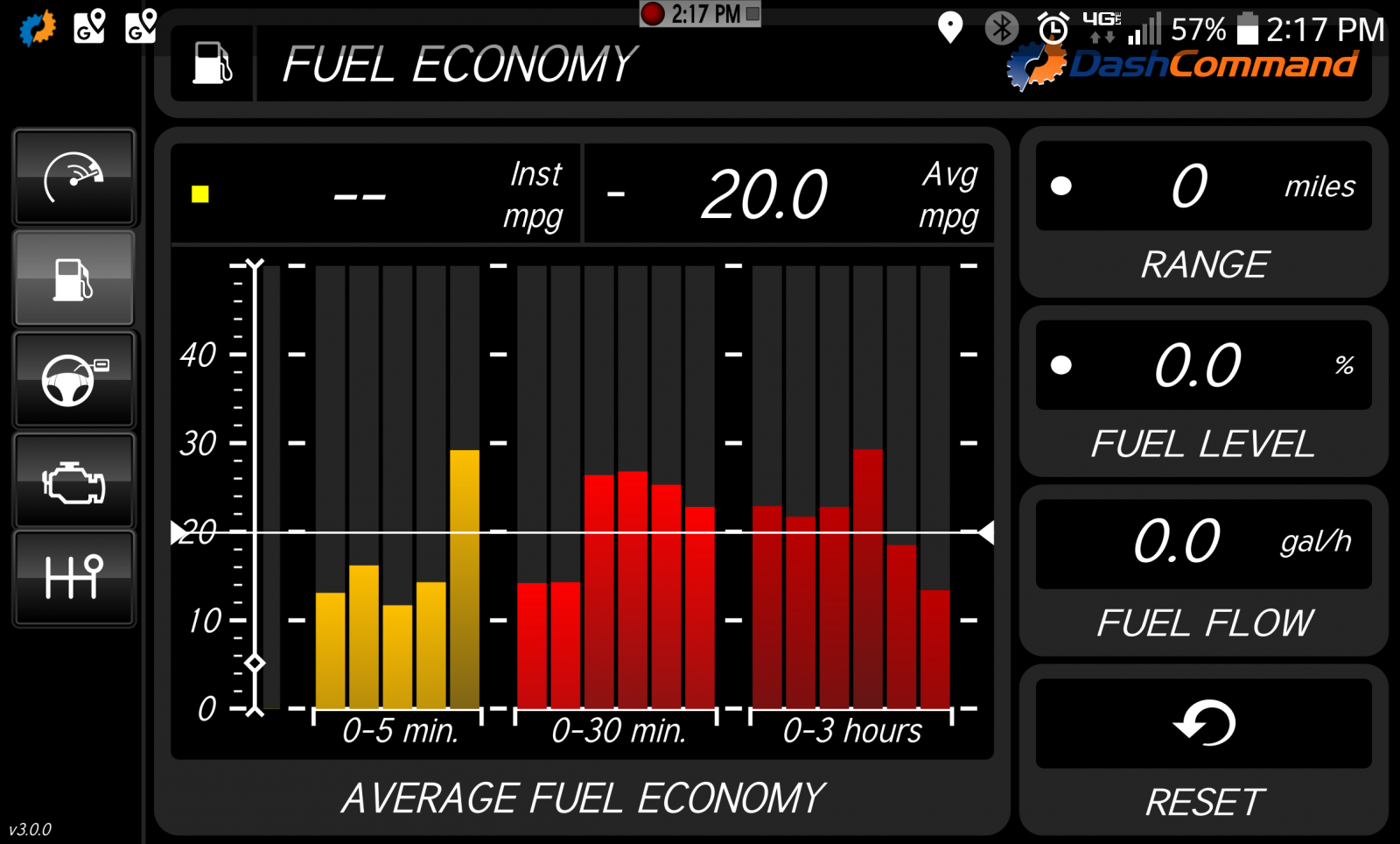

I've managed to get the most out of a single device... The device is my LG G5 cell phone. I recently picked up a gooseneck cell phone holder . This turned out awesome being it will bolt right to the seat frame on the passenger side there is a bolt you can loosen and mount the gooseneck to the seat. Now with a bit of work routing wiring and hiding the wires I've got it cleaned up as much as possible. So what can I do with this setup? My Kenwood stereo has an AUX audio jack so all audio is piped into the stereo speakers. This makes hands free cell phone calls really great. On my SD memory card I store music and movies so when I'm down in Ontario, OR and nothing to do I can pull up a movie lean the drivers seat back a bit and watch movies. If I've got business to do I can fire up the WiFi hotspot toss the laptop on the center console and get web work done on the road. As for the cell phone, I've got two apps that run all the time. That being Quadzilla iQuad App and DashCommand. My LG G5 cell phone can handle 2 Bluetooth signals at the same time. The second connection can be an audio device if I want. This has turned out to be quite the setup and really enjoy it for those long hauls back and forth to Ontario, OR. You can see the green aux audio cable in the stereo. That goes down to the cell phone. As for my power I've got a 3 port cigarette lighter dock. I routed it down to the floor near the transfer case lever. My GPS on my dash and my radar detector are routed down to this power point. So this is how I've managed to keep going and doing business as I travel.

-

Headlight options

These are completely legal and have proper cutoff. The on coming side of the beam pattern steps down to prevent blinding on coming vehicles. The test board picture really short cutoff but when layout on the highway the cutoff is way more pronounced. The step is right on the yellow center line. You can select the bulb color you wish too. I'm running 5k bulbs where lot of people like the 4k bulbs which lean towards the orangish tone where the 5k is leaning to the bluish tone. I thought the same thing for years that HID's are blinding illegal headlights. Only if you attempt a HID bulbs in a stock headlight housing without the lens and