Everything posted by Mopar1973Man

-

headlight upgrade

Even my LEDs in my 1996 Dodge Ram 1500 are great too. The biggest thing that makes a good cut of is a good reflector. Being the 1996 Dodge had a cracked lens and filling with water hence why I replaced my headlight housings. I'll admit the housing I've got are OK but I would not say they are great the pattern is good but too much scattered light personally. Now HID's still win the battle being it covers 5 times as much ground on high beam vs. the LED's. So my 1996 Dodge with LEDs only cover the standard area and not much more. HID in the 2002 Dodge cover way more ditch area on both sides and a total of 50 feet vertical at 1/2 mile. LEDs don't even come close. Now comparing both above with hazed lens and halogen. Still day and night difference. Halogen bulbs are just a mere 860 lumens roughly. The LEDs I got are 2,000 per blub. Then the HID bulbs are 4,000 a bulb.

-

COVID blues

Reman's for 2003 Dodge Ram and 2004 Dodge Ram... New is even more. I need two sets or 12 injectors. Heck even poor @Jthor isn't happy with Ford 7.3L injector prices at $1,200 a set of eight. As for my truck being down I've found a temporary steering box from Russ (my landlord at my other shop). He's willing to let me got snag it. I'm going to go grab it so I can drive my truck again. the 1996 Dodge is eating me out of house and home at 14 MPG. At least with the Cummins I get better MPG's. Soon as the sun comes up I'm gone and going to snag that steering box. I can't wait another 8 to 9 days for my steering box from Blue Top to return in the mail.

-

COVID blues

Yup... Already been warned by the local mail lady, UPS drive and the Local FedEx gal. Going to get worse and slower.

-

COVID blues

Even UPS and FedEx are getting bottle necked here too. Not much better about getting stuf here either. Stuff we pick up off of Amazon like my latex gloves or the alcohol (rubbing 100% medical grade) still like weeks to get stuff in. 7 days to get get my screen protector from California to Idaho from UPS. Heck I could of drove there and back quicker! Only takes me a bit over 18 hours from Home to Mohave Valley, AZ. Makes me wanna fix my truck and go do hotshot work. I can drive like the wind and for long hours easy. Back to reality I need a steering box that is taking a vacation in the postal system regardless if is USPS, UPS or FedEx.

-

Can't get front brakes to fully bleed

Just to do a flush job on my truck I use up to if not more than a half gallon to 3/4 of gallon. The reservoir on my truck holds a full quart just about on its own. If the calipers are empty and compressed back in then you have to fill all the voids again with fluid. If the calipers are compressed in again then the old fluid is forced out and you start filling with new fluid.

-

COVID blues

Man it just isn't getting better. My steering box I mailed out in a Flat Rate USPS box should of taken only 2 days to go from here to North Dakota. Nope! I just called Ryan at Blue Top and verified on the 30th that he got it. It took a total of EIGHT yes! EIGHT DAYS to go from Idaho sit in Seattle WA for nearly 5 days then finally at the last second got to Ryan. Now it going to be another 8 days to get back. I've opted to ask Russ my landlord of the other shop if I could barrow a steering box so I can get my truck to move. That would allow me to start another job needing to do a trans fluid change, filter, governor pressure solenoid, governor pressure sensor, adjust the bands, etc. But I'm not going to lay in the snow and mud to do it. Hell no. I just landed to injector jobs both Common Rail truck both will not start or run any longer. both trucks have over 200k+ miles on the stock injectors. One does start but takes a pretty good hit of ether to fire up. Injectors are leaking so bad it can't make rail pressure any longer. Now I've got to call good ol' DAP and get to sets of injectors coming but in the same token I want the two truck owners to pre-pay for the injectors. I'm not going to pull $5.5k out of my pocket. Then I get the long wait of getting parts from Utah which typically is 2 days to here. I've got return customer the VW Passat needs more goodies as well I gotta find a cam sensor, set of spark plugs, and oil change for that beast. Again call around and see whos got the better price and who can get it here like right now. Not months from now. As for my previous post. The pedal assembly on the 7.3L Ford Powerstroke turn out absolutely stellar. I installed the pedal assembly and was shock how good and tight the pedals feel and the clutch is smooth to operated now. Even the owner that got health issues can easily start his truck and drive it. Zerk fitting to lube the pedal shaft and all bronze bushing not plastic! The company that did this work is Alter Ego Motorcycles down in Arizonia. Super nice gent and he's will to do any machine work for me now. Another one in my phone list for future needs.

