Everything posted by Mopar1973Man

-

iding too high

Idle Validation Switch or IVS. Pins 6, 2, and 1. Typically on a stock APPS the voltage with toggle these two switches. On a Timbo APPS the sensor angle is what toggle these two switches. Basically Pin 6 is grounded to Pin 1 if in IDLE position or Pin 2 is grounded to pin 1 if THROTTLING. Never are both open at the same time nor are they both ground at the same time. So if for some reason the IVS is tripped to THROTTLING it will follow the voltage as a idle which is wrong and typically causes the engine idle faster than normal. So once the IVS is flipped to IDLE position now the APPS sensor voltage is ignored and the ECM software takes over for idle speed and should land right at about 800-850 RPM typically.

-

Camper vs trailer

Like for us an RV is a valuable tool. Since we live so far from a large cities it allows us to pull the RV down to RV park and be just outside the large cities and be able to gather supplies, groceries, etc. Either way we go there is at least 5-6 hours of driving to making day trips to larger cities. So this allows us to doing shopping without being rushed. As for camping we are already making plans for this summer on where we would like to go. I will admit the 5th wheel you got Hex0rz is huge and I would have to say most likely too big for your truck anyways. I would sell it for now like Wild & Free is suggesting. Then later on when thing settle down again or maybe get lucky and find something a bit more suitable for your truck and camping then go for it. I would weight your options of slide in camper, travel trailer or 5th wheel again. Next time when you plan on getting back into an RV I would weight out you truck and see what you have left over for towing / hauling.

-

Blowing Headlight Bullbs

Did you touch the glass on the bulbs? This will create a hot spot and cause the bulbs to fail premature. Where did you hook the ground? Where did you hook the positive lead?

-

Camper vs trailer

Hex0rz travel trailers are much lower hitch weight mine is about 1,100 pound much more manageable vs heavy pin weight of your toy hauler. I tend to agree with Wild & Free the optimal is to get rid the toy hauler. If you opt for a RV again I would suggest a travel trailer way less hitch weight and typically lighter trailer weights vs. most 5th wheels. Still have a fair sized RV without lot of weight on the truck. Like JAG1 has quite a heavy camper for what he's got. I'm sure Me78569 camper is lighter but he's short the bathroom and holding tanks (he's got water). Again you back to a lot of weight on the truck. Again Wild and Free is right and would bee best to get rid of it and put your money into paying off your current house.

-

iding too high

Actual programmed idle speed should be 800-850 RPM. 700-750 RPM is too low and not normal. The only thing I can thing off your IVS switch is still on throttling position which would cause it to ignore idle software causing a higher idle RPM.

-

Pyrometers install

This is what I love about the EV2's... No replaceable bulbs but you can program the gauge for your level brightness, warning light level, needle reaction speed, and even install a addon programmable relay.

-

Advice on RV trailer fender

Very nicely done. Looks good.

-

Diesel repair 2nd gen Vancouver,wash

Good question what does need to be done? Maybe we can help you get it done?

-

Aftermarket AAPS??

LOL... Right... $230 bucks a bit steep. Wow! $70 more than a Timbo's. This will wait for quit a while... My pockets aren't deep.

-

Aftermarket AAPS??

No argument out of me... It not the point of Wells design... It the foolish people the world that will attempt to adjust it to the tag value of the old OE APPS. The whole fact we are back to adjusting voltage is going to get a lot of people in trouble. So as the Wells APPS get more popular I'm sure there is going to plenty of people starting to complain about lack of exhaust brake function or higher curb idle RPM's (but not high idle). The fact of the matter is the value on the old APPS is meaningless but I'm sure lots of people will attempt to use it thinking that is the calibration of the ECM which isn't right. I like the magnet design (from what I've seen now). I just not fond of the voltage adjustment part. I remember back when CF create the voltage adjustment thread. http://www.cumminsforum.com/forum/98-5-02-maintenance/13542-apps-adjustment.html This thread created all kinds of issues with curb idle, high idle functions, exhaust brake functions, etc. Then in the thread about measuring the voltage at the PCM. Then made the issue worse. What I see is people going in all different directions with this Wells APPS voltage adjustment again. That why I came out with... So eventually I'll have to buy a Wells to just play with it and get a article wrote before people get in trouble. Only problem I can't get one locally I've got to drive to Ontario, OR or Lewiston, ID to get one.