shutter. Now this is illegal... No lens and no shutter to contol high low beam. Reflector is not correct. This will blind people. https://www.amazon.com/1994-2001-Pickup-Crystal-Headlights-Conversion/dp/B06XJHRW4B/ref=sr_1_2?ie=UTF8&qid=1505327433&sr=8-2&keywords=dodge+ram+headlights+hid Where with the current headlight package I've got which is the Morimoto D2S. I've got the whole package. http://www.morimotohid.com/projectors/bi-xenon-mini-d2s-4-0-projectors.html Way different light setup and quality for sure...

-

Quadzilla Adrenaline V2 Testing

May I ask what other variables you need? There is also an "if then" statement between the 2 examples above. IF engine load is LESS than cruise timing load THEN... Math here is additional timing... IF engine load is GREATER than cruise timing load THEN... Have to watch the math here is reduction of timing...

-

Headlight options

I'll agree. The part of the problem is the secondary bulb reflector isn't all that great its a tall but narrow band of light. This is what is helping to give the distance but not wide enough. So now driven with OEM Stock, Sport headlights (relay conversion), and now Morimoto HID's. It is really wild to get on a long straight road and shine light a full mile down the road if not farther. Then having both side of a 2 lane highway lit up about 40-50 feet out in the ditch. Then on high beam create a light arc about 50 foot tall at about 1/4 mile out. My next upgrade when funds allow, is I'm ditching my 100w aircraft lights and ordering a set of LED PIAA driving light and fog lights. Sad to say the Morimoto HID drown my weak little 100w aircraft light so you really don't even see them any longer. Barely an orangish mark on the road.

-

Quadzilla Adrenaline V2 Testing

This makes way more sense to me seeing the math than your long speech above. See the math formula and being able to plug values into the variables and see changes it way easier to understand.

-

to good to be true

@dripley those are nice looking seats... Wow! Like you've start all over factory fresh again. I wish I could find a lucky strike like that. I've kept seat covers on mine most of life of my truck but I'll admit my driver seat cushion is getting tore up foam wise. The fabric is giving up on the left edge.

