Everything posted by Mopar1973Man

-

Need A Personal Snow Plow But How Big?

Even on my ATV I did 1 size larger than the ATV. Typically they sell 48" blade for it I took the 56" blade to keep the snow from rolling back into the front tire on full tilt. My neighbors blade is 48" and his ATV will lose traction on that front wheel from the snow coming around that side of the blade. Like Mine bigging just that bit wider on full tilt it gives just that extra few more inches and keeps the snow away from the front tires. I know this is ATV vs. Truck but gives you a idea...

-

Rancherman Is A Yotahead...

Kind of like this thread... http://www.cumminsforum.com/forum/98-5-02-non-powertrain/950162-new-cummins-need-info-please.html Shainer said... I have a problem with that lazy answer as you'll see I still did what I could to help. I know for a fact that all forum software are weak in the search engine (internally). Even here. I could install Sphinx search engine but it would require a different server for us. But still in all I will not tell a person to search first. Even with all my work on the phone there is never two cases exactly the same. I've had times on the phone and got confident I had the answer sounds like a classic case of "X" only to find out it don't work. Now I'm scratching my head. Thinking up the answer to the unheard of case "Y"...

-

Oil Pressure Help

Just a quick note remember oil pressure sensors are not absolutely correct.

-

An "uh Oh" Moment

Time to hook up the clutch safety now right???

-

4 Wheel Drive, No More

Look like you going to rebuild you front axle. (Seal and bearing kit)

-

Air Dog Return Spring Shim

Mine took 2 shims being they are thinner than most washers. All based on how thick they are. More or less a test and try method.

-

Rpm Range, And Rear End Gears

Lets say I've crossed 1,400 a few times on fire calls and passing vehicles on the highway. But its only for max of about 10 seconds. 1,200 is safe to run. It just once past that no one knows how long any thing will last. One pyrometer gauge might be + few degrees and the other might be - a few degrees so who is to say what is safe? Like I said pistons are aluminum and they are cooled by engine oil so how long... Don't know. But as long as your below aluminum melt point you should be safe. I typically float 550-600*F at 55-60 MPH at about 2-3 PSI of boost. Typically can reach the 20's for MPG's...

-

Need Help Asap With Airdog

I bet that if you could wire that drill in to the 12V and mount it somewhere it would work better than AirDog. With all the people I talk to on the phone AirDog quality is at a all time low really.

-

Rpm Range, And Rear End Gears

Aluminium melts at 1,220*F (660*C). There is cooled oil sprayed at the pistons from underneath. So extended 1,200*F is safe all day long. But you'll notice the coolant temps will be elevated still normal but higher than typical. 1,000-1,100*F you will see less increase in coolant temperatures typically float about 193-197*F. Optimal for 20+ MPGs you want to get below 600*F and 5 PSI of boost.

-

Air Dog Return Spring Shim

Sad to say I've got a phone call of a gentleman back east that just lost his 4th AirDog in one month time frame. So each one lasted about 1 week a piece. The last one barely made 100-120 miles I was told. Since he's strapped for cash so he's going back around for another warranty pump number 5. Ugh. Such a wonderful product but total junk now. Reminds me of the vBulletin threads I read... http://www.theadminzone.com/forums/showthread.php?t=106727 http://www.theadminzone.com/forums/showthread.php?t=106441 Now you know why I swapped forum software. But Like as you read the older AirDog's like mine are like the older vBulletin 3 software rock solid and still working. Strange but true...

-

Anybody Rebuild Their Own Engines?

Ouch... Time to tear it down and get it sent off for rebuilding.

-

Changing A Starter In The Rain... (On My Lincoln)

Starter... That's easy. Now do a VP44 in a rain storm on the side of the mountain with no shelter, no power for a shop light, just a Mag Light stuffed in my mouth and wrench in hand while working under a tarp. Still got it done in 2 hours (bit slow).

-

Advice On Clutches

No joke. Quality part do cost more but do keep in reason. My full Southbend Con OFE with 13" flywheel ran $750 bucks.

-

Rpm Range, And Rear End Gears

Thing is the most torque is typically produced around 1,900 to 2,100 RPM's This is where the efficiency is the highest for towing. For empty running your best be down lower between 1,500 - 1,700 RPM's... With that being said there is little benefit to going above this range. You can run the engine against the governor all day long and not hurt it. (In theory - I personally don't suggest it!) But now the efficiency is going to really low.

-

Need Help Asap With Airdog

Just to toss one on the thread I been talking to a gentleman back east that has lost four AirDog 100 pumps in about one month time. This last one barely travelled 100 miles and losing pressure. Seem AirDog isn't very secure or stable any longer.

-

4 Wheel Drive, No More

Time to do a inspection of the front differential and the CAD unit.