-

Wood Burners

I lit a fire last night as I watched the temps fall down to 41*F knowing MoparMom like to stay warm. Got this morning to her complaining to me that I got it too hot for her last night. I've got 1.5 cords left burning season is coming to close really soon. I started with 9 cords.

-

Aftermarket AAPS??

That why I love the Timbo's vs OE there is no voltage to set. Now Wells and OE APPS are voltage based and will have to set below the throttle trigger point. Good it doesn't wear bad it voltage based again. I already see people getting wind of this and attempting to match the old tag value again that is wrong for both OE and Wells. It should be below the trigger voltage.

-

Aftermarket AAPS??

This is something I'm not liking about Wells... That fact here we are back to palying with setting voltages for IVS switch operation. Again going to get all kind of people screwed up about using the old OE APPS voltage tag numbers and no understanding the IVS function. Here is the best homebrew design I know of. http://www.cumminsforum.com/forum/98-5-02-powertrain/54322-anatomy-apps-sequel.html#post536826 Again yeah electronics make the package smaller...

-

Aftermarket AAPS??

Ok. That explains it... I've been hunting for the info on this... I've see reference to this before but never been able to find the video again. Thanks... TFaoro. I still got my doubts on it. Still relying on electronic transducer. To toggle IVS and produce voltage range. Might not have rheostat but still electronics... Time will tell. I graciously admit my lack of knowledge on the magnetic but still time will tell. Wonder how it does with high AC noise issues over time?

-

Boost fooler

What is happening is when you flash a tune into the ECM, the ECM has checksum number to validate the code. So at key on (boot up) the ECM loads up all the information and verifies the code against a checksum. Since you've modified the code with a Smarty the checksum doesn't match so... POOF! P0602 code is tossed. The only way to get rid of this code is return to stock and hook up a wired module like Edge or Quadzilla. Yes it's normal for all programmers to toss the P0602 code. If the give away clue to a dealer that you messed with the ECM that's all.

-

Aftermarket AAPS??

No matter what that W (Wiper) has to have contact with the resistance material. Other than that the ECM would be screaming about P codes for the APPS sensor. So as for the magnetic function the best I can thing of is using magnetics to pull the wiper around hoping to reduct contact pressure and wear of the resistance material. So the whole thing about nothing to wear out I highly doubt. Once again the wiper must stay in contact of the resistance material just like your fuel sender for your gauge when the wiper breaks the circuit you end up with a P0460 code. So in the above picture consider A hooked pin 5, W hooked to pin 3, and B hooked to pin 4. The only thing missing is IVS. So in a nutshell dead pedal is when the APPS sensor goes out of range and the ECM ignores the APPS sensor out of safety to keep from having possible runaway condition. So as soon as the voltage of the APPS goes hi or lo the code is tripped instantly and the ECM drops the fueling to IDLE out of safety hence the dead pedal. I know the Stock APPS relies on voltage to control the IVS switches and Timbo APPS controls the IVS by bellcrank angle. As for the Magnetic APPS I'm going to assume the same mechanical IVS setup but the rheostat is still a rheostat.

-

Front Crank Seal Help .... and show and tell of what the dealer did

Since you've got a speedy sleeve and its fresh, depth isn't too much of a problem. The depth part is to change placement so you not riding on a old groove. So you could do flush or slightly inset. I still say install from the front.

-

Wood Burners

As for me I'm still burning wood. Night time temps still fall to near 35*F at night even though daytime highs are in the mid 70's like today.

-

What happens if you don't do an apps reset?

-

What happens if you don't do an apps reset?

Either will work.

-

What happens if you don't do an apps reset?

Watch this video...

