Everything posted by Mopar1973Man

-

VP44 Injection Pump Teardown - How it Works

I can say without a doubt I found a gent that has managed in increasing the VP44 volume and capacity. We've been talking for a awhile and made a beta test pump. I can't remember the volume per stroke but it's got more than a dragon fire pump.

-

Daily tune help

DAP 150HP VCO Injectors (popped at 320 bar) have been my cleanest and coolest injectors with good power.

-

Vp44 psg removal

All can be removed. Fuel solenoid is 3 screw. Then the plug will be released from the solenoid. Timing solenoid can be removed. Remove the screw and pull the solenoid valve out of the body. Fuel temp and tach signal can be removed. Two screws and carefully remove the sensor.

-

Head studs

The reason I didn't totally bottom out was after about 150k miles of them in the block some were rather tough to break lose and get them to spin out.

-

Daily tune help

Being the final ratio is low yeah it needs retard to get the turbo spooled. If he had 3.60 to 3.73 then he could start with 15 @ 1500 RPM. But low final ratio needs heavy retard to spool. But even with good final ratio 15 @ 1500 will make a manual buck at low RPMs just to be aware.

-

Fuel in Oil

Compression test would be good step. What was the injectors popped to what pressure (bar)?

-

Mishimoto trans cooler

Or program your ISSPro for the optional relay to turn on and off the fan. Most forget ISSPro EV2 are USB programmable.

-

Truck stuck in 3rd gear limp mode

Dynamic Transmission is the vendor for automatic transmissions. You could talk to him about what you need done. @Dynamic

-

Mishimoto trans cooler

Sorry I'm all manual transmissions. Even my 1996 with Dynamic trans rebuild rare to see above 160F.

-

Last job I'll ever need...

Just in the work I've done in prepping for this is unreal. I've been lucky to have one day off through the week. My tool boxes were cheap for $200 a pair. There wasn't any keys for the locks. I got lucky with the locks being they had the code on the lock and George Lock and Key in Lewiston was able to make a set of keys for $15. I've been shopping locally for tool deals to outfit the shop truck. I've got basic tools for now but I need to expand that so I'm not running for the tool box at home to make up the slack.

-

Head studs

Reason why. When I pulled the studs out the long studs on the outside of the valve cover has some rust started and I had to clean the holes out and clean the threads. I lubed the threads on the block end to retard rusting in the future. First install I did it dry and wishing now I didn't. The other thing I bought a 10oz bottle of ARP lube for install instead of the little tiny 1.5 blister pack. This way I could really put as much lube on everything as I wished.

-

Last job I'll ever need...

Exactly... I've been there before worked for people I didn't get along with and the conditions were good but not great. I'm getting older and don't want the laying in the dirt and limited shop. Done plenty of that I'm not wanting to do it anymore.

-

VP44 Injection Pump Teardown - How it Works

If you Idaho like I am there is no bio-diesel available. Now if I travel 125 miles I can get B5 in Oregon at a much steeper price.

-

Last job I'll ever need...

Let me get started and see what happens. I might not like the conditions or work who knows this is why I'm keeping an open mind. I've been hired by many people and some cases I don't like condition or time restrictions.

-

Head studs

I left about 1/2 turn out but after torquing to 125 foot pounds I'm pretty sure they bottomed out. I lubed both ends...

-

Last job I'll ever need...

My last week of clean up. Then I switch over. I've got toolboxes and tools on Thor even got new keys for the locks. Then having my 2002 running again is super nice.

-

VP44 Injection Pump Teardown - How it Works

Just remember the diaphragm is not rubber like early versions. The current version uses a steel disc.

