Everything posted by Mopar1973Man

-

2001 Ram 2500 KeyFOB

Oh now, I know you'll finish that and get it programmed. I'll have to do the same on my 2006 Dodge...

-

Seat Belt Timing Module

Still better to mod the seat to a later series WITHOUT the seat belt module. Like my truck does NOT have such module and works off of swing weights.

-

My almost new steering gear

I'm in that boat but flipped... Being I'm the Step Dad in this process and trying to help @Jthor with his 7.3L Ford Powerstroke which needed serious TLC. Here soon this will be done. Scary part is I'm getting pretty good with even Ford Powerstroke Diesels now. Scary thought @Mopar1973Manis playing with Ford's now. What will happen next?

-

Truck shakes at 55-65mph, Grinding/vibration when coming to stop as well.

Jack the axle up and then rock the wheel in and out vertically if any movement is felt then the unit bearings should be replaced as a pair. If you feel left to right then its tie rods or drag link.

-

2013 2500

DAP... I'll be getting a set for my 2006 Dodge here very soon. I've done one set for a local gent. Then ive got an old friend that she need a set in her 4th gen Ram.

-

Nv4500 getting harder to get into gear

Oil in the gear box should be fill till spilling out. No lower than about 1/2 below the hole. Typically use my pinky finger bend at the last knuckle and that is my dip stick. Oil in the gear box should be fill till spilling out. No lower than about 1/2 below the hole. Typically use my pinky finger bend at the last knuckle and that is my dip stick.

-

Nv4500 getting harder to get into gear

Something is dragging in the clutch hence why its difficult to shift from a stop. Even like my last failure was similar. The 2nd or Reverse required shifting like 3rd first and then back to 2nd helped. In my case the pilot bearing fell out on to the input shaft. This bit of misalignment would cause the friction disc to drag some. Then after a time the input shaft wore on the main shaft tip from the lack of pilot bearing. Last on it finally took 5th gear with it as it broke the teeth off the smaller gear eating the larger gear. Suggestion replace the hydraulics both master and slave. If no improvement after this, I would pull the transmission and check the clutch assembly as much as no one likes to do it.

-

Nv4500 getting harder to get into gear

Tell tale signs. When you come to a stop and your holding the clutch in and then if after a period of time and the truck starts creeping the hydraulics are bleeding out. I've seen this. Another is if you just press the clutch and difficult to shift the hydraulics could be sucking air in and compressing then the clutch with drag slightly causing a hard shift. Typically in all gears, but not always. Like when my pilot bearing fell out it was hard in all gears till the main shaft was ruined then it took 5th gear with it.

-

Nv4500 getting harder to get into gear

Just do both the master and slave cylinders for the clutch. Still to this day I prefer doing the bleeding myself than buying a pre-bled system that is a 50/50 hit or miss if it will work out of the box. I've seen brand new hydraulics all pre-bled not work at all because air made it back inside the system from the reservoir while shipping and handling of the product. Don't get me wrong the clutch I installed in the 2006 was a pre-bled system from Valair it worked out of the box. The part I hate is getting the pedal throw adjusted right. Where stock systems do not require any adjustment. Be aware adjustable hydraulics is very easy to hyper-extend the throw bearing past the pressure plate. It can do serious damage and you'll be replacing that same clutch over.

-

Seat Belt Timing Module

It should shut down after about a minute or so tops. Like the ECM and PCM typically drop out after about 10 seconds. But there should be no power to that module after a period of time.

-

Coolant leak from back of head

Only used NAPA, Prestone or WalMart Super Tech coolant. NEVER used distilled water in this truck. 431k miles never had one problem coolant changes are typically 75k miles. Last time I pulled the head off and look down in the coolant jacket is was just like I said surface rust of the cast. Freeze plugs look brand new yet. OEM water pump is still going. Never had an overheat condition and never had any issue with freezing. My irrigation water comes from a creek about 1/3 of a mile back and been using this water for flushing the block and refilling with coolant for the entire 18 years of this trucks life. Typically from April on the winter fronts comes off and the truck gets the engine power washed nearly bi weekly.

-

2013 2500

That is a nice looking truck. Just keep in mind to keep up with injector changes between 100k and 150k. Just diagnosed a 2015 Ram with 189k and it call errors for all 6 injectors. I've got a second 3rd gen with wait to start light on for 2 years now his truck won't start because it can't build rail pressure.

-

Seat Belt Timing Module

Most of the salvage yards around me don't even have a diesel truck in them. most are bought before they hit the dirt. $17 for two modules was a damn good deal. The reason to pop it open and look for damage might prevent plugging in the new module to have it burn up in a short time because of a wiring issue, short, or bad solenoid for the lock control. Another option is to find a seat from 2000 to 2002 you should the newer design like I've got then ditch the whole module issue. Might take a bit of work to get seat belt light and stuff right. Like my truck the seat light is directly control by the driver side seat belt latch. That's it.

-

Seat Belt Timing Module

Might open up the old module that is damaged and see if you spot any burnt parts or circuit board it might give clue on how to protect it from failure next time.

-

Coolant leak from back of head

Some needs to keep up on the coolant changes. Freeze plug only go bad if the coolant is change often enough. Once the coolant ages then the soft metals like freeze plug are the first to go. Go job on getting that plug stuff in that hole. But yeah mine gave up on that very corner. Head curl. Sorry on the head gasket. I tend to not think about the freeze plugs being I do keep up on the coolant changes and there is virtually no rust in my system. Just surface rust from being exposed to the air.

