Everything posted by Mopar1973Man

-

Verifying HX35/40 turbo size

Since CSM gave me the turbo I figured since I needed new injectors I called Jacob @ Diesel Auto Power and talked him about injector replacement and bearing kit. Talking to him we figured we would give the +75HP a go with the HX35/40 turbo. Being I came from +50 HP injectors small boost in power but also adding the turbo. Then with the fuel management of the Quadzilla I should be able to create good clean power. We will see.

-

100hp 7x.009 injectors EXHAUST POP?

Carb dip is the best so far. Coleman fuel works good. Even carb spray (using the red straw) works good for blowing the nozzle out.

-

100hp 7x.009 injectors EXHAUST POP?

Spray issues? Lack of boost?

-

100hp 7x.009 injectors EXHAUST POP?

Build up? Sounds like ash deposits but hard to tell. Shot some pictures.

-

Towing Help (Concerns)

No typically they do not. Fuel pressure might take a bit of creating. Boost do not get the boost bolt. Just use the pipe plug in the side of the block. Way too many time that boost line gets broke off or the boost bolt snap in the manifold being hollow and attampting to tighten enough to prevent boost leaks. Trans temp again your going to have to get creative and EGT does come with the probe and everything but you have to drill and tap the manifold. Standard OE rotors and economy brake pads. The economy pads won't eat your rotors then at tend to last longer. So your choice is ditch the tires or re-gear the axles. Most that look at prices of regearing typically get shell shocked like a local gent at $4,000 for both axles and change from 3.55 to 4.11 or 4.56 for his 37" tires. Just like him he's struggling to tow anything because his final ration is 3.00:1. Towing optimal ratio for these trucks is 3.73:1 gears. Either way you need to bring your ratio back to reduce the stress on the transmission and engine. Also remember the 47RE atuo's have a final ratio of 0.68 compared to manuals of 0.75 (5 speed) or 0.73 (6 speed) ratios. Now OD OFF is the same as on gear down on manuals (1:1 direct drive).

-

Verifying HX35/40 turbo size

Naw... +75 injectors and HX35/40 turbo power bug? I don't think so. I've already got enough power to get in trouble and break expensive parts like transmissions with my previous setup. Come on brown truck get here... I need my parts. The injectors are all pulled out and head is ready for injectors. The turbo is tore down and ready to be rebuilt.

-

Fuel sumps are illgeal

@jokra could you post the link to the information...

-

Verifying HX35/40 turbo size

I got a turbo from @CSM and I went ahead and got it pulled down to rebuild it. While its apart I figure I would measure out the turbine and compressor wheels. Here is what I got. Compressor Inducer 60mm Exducer 83mm Turbine Exducer 60mm Inducer 69mm From what I found online this is a HX40 compressor wheel. The HX35W is 56mm compressor wheel. So this should be a rather nice boost (pun intended). Waiting for my bearing kit to come.

-

100hp 7x.009 injectors EXHAUST POP?

Time to re-do the install of your injectors you most likely have a high pressure leak inside the return rail or possibly push debris into the injectors which would require pull them apart one at a time and checking.

-

Summer refresh thread

That's what I've got in my axle now and still tight. AC Delco ball joints.

-

Summer refresh thread

@jlbayes If you lived near me I'd be more than happy to change that heater core so it does melt your face off.

-

100hp 7x.009 injectors EXHAUST POP?

Just upload the video to youtube and then copy the URL back here. It will automatically post for you.

-

100hp 7x.009 injectors EXHAUST POP?

What you want is the injector lose so it floats in its hole so when you tighten the crossover tube lightly the crossover tube can self-center the injector to the crossover tube. Basically, you need to almost do the install all over again and tighten the crossover tubes first not super tight but enough to ensure the tube is firmly seated before clamping the injector preventing from rotating.

-

Quadzilla app and opinions on it

That might be true but you have more communication with Spencer than I do so you'd still know more than I would.

-

Towing Help (Concerns)

Who me?

-

Towing Help (Concerns)

Here you go... https://mopar1973man.com/settings/signature/

-

Towing Help (Concerns)

