Everything posted by Mopar1973Man

-

Dead pedal

As for the high idle switch jump over to the support ticket. Which I'm going to bet the P0113 is from. https://mopar1973man.com/support/

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

No. It's safe I've already talked to Michael Pliska at ISSPro. A toggle switch is fine to use. Yes way too high. Transmission and differential temperatures can run pretty high. Like my gauge is 100 to 280 transmission temp gauge.

-

Smoke/vapor from vent tube.

It can vary from day to day. Some of that is moisture your seeing. As long as you not using oil or blow oil out of the truck your fine. If your concerned pull the injectors and do a compression test. Like one member found out that a single cracked piston can pass a blow by test but would fail a compression test. So as long as your truck doesn't look like this I think you are safe.

-

Egt’s

Like I'm running a HX35/40 Hybrid. Its a 60/60/12 in measurements. I hit 45 to 47 PSI of boost on WOT. Regardless, the actual EGT's while cruising 65 MPH is like 550°F and barely 2 PSI of boost. The main factor in MPG numbers is working your timing higher, then watching the engine load sink. The biggest problem you won't lose is the frontal area with the lift kit and the standing height, the only way to reduce that drag is to drive much slower. All speeds above 55 MPH are exponential for wind drag. Roughly speaking for every 10 MPH above the wind drag doubles exponentially. Hint I know my 55 MPH speeds will net me close to 24 to 26 MPG. Too tough to do with my time schedules.

-

Egt’s

High boost typically mean lower EGTs. The only way EGTs rise is engine load rises, timing is retarded, or drag is increased. Boost should be left set at 30 to 35 PSI.

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

-

Mechanical lift pump

I cleared over 250k miles on my first AirDog 150. Second replacement 3G pump lasted barely 15k miles. Third, now got a 4G pump and the AirDog is rock solid again. I would consider a mechanical pump only if the pump can with a prefilter and 3um main filter like an AirDog. Then keep an electric priming pump. So many times I have seen old mechanical 1st Gens and 2nd Gen with broken primer. Nearly insane to get started again without the primer pump.

-

Egt’s

Seriously doubt the boost is the problem most people are looking for more boost to keeping the EGT's down. The only measurement he doesn't have is the engine load before and after. Engine load equals EGT's.

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

Yup...

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

Kind of like a VW yanking a tree stump eh?