-

Quadzilla Adrenaline V2 Testing

The only setting I know of that is close would be "low boost timing reduct" which retards timing on high TPS, low boost moments. Then the fuel load timing which retards timing in low engine loads periods. From the Tunning page...

-

Quadzilla Shudder light throttle

Still got this issue but not able to alter the miss/stutter problem yet. I'm wondering if your right @Me78569 that something isn't flashing properly for value and has a dead hole.

-

1 EGT probe to 2 devices?

I'm the reverse I want to have all the gauges on the A-pillar and leave the Quadzilla App turned off. That way I don't have to pack my phone everywhere. But now with data logging the MPG I'm kind of stuck watching MPG logs on the phone.

-

Custom Quadzilla Tuning R & D Thread

Not exactly an answer either. I'm doing long runs every other day. My MPG can change from tank to tank without changing the tune at all. I can vary as low as 16 MPG on the low side and 19-20 MPG on the high side without changing anything on the tunes. Weather, traffic, road construction, idle time, etc. all will alter your final number. I did do a change. I dropped the OBDLink App and switched over to Palmer Performance App. Much better app and the auto connect to Bluetooth works properly so data logging of MPG is a bit more accurate now. Do mind you this is uncalibrated just imported my previous settings from the other app.

-

1 EGT probe to 2 devices?

That would be a mess having to have an oddball VDO gauge and 2 ISSPro gauges...

-

1 EGT probe to 2 devices?

Being pyrometer probes create very very small voltage and splitting the pyrometer probe to two devices will for sure throw the accuracy out the window for sure.

-

Quadzilla Adrenaline V2 Testing

So you're saying if I over advance for sure I would see higher load numbers from the engine? I'm going to assume that excess retarding will do the same in adding more engine load and EGT's go higher.