-

Advice On Clutches

I'm running a Southbend Con OFE for a clutch and it holds my current power (+50HP injectors and Edge Comp) and can tow a gross combine weight of at least 17,000 pounds without issues. Check over at DAP he seem to have good prices, also stay to the standard organic clutches and single disc.

-

Air Starter On A 24 Valve

I gotta admit its cool sounding but I'd sure hate to run out of air somewhere. Bicycle pump are you kidding?

-

We're Doomed Gulliver

- We're Doomed Gulliver

Yabbadoo & Dorkweed...- Prowelder Where Art Thou?

I'm not sure.- Pop/miss At Certain Throttle Position

Just thinking outside the box it seems like the timing is advanced and causing the popping. Maybe difference between cam and injection is off? Can you verify your cam timing. Like AH64ID also has a updated cam as well and re-used his cam gear verify it all indexed properly.- Anthill Art

Like this one too...- Ecm Swap Questions

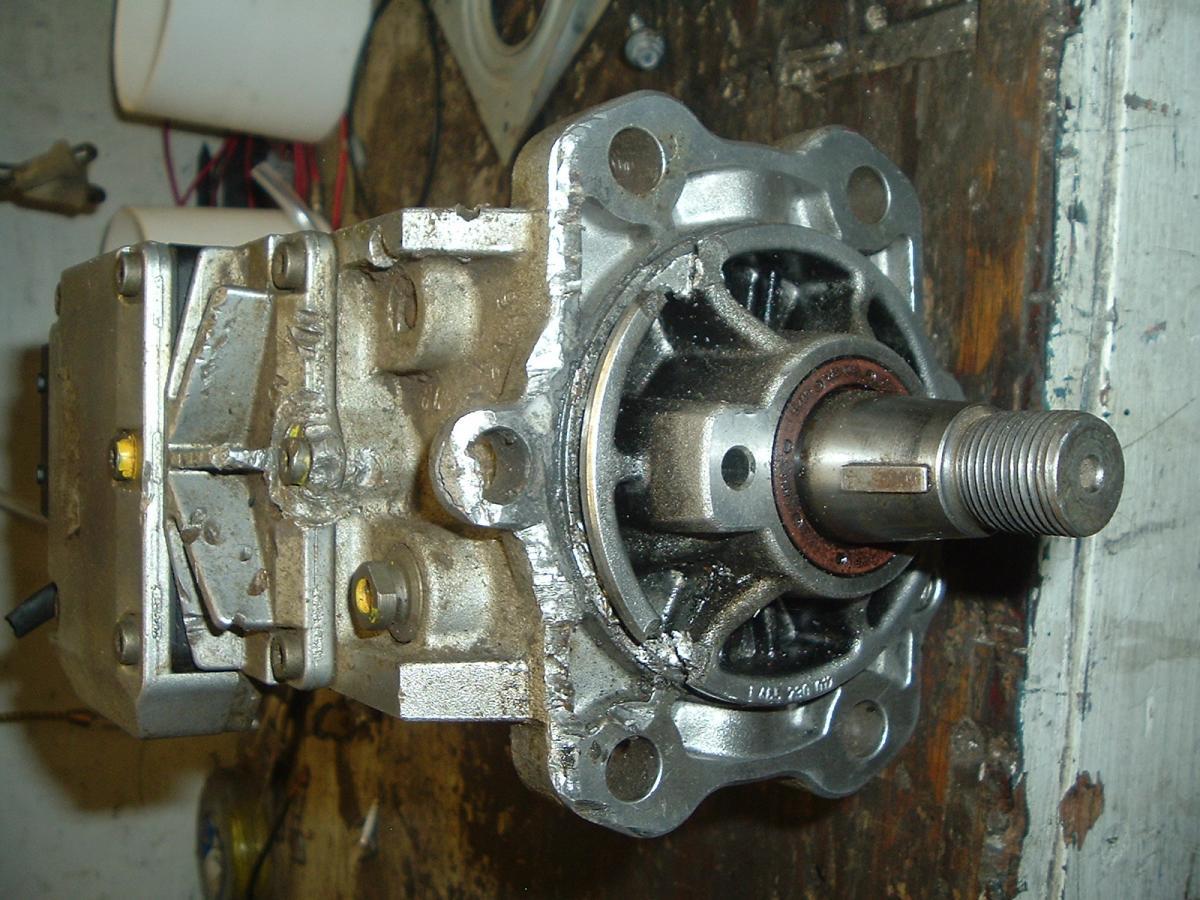

Ground behind the starter is the fuel heater and lift pump not the ECM. Double check AC voltage and be sure before installing the new ECM.- Disassembled A Bosch Vp44 Injection Pump

I wish... To many things are too damaged. The timing piston is so screwed up that you need to use a propane torch to heat up the body of the pump to even move the timing piston. I lost a few springs on the vane pump as they went flying across the shop as I pulled it apart. Then I broke the piston ring on the timing piston messing with it. The body of the pump is all beat to death from the previous owner. - We're Doomed Gulliver