-

Egt’s

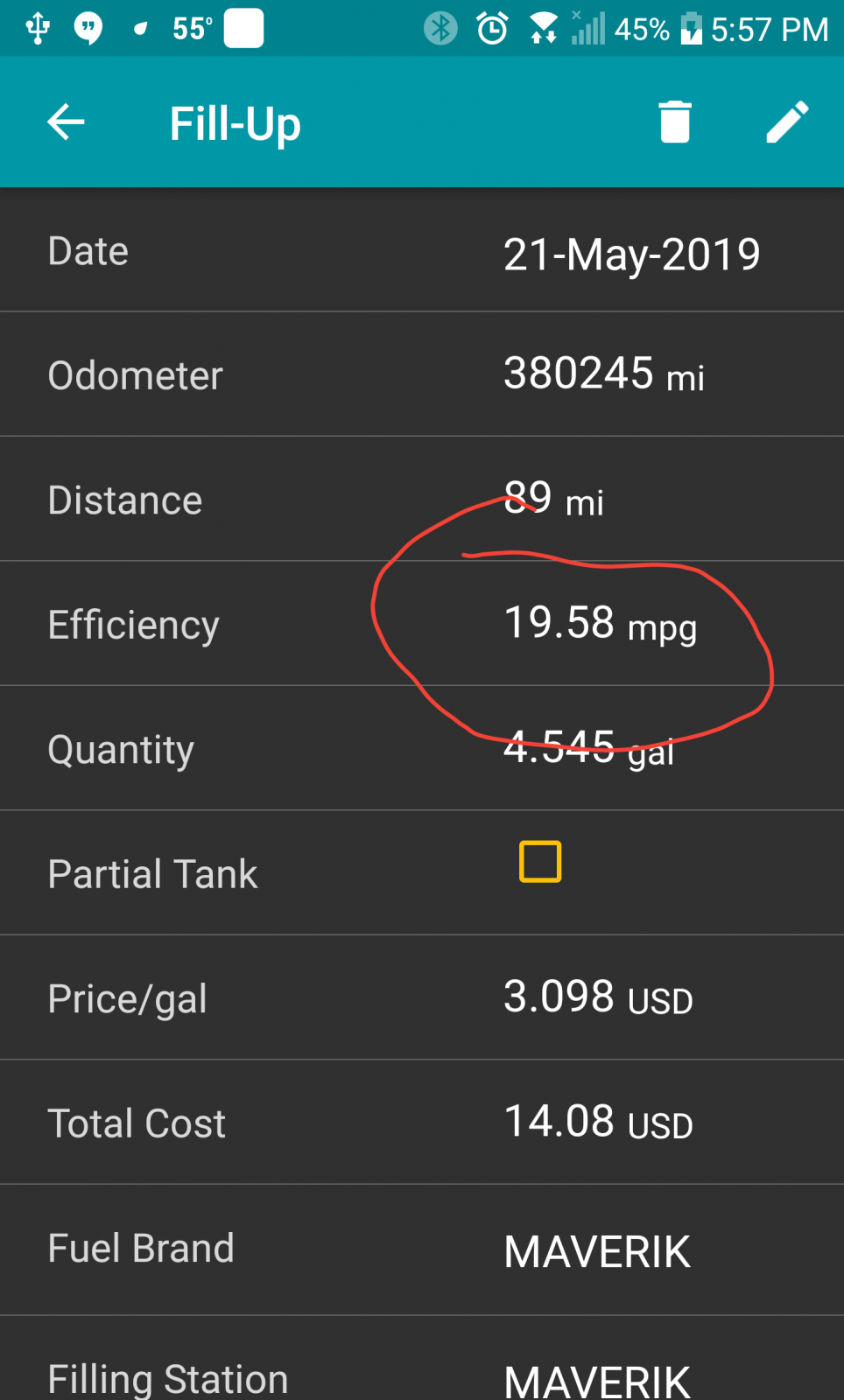

No, It will gain you MPG for sure. Like me, I'm twisting 2,500 RPM at 82 MPH but still kicking out 19.58 MPG. My last 3 years of fuel logs. You can see my Economy tune is also a big gain. 3.69:1 final ratio to the pavement.

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

Not really. The top two gears are the same. Is just there is an extra gear in the bottom. Just consider the thought my current setup (NV4500 and 245's) I'm in 4th gear at 25 MPH. NV4500 - 5th gear - 0.75 NV6500 - 6th gear - 0.73 NV4500 - 4th gear - Direct NV5600 - 5th gear - Direct

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

-

Mechanical lift pump

Little birdie told me Assassin is China Made now.

-

Egt’s

Excessive wind drag and excessive low final ratio which I calculate 3.39:1 to the ground. You need to change your gears to 4.10 at least to fix this problem. Wind drag will ever go away with the lift. Bigger exhaust isn't going to fix the problem. 4" is plenty big enough which it will take care of 600 HP easy.

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

If you have 3.55 gears... Now for towing if you want a killer setup, drop the stock 265/75 R16 tires and switch out for the 245/75/ R16 you'll find you have way more torque and cooler EGT's. Then the exhaust brake works even better with the 245's vs the 265's.

-

Towing...Your Experience Is Appreciated 98.5 24V 2500

VERY IMPORTANT!

-

2000 3500 no power,sucks fuel like it's free

That sucks...

-

No Start... Please Help!!!

- Best Place To get a new ECM

I would love to build and sell a VP44 test lead for that purpose with a toggle switch for power and protection fuse.- Quadzilla V2 reading inconsistent boost under load on 1999 24V.

Here is our list...- Towing...Your Experience Is Appreciated 98.5 24V 2500

Lots of options for exhaust brakes. If mine dies this is the exhaust brake I'll buy next. https://pacbrake.com/product-lines/exhaust-brakes/- 2000 3500 no power,sucks fuel like it's free

Not really. 12 MPG is something you should see towing 8,000 pound trailer.- Egt’s

You should be able to monitor engine load as your traveling. Max number doesn't mean much. I need to know your tire size most likely your final ratio is too low and the engine is struggling excessively. Final ratio to the pavement should be in the 3.55 to 3.73 optimally.- Egt’s

Extremely high. I barely float 700°F with the Quadzilla on Level 7 (full wire tap). I'm running 82 MPH at 2,500 RPM and still after nearly 100 miles of this netted 19.58 MPG. Engine load just barely below 25% which is my cruise limit and floating 26.89° of timing at 2,500 RPM cruise timing. What is your engine load like at 80 MPH? What size tires are you running? What gear ratio is in the rear axle? - Best Place To get a new ECM