-

Custom Quadzilla Tuning R & D Thread

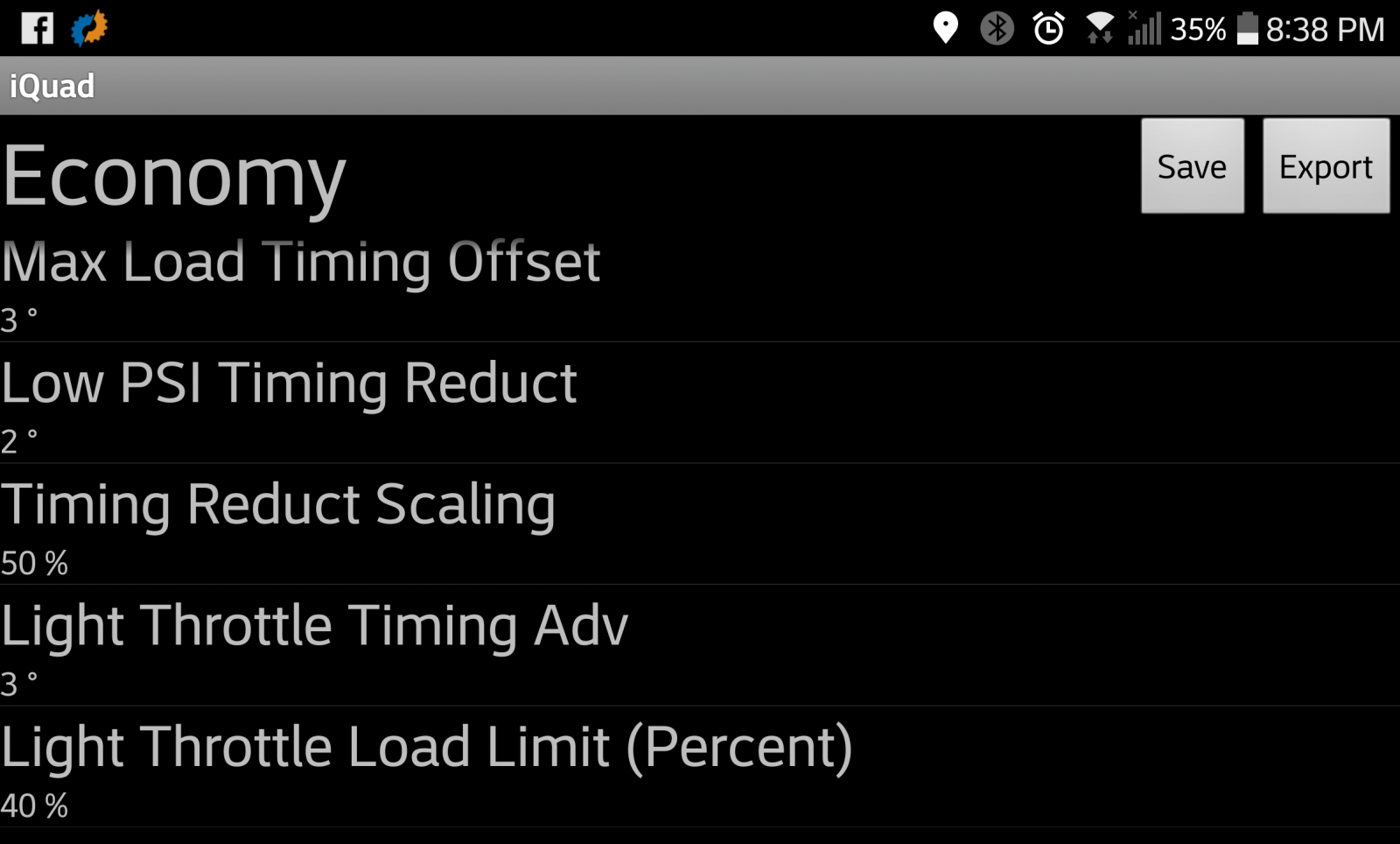

Fuel wise I've got that nailed down rather well and can create some pretty nice smokeless tunes or low smoke tunes. Now as for the timing. That is still a mystery that I'm still attempting to figure out what is optimal cruise timing then what is optimal performance timing. The only thing for sure I've got to play from is the Quadzilla factory default tune. To me, it seems rather mild for timing but not sure... Quadzilla tune page and the setting they called default...

-

1 EGT probe to 2 devices?

-

Quadzilla Adrenaline V2 Testing

So you are saying cruise timing you can crank up rather steep. Don't have to worry about the WOT operation Quadzilla has a load limiter that kicks out to the performance timing map. I'm assuming you talking about a performance state and not a cruise state here. Because now you talking more of retarding timing more so to reach the ATDC mark or goal as you say.

-

1 EGT probe to 2 devices?

Exactly what I've done. Don't attempt to share one probe for two devices it won't work.

-

Quadzilla Adrenaline V2 Testing

Still in all... I understand the stock hole in timing... No one has shown how to tell what is enough timing. Too much timing? Too little timing? How does a person find out what is the right amount? Like @AH64ID mention that since his larger injectors he doesn't need as much timing. Then dropping pilot injection. I know CR is a different system... Fueling wise we all can see in the mirror if we have the right amount of fuel to boost. Simply look in the mirror if there is black smoke you need to roll back the fuel in your fuel table. Timing wise there has to be a way to see what is too retarded or too advanced. Then you add all these variables into the mix. Which affect timing in all different ways. Fuel load timing, Low PSI reduct, Timing Reduct Scaling, Light Throttle Advancement and load limit. One person tune might not fit another because of injector differences, altitude, turbo differences, even engine differences. The BIG Question.... So how do we detect proper timing?

-

Quadzilla Adrenaline V2 Testing

What is the X axis in the table above? I can see the RPM on the Y axis...

-

Vulcan DS1-2 Draw Straw Upgrade