-

U0151 - 2008 3500 6.7L DRW G56

What the error is complaining about is there is no communication to that module. That means the CANBus connection is lost and you'll need a wire map and find the pair of wire going to the module and testing to see if the wires are good and seeing signal. It's possible to have a module shorted out and failed too. You might give Module Masters a call in Moscow, Idaho and see if they handle these modules if so maybe they would know the diagnostics for the code. ModuleMaster Electronics manufacturer in Moscow, Idaho Address: 2006 S Main St, Moscow, ID 83843 Phone: (208) 892-0764

-

Can't get front brakes to fully bleed

Is the brake proportioning valve moving the pin in and out with pedal pressure? Is it dividing up pressure properly?

-

No cruise control after engine swap 2002 into 1999

Need to swap back to all the 1999 Electronics to make it work. Fly by wire was later series function. So both the ECM and PCM need to be 2002. More on the swap.

-

Anyone enabled the ecm high idle lately?

I just barrows Bob Wagners personal unit and ran it for a day and mailed it back. Back then I had the Edge Comp and that was too much power for stock clutch. So back the box and sent it back. Still got my high idle enabled yet.

-

Odyssey of the bucking and surging

16.5 to17 is long term idle tap the throttle it will drop to 12.86 typically. This is normal. Being the Quad CanBus is unplugged it something else like VP44 to ECM. CanBus is the data line Quad uses so if it unhooked and screwed up yet the the Quad is not to blame. You gave Vp44 or ECM problem.

-

Can't get front brakes to fully bleed

I've gone from dry to fully load on my truck just using the mayo jar. I've rebuilt my calipers left the lines open drained the system. Now hook up all calipers and bleed. Front are independent from the ABS pump. So if you can squeeze the pedal to the floor you've got air in the system.

-

What I have done/found on Ole Blue today

Agreed. My wheel joint required 100 ton press. Then ballpoint required exploding one before figuring out a trick. Even my shock required 4 foot cheater bar. Nothing comes off easy.

-

*Oil Consumption 5.9 Cummins with 87K-Valvoline Premium Blue Restore Oil*

I wonder if the the valve guides were replaced?

-

Greasing front wheel bearing hub.....

Remember if you get too much metallics in the grease between the tone wheel teeth the the ABS will freak out and set the ABS and BRAKE lights. Not something I willing to suggest. The tone wheel should be kept clean and not filled with grease. Being if the grease has a bunch of metallics then the ABS doesn't count the frequency even and may or will cause ABS issues later on.

-

Odyssey of the bucking and surging

My last Quadzilla failure was similar. I found that my ring terminal for ground was lose and created the same problem you had. I've seen one other vehicle with a bad set of red and red/white wires so the Quadzilla wasn't getting good power. Disconnecting the CANbus just stops the Quad from talking to the ECM and VP44. If it straightens out then look into the wiring more so and double check all the connections. DO NOT hook directly to the battery for either the RED positive or the BLACK ground wires. In the PDC box there is a red wire stud in there to get power. Then hook the black to a the body or engine block it doesn't need to be on the battery at all.

-

Odyssey of the bucking and surging

Disconnect the Quad CANBus connector and see if it goes away if so the Quadzilla is having either power or communication problems.