-

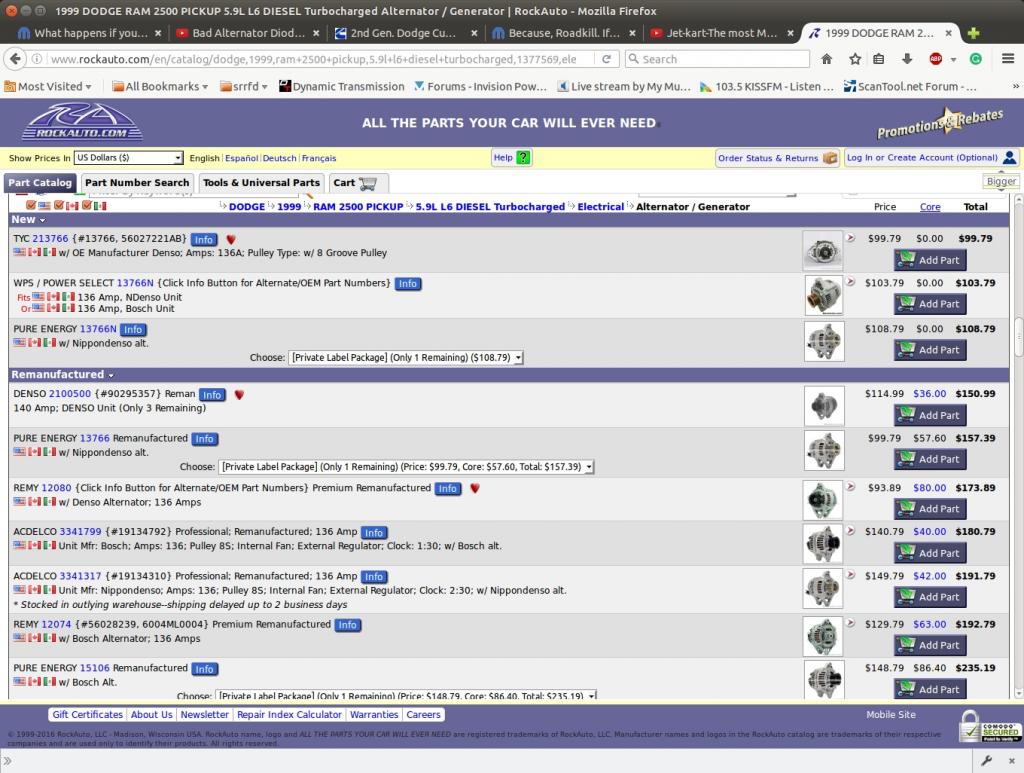

What happens if you don't do an apps reset?

FAIL... Anything over 0.1 AC volts is a fail... 0.010 to 0.030 Normal good alternator working normally. 0.050 Marginal. Some issue are reported typically and random in nature comes and goes... 0.100 FAILED. Diodes are shot and allowing too much AC voltage through. Beyond the 0.1 and up you start to see electronics failures like ECM, PCM, or VP44 more commonly.

-

Wood Burners

Ok. Another one that happen this winter. I do my nightly stoking of the fire and cut it back really low. I got up in the middle of the night to the smell of smoke in the house. Run down stairs to the stove the smell isn't there. Come back up stairs you can smell the smoke. What was happening we had a wind event in the canyon that was rolled the smoke down on the north side of the building and blowing in around the little bit of a gap under the door. So at 2-3am its a bit spooky to go back to bed smelling smoke in the house. It might not be a chimney issue but could be wind driven back into the building through cracks or gaps.

-

Aftermarket AAPS??

Timbo APPS are not lifetime. Not that I know of. Typically most just release the throttle and wait a few second and go right back to working. Basically if the rheostat wears and the voltage goes out of range the ECM ignores the signal hence the dead pedal and once the signal is normal again then the throttle works again. So if your having this issue then its time to resolve it. I'm the same way. I'm always at least hundred miles from anywhere and without cell service. I've got my old stocker in the shop but I don't carry any parts in the truck. I don't go into panic mode and ton of spare parts and tools in the truck. I can say in 261k miles I've never been left stranded or had to tow 2002 Dodge home. Now the 1996 Dodge did eat a PCM and required a tow. Things like this do happen. Like I've got a bail out bag behind my seat. Truck dies I attempt to figure out if I can repair if not the grab the bail out bag and do the "Heel Toe Express" to safety or help.

-

Wood Burners

Been here for 25 years and heating solely on wood heat. No propane, nature gas, or electric heat in the houses. Even this amount of smoke doesn't bother me...