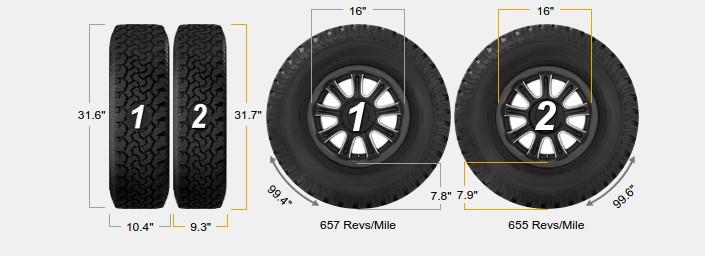

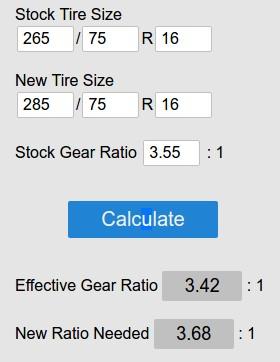

First off dry weight is meaningless. Like my RV dry weight is 6,800 pounds. Actual scale weight is a worlds different. As you see it much heavier than dry weight so just forget that number and go find a scale. Tires are killing your power ditch the 285's to gain back your gearing. So you 3.55 gear ratio is now 3.42 which is making the truck work harder. I'm going to bet your EGT's were through the roof even for a stock truck. I highly suggest you get boost, pyrometer, fuel pressure and transmission temperature gauge. Very important to monitor these while towing. If you ditch the 285's tires you won't need the 3rd gen calipers. I'm running 235's and exhaust brake my brakes are going to clear 200k miles. My first set of brakes lasted till 185k miles. I travel the mountains of Idaho with grades up to 16%. Again tire size makes a huge difference. Again... Tires. The tires your running has altered the final gear ratio so it like driving a gear higher all the time. I ran for years just stock injectors and Edge Comp. Over the years I've been upgrading now hopping up to +75 HP injectors with the Quadzilla. Even with my +50HP and the Quadzilla I was able to get the rear tire to light up towing trailers. Even this trailer full of 10,000 pounds of hay... Here is stock 265's compared to 235's. Basically 1.1" narrower 1mm taller but I'm 23-25 pounds lighter on the axle. Rotational mass reduction! Now your setup... 265's vs 285's. Gear ratio has been altered. So now the leverage force to stop the truck have been weakened because for the wheels size giving more leverage against the brakes. Then since the tires are large they are heavier (more rotational mass) and more strain on the transmission. Basically the heavier the flywheels (wheels & tires) the more difficult it is to stop them.

-

ABS failure found!

@Chris O. could you produce a list of what all the ID### are? Not yet... I've got the injectors coming tomorrow and be getting that done first then I can get to the logging functions very soon afterwards.

-

Mopar73 Full Eclipse Meet and Greet Camp Trip Aug 18th Thru the 21st 2017

Dark lens for viewing the eclipse... Welding lens can be pretty dark tint.

-

Quadzilla Adrenaline Economy and MPG

Also, keep in mind I was fighting the failing injectors that were most likely popping early and low pop pressures so timing was wild on my end. So now with my new injectors I can finally build a tune that I'll most likely leave alone. SAC Because now with the Quadzilla you have a way better control of larger injectors. Look at @Me78569 and @TFaoro both with larger injectors and smokefree tuning. Now is it possible to get high MPG's with my setup? Don't know but... Brown truck is coming tomorrow with a turbo bearing kit and a set of 7x0.008 SAC Injectors. (Opps its suppose to be 7x0.0085 injectors...) https://dieselautopower.com/diesel-auto-power-75hp-performance-injectors-7x0-0085-sac-vp7x85sac75/ https://dieselautopower.com/holset-genuine-hx35-rebuild-kit-3575169/

-

100hp 7x.009 injectors EXHAUST POP?

Did you tighten the injector hold down first or the cross over tube first? If you did the hold down first then it could produce a high pressure leak between the injector to cross over tube and leak into the return rail which you'll never see.

-

Mopar73 Full Eclipse Meet and Greet Camp Trip Aug 18th Thru the 21st 2017

I might just grab my welder hood to bring along.

-

Quadzilla Adrenaline Economy and MPG

No. I'm still running a stock SO pump. Basically, they would be +75HP injectors but with the pintle mods that are done, it should flow like a +90HP injector. I still think the Quadzilla is well worth it yet. Comparing Edge to Quadzilla price per HP its still way cheaper. The fact that timing variable is now open for use to tune against is very difficult since we can't see what Edge has for timing curve and what not. I can see what stock timing is like but its a question of how much timing and when (RPM wise). That being said the injectors size also is the other factor smaller injectors tend to like less timing where larger injectors like more timing.

-

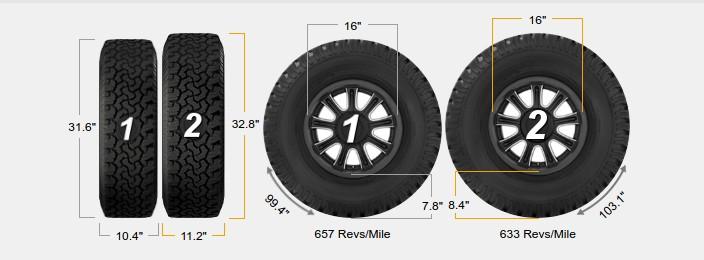

Quadzilla Adrenaline Economy and MPG

True I was seeing better MPG's on Edge Comp but that is during the summer with summer fuel. I started this adventure as winter fuel started, winter conditions, with beta testing software that has bugs. Yes, Edge Comp would be a more solid MPG number. Tuning wise Quadzilla still hands down the cleanest tuner out there. Edge Comp is very smoky compared to Quadzilla. With my new 7x0.008 injectors coming Edge Comp won't work for me any longer because of lack of boost to fuel control. Basically you only have 1-3 defuel levels. You basically lose the Edge Comps abilities if you below the boost level set. EDGE COMP SUBLEVELS 1. 33% of fuel till 20 PSI of boost. 2. 50% of fuel till 15 PSI of boost. 3. 67% of fuel till 10 PSI of boost. Now look at the Quadzilla tune. I've got full control of the fuel map compared to Edge Comp and this tune is still smokeless. You can't even come close to a clean tune with the Edge Comp or Edge Juice because the adjustment of fule to boost is way too crude. Then Timing there isn't any control of timing. Now you also have to consider I started down this road with injectors starting to fail. This also made a impact in my MPG's. Then now being kicked back to stock injectors knocked even another full -1 MPG my logs I've seen. I'm really curious when summer fuel, summer weather, etc all come back. I've seen a few day where my IAT was in the 100-140*F and MPG's started climbing for that part of the day then storm would roll in and the IAT would fall back down and so would the MPG numbers. I mention timing above... That another factor that no other programmer has given is full control and abilities to see timing and control it the way you want. Edge products have there own software which is fixed. That might be great for stock trucks but how about modified with VP44 hot rod pump? Won't work because the Hot Rod pumps have timing advancement and shouldn't be used with a Edge Products.

-

Help 47re won't shift out of 1st

Just the throttle valve cable that all. There is no vacuum per say to the transmission maybe to the transfer case for CAD unit but that's it.