-

Odyssey of the bucking and surging

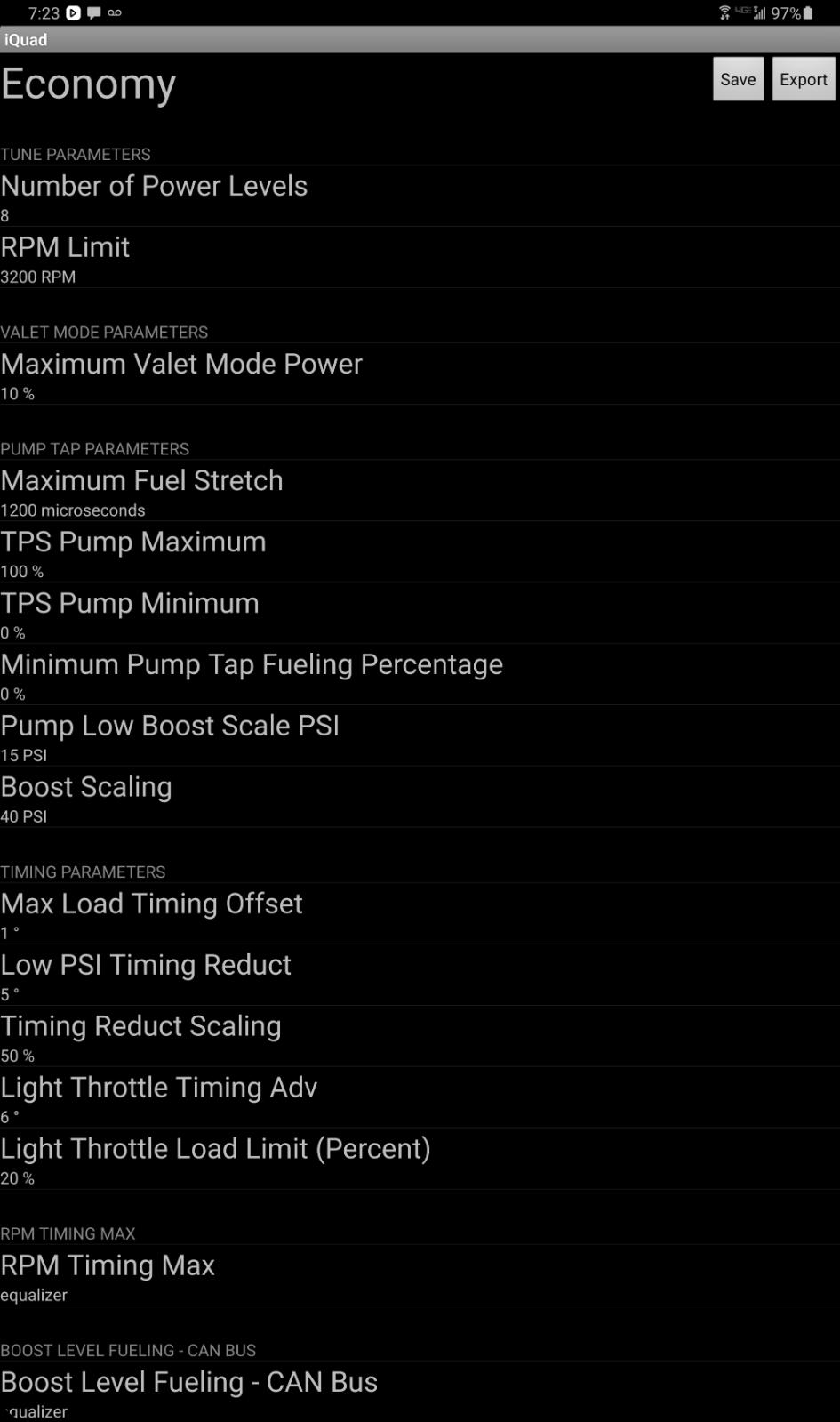

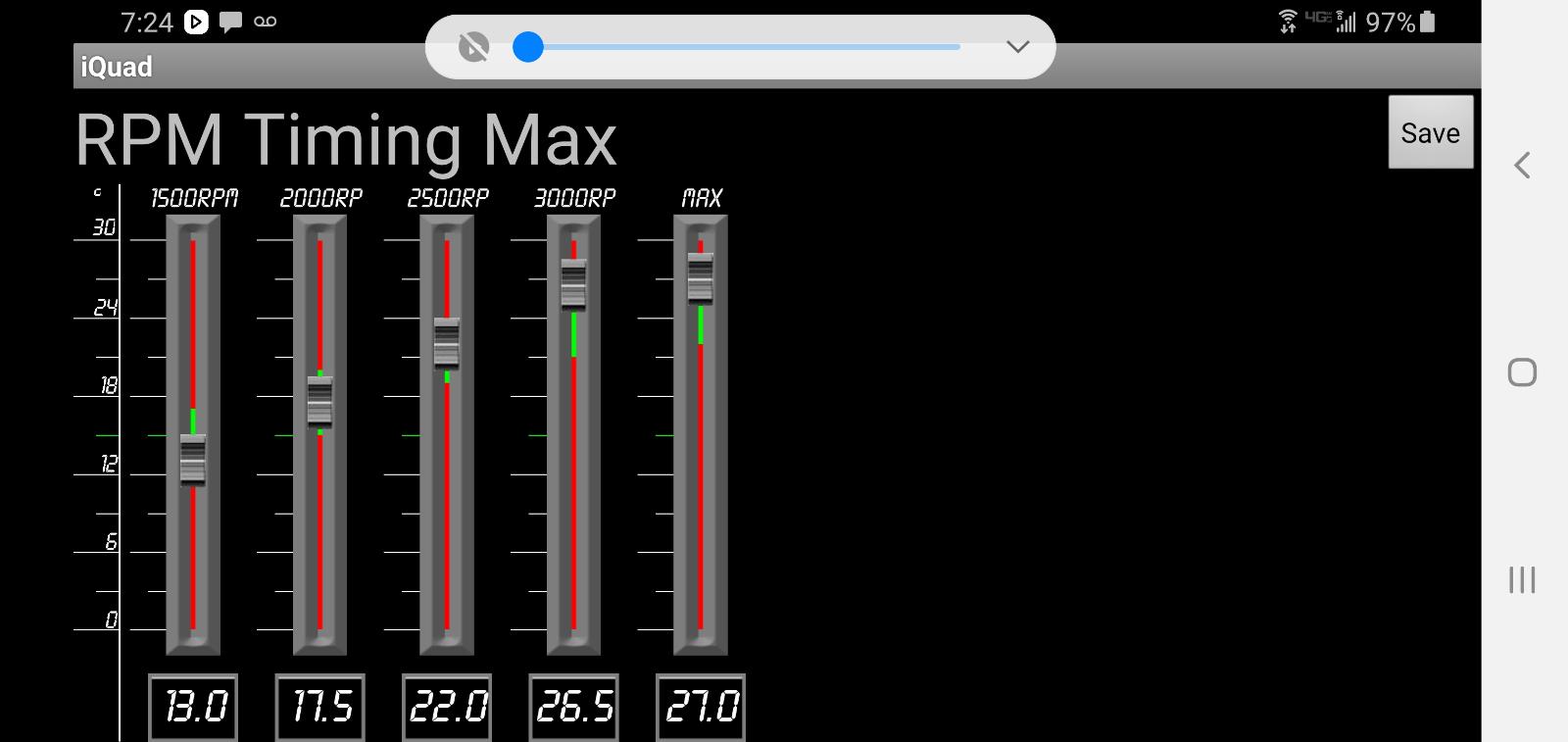

There is no way to see the default tune that is shipped. You'll need to create a tune to make it what you need. Not hard nor long to do. You want roughly, 13° @ 1.5k RPM, 17° @ 2.0k RPM, 21° @ 2.5k RPM, 25° @ 3.0k RPM, 26° MAX for starting. I know this might be too retarded but safer to be retarded than over advanced... Here is what I'm running for my set up. Be aware with the cruise timing high like I run it does buck a bit on low RPM's just drop that to between 2 to 4 degrees on the cruise timing.

-

Odyssey of the bucking and surging

Most likely need to configure your timing for your engine. What is your current timing on the Quadzilla. Pay attention to the RPM and the engine load when your load is low and cruise timing is enabled you could possibly be over advancing the timing. It would help if you uploaded your current tune settings or at least post the Max Timing and the other timing parameters so we can see. Yes bucking is cause by too much timing advance.

-

*Oil Consumption 5.9 Cummins with 87K-Valvoline Premium Blue Restore Oil*

Take notice to the amount of carbon. Like this truck was short tripped a lot and never got up to operational temperature much. Because if you get up over 1,200 EGTs that carbon and oil wouldn't be there.

-

*Oil Consumption 5.9 Cummins with 87K-Valvoline Premium Blue Restore Oil*

Valve guides and valve seal would be my next step. I had done mine back at 350k miles being the vlave guides wore enough to allow the valves to wiggle and then ruin the valve seal that are harden and no longer flexible. Be aware the head will require removal and new head gasket require. Don't just do new seal being the seal will most likely be ruined being the guides might be worn. No way to get around this.

-

Grid heater bypass question.