-

Steering near impossible when slow or stopped - 2003 2500 5.9L Cummins

The only thing I can think of is the pump is just tired out and possibly pushing debris through the system. I would replace the pump and then blow out all the device backwards. So blowing back through the steering box on the return side to push anything out of the power valve. Then the same with the hydrobooster blow it out on the return side. Hopefully you find the reason for low pressure either a restriction or pump issue. I would change and flush the fluid on that system too. The steering box along could hold up to close to quart. Plus the 3rd gens have that small cooler it holds quite a bit too. I would blow it all out backwards and change the fluid. If you can replace the pump too.

-

Steering near impossible when slow or stopped - 2003 2500 5.9L Cummins

I've gotta ask what size tires? Then do you know if you got a quick ratio box or standard ratio steering box? If your running oversized tire make sure to have only the standard ratio steering box. Quick ratio will have too mush stress and more prone to steering box failures. Quick ratio is not design for larger tires. What color is the ATF in the reservoir? Bright red or darken? Do realize that the steering system is complete designed by Ford. (Truth!) Hence why all truck after 2003 switched out all the Sagnaw steering box, hydrobooster, and power steering fluid to Ford steering boxes, hydroboosters, and ATF for fluid. This way they could hopefully upgrade the steering which, I've not seen anything great on this side either being they fail the same way the Sagnaw boxes did from 2nd gen down. I just got done with a 2005 Dodge with a wiped out steering box and he's running 35 inch tires. Even added a steering box brace for this. Hoping it hold up better. Time will tell... Hence I've got my 2006 in the yard I still got to straighten out the steering in that by ditching the 2 inch leveling kit so the caster returns.

-

2007.5 Dodge 2500 6.7 fog light conversion

I would bypass even the factory lighting being it low quality any ways. Way too much options out in the LED world that product way more light for a fraction of the power required. When you taking the fuses for tail lights and marker light and changing to a 5A instead of 20A fuse. Yup. My PIAA LED driving light only draw barely 1.5A for two 18w LED light that happen to be brighter than my Morimoto HID's which is barely 3A draw. Just compare the factory headlight have a 15A fuse per side, then my old seal beam fog light required a 20A fuse for just two bulbs to be lit. Between LED and HID lighting there is much better options for lighting. The biggest problem is the reflector of the factory light is typically poor pattern anyways. This on reason I switch to HID's because every good clear lens headlights with LED's with a poorly designed reflector the pattern of light still sucks big time. So people try for bright or better lighting on a poor reflector which is where the blinding people start to happen. Even if every thing is legal for street. Like I said the weakest link is the poor grade of reflectors or optics. I will have to give credit to a old member which I think has pass on @flagmanruss he was always after me about this and now I totally understand... You'll never find any quality lighting till your optics are quality. This why I'm a big fan of the Morimoto HID lighting because there is no reflectors and everything is cast out through a lens (H1 Mini or D2S lens). The pattern is perfect and light being cast is smooth and no hotspots. Even the Morimoto LED version was the same thing. Very clean pattern. Back to fog lamps I went with PIAA LED's again design with a very clean pattern and optics are very precise. There is two styles of lights there is the driving lights which is a narrow pattern but long length of cast. Where the fog lamp is very short length and wider pattern. Again I've tried both the driving light cast more light farther down road at highway speed where the fogs didn't quite cut the distance very well.

-

need help deciding on a turbo

How deep are you dipping retard in your timing? Watch the timing value and tell me the lowest you see when you get into the throttle part way. Basically if you retard the timing you are adding more flame front to the turbo. Spools much easier. I'm only +50 behind you with 7 x 0.10 injectors. Turbo isn't as big (60/60/12) vs yours (63/74/12) so you going to need more retarded timing long to get the turbo spooled up. Once spooled to about 5 PSI then you can start flipping back to advanced timing. I would go for 200 HP injector...

-

Dirty turbo vane and what to do about it.

Wow. I better stop power washing my engine, underside and the truck body after 18 years. I've gotten the BHAF wet a few times to. No issues. Not like soaked in water but slash from road ways or indirectly spray while washing the engine down.

-

Seat Belt Timing Module

That would be my call right there asking if Module Master would do it or Auto Computer Specialist out of Florida.

-

Dirty turbo vane and what to do about it.

I might have an old filter hanging around I'll look for it.

-

Daily driver tune for bigger injectors?

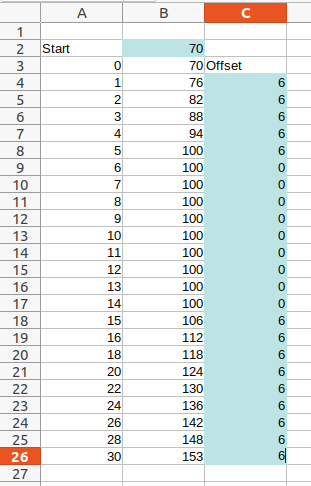

Try this fuel map and see how it performs... This most daily driver style. More stockish on the streets till you lay down and build above 15 PSI then its off to the races. I'm not sure what your normal cruising boost is like. Then Timing wise start at 13° and go up by +5.5°... 13.0°, 18.5°, 24.0° then 29.5° this should work really good for 6 x 0.013 injectors.

-

Moving to almost the great white north.

Good looking truck!

-

Dirty turbo vane and what to do about it.

Not quite. If you cut the filter media out and laid it out flat the BHAF is MUCH larger over the panel filter being each pleat is wider so when flatten out nad measured the BHAF is much bigger than what your numbers are. You can't just measure the outside and do math you need to cut the media out of an old filter and measure the actual media on a flat plane not all folded up in pleats.