Everything posted by Mopar1973Man

-

Drawstraw Users - How low can you go?

(Gotta say thanks for the other info) Basically the fuel get above 150*F creates asphaltenes that make a material that is like a tar sized at about 2 microns. I'm thankful I use quality filter on the AirDog and the stock filter can. I'm double filtering. Then since I don't return and pump out of the sender basket my fuel stay much cooler. Since I kept the stock filter can I still have my WIF light functional, the electric fuel heater is still working, absorbing heat from the manifold, etc. Being my fuel temp hovers with IAT temperature with (+/- 5*F). My filters go upwards of 60,000 miles. Back when the truck was stock everything. I had problems with asphaltenes building in the fuel filter. Now with the AirDog 150 flowe enough to keep the over flow valve open and double filtering my VP44 stays cooler than most and double filter protect the internal parts of the pump from wear. Then if you add 2 cycle oil on top you now just gave the VP44 the best chance of living a super long life.

-

Left turn signal working wipers

Other way is to smack the pin in the Torx screw and break it off with a small hammer and punch. Super easy.

-

Possible Game Changer for lighting our trucks $211

That's one thing Morimoto HID's D2S Lens, does not have is pair of hot spots. The light is evenly cast over a surface. Then it cast farther and higher that most all other solutions. Like @dripley photos the two hotspots won't be there. Now expand the light cast along the edge of the road out another 50 feet out both directions.

-

Battery group size?

I think it's a group 27 IIRC. 31 might just squeeze in but typically the tray is quite big enough. Stock requirements is 750 CCA. Like the Walmart batteries I got are 810 CCA. More than enough to handle subzero starts for 10 plus years.

-

hx35 info

That would not be much of a upgrade looking at the exhaust housing its a 9cm2 or appears to be. A true HX35W would be 54mm in compressor wheel, 60mm on the exhaust turbine, then the housing is 12cm2. My HX35/40 Hybrid is 60mm compressor, then 60mm turbine wheel, then the housing is 12cm2.

-

Battery Temp Sensor question

Yes that is good. I'm set to the same time delay. Quadzilla yes. Cummins ECM No. The ECM software will cancel if you touch the brakes. Usually as the time runs out mine snaps instantly to 1000 to1200 RPM. On cold morning it might hang a bit low hanging at 1000 to 1100 RPM it not set by RPM on the Quadzilla but rough fuel amount. Yeah. That normal as the grid heater fires it drawing roughly 95 Amp and with cold start and batteries needing charged the alternator is most likely maxed out hence why when the grid hit the volt needle falls a bit.

-

Drawstraw Users - How low can you go?

Hence why my filter go 60,000 miles with any issues. I rarely ever see fuel temp even near 140*F. @LorenS thanks for posting that temp so now we know 150*F is the point asphaltene start to create. Again I'm not drawing from the fuel basket but from the tank.

-

Pre lift pump fuel filter question

Yes that is the AirDog water separator and prefilter. It does work pretty good at both typically there is most of the water caught here rarley do I ever see water in my stock filter can. I've used Donaldson, AirDog and Fleetgaurd filter all look to be about the same design.

-

Pre lift pump fuel filter question

Could be as short as 15k miles if your getting farm fuel from tank or if you going to the fuel station maybe 60k miles. All depends on your source of fuel and how clean said fuel is before you pump in your tank. AirDog 150 pre-filter and water separator. Now the filter never really ever fills up or plugs on these. When you change the main filter I will shake this on up a bit and the dump it out. Just screw it back on. I only check for rust damage and keep reusing the pre-filter. Now as for that little in-line filter you have to throw it out after a cycle you can't wash then out very difficult...

-

Red Head Steering Box

I just got my 2005 Dodge Ram customers steering box back on Monday. Now Wednesday I'll go to install this box. I'll try and remember pictures. I've got a Blue Top (Quick Ratio) in my truck and its Tight! Like Race car Tight! I did readjust the sector adjustment of the output shaft to get the last bit a of slack out.

-

hx35 info

Can you post a picture of this turbo so we all can see what your working with and then could you shot a clear picture of any tag or model numbers so we can look pu specs if possible?

-

ECM # 4

It's OK but getting up there. I would suggest doing the W-T ground wire mod. I'm still down around 10mV AC (0.010 ACV). It will help a bunch.

-

Battery Temp Sensor question

No, as long as you buying the stock OEM relay made for the truck. They are design to do this job for years. Personally I fire up and get moving as soon as possible. There is nothing worse that starting a truck leaving to idle at 800 RPM having the grid heater clicking on and off to heat the manifold drawing more power than