Being my random travels it makes no sense to plug in. Some days I don't leave home other days I might leave at 8am, 9am, 10am etc. Not to mention im on limited power here being daylight hours are short. If im heading south im warmed up in 5 miles with heat. Go north it will just about take 10 miles. If I want super fast warm up set 3 CYL mode flip on the exhaust brake. EGTs sore to 900 to 1000. I can go from -20F to fully warmed in under 10 minutes.

-

COVID blues

I'm glad I got 9mm back after the last shortage. No warning shot given due to the price of ammo.

-

Hello From Tri-Cities, WA

Just think the stock engine and injectors with turn 235 HP. Now drop in a Quadzilla Adrenaline tuner and that is capable of 180 HP. So for safety sake that would make 355 HP to 415 HP just with tuner. There is a bunch of supporting mods to do to make this happen... AirDog 150 or FASS 150 with 1/2" fuel lines is a requirement. (Currently running a AirDog 150) Automatic transmission will need to be upgraded to hold the power. Manual transmission you need to look at better clutch. (Currently running a Valair Dual Disc) If your running over sized tire, then to get your final ratio correct (3.55 to 3.73 to the ground) Suggest looking at ARP 425 studs for above 400 HP as a safety measure. Possibly look at slightly larger turbo. You can do it on a HX35W but the EGT's might get a wee bit hot. (Currently running HX35/540 Hybrid) 4 inch exhaust. Don't bother with 5 inch your not going above 600 HP. I can go in to detail on any subject you wish.

-

Hello From Tri-Cities, WA

Just to make a serious jump I would suggest just gettng a Quadzilla Adrenaline which is a nice 180 HP jump in power. Fully adjustable tuner that adjust not only thre fuel but also can adjust timing for the VP44 trucks. I'm running 150 HP injectors (7x0.010) popped at 320 bar, with the Quadzilla and my Economy tune I'm right at about 500 HP and 19 to 21 MPG. I got the best of both worlds good economy and more than enough power to light the tires up on dry asphalt. Just to give you a feel... As for all the mod check my sig for my modification list and there is 4 pages worth.