-

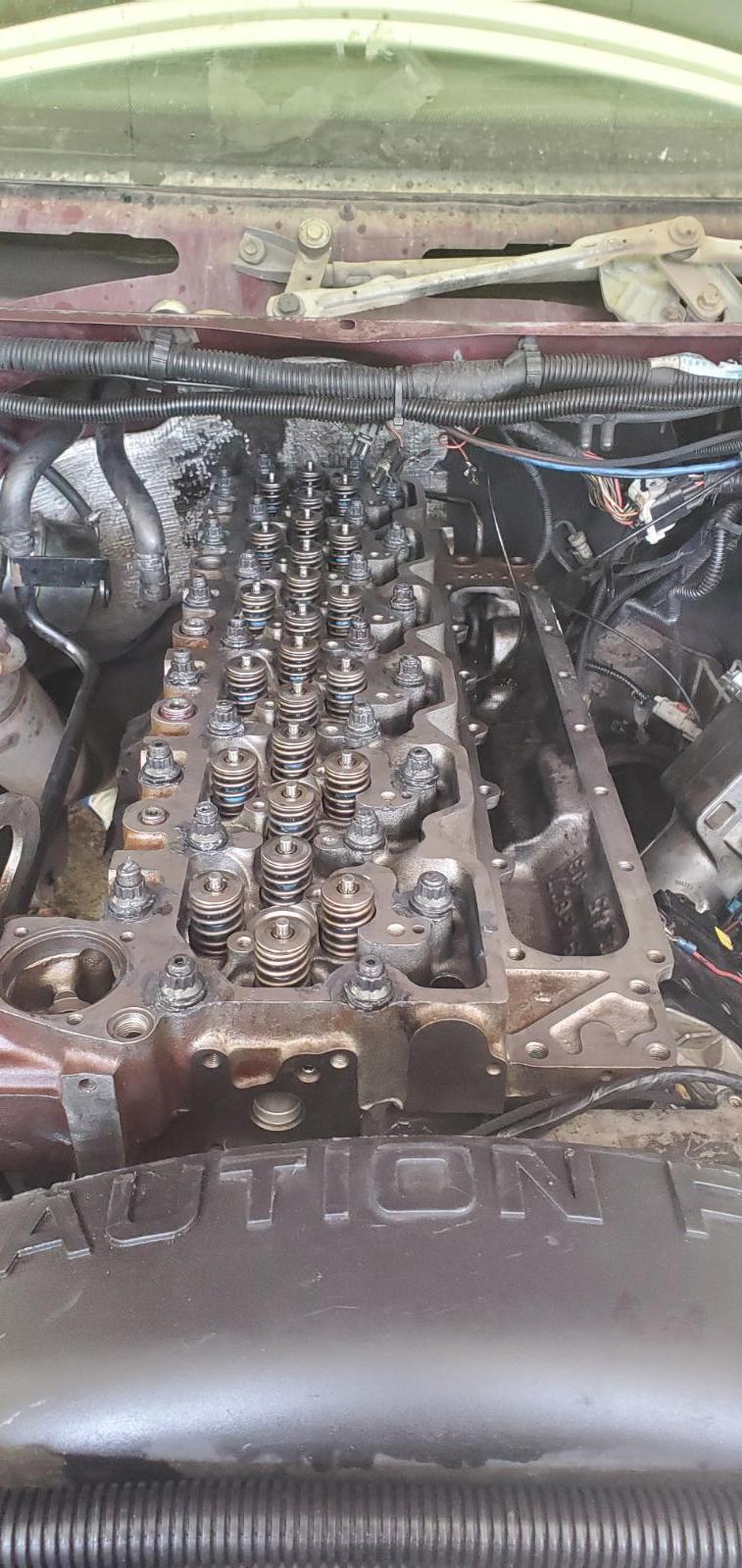

2002 Dodge - Head time.

-

The Future of Trucks

Taxes should be based on the kilowatts used and road miles driven personally. That way the kilowatts are paid for and the road taxes to maintain roads.

-

Intermittent hard brake pedal

If the return was plugged I would figure it would apply the brakes being it can't release pressure. I still think spool valve being its not applying pressure to assist with braking. Maybe the pump but steering would be affected being heavy. Could be the inlet is plugged but I would figure steering again would be affect being its daisy chained to the steering.

-

The Future of Trucks

Still ask who is paying for the power?

-

Intermittent hard brake pedal

Only thing I can think of is the spool valve has an issue. You can get a Pirate Jack rebuild kit and rebuild the hydro booster. Then you can see what's going on.

-

The Future of Trucks

Good point...

-

2002 Dodge - Head time.

Just did a search you might verify the posted size against one of your old nuts. Ive found 12mm x 1.75 but no 12mm x 1.50... verify the size.

-

Blown Head

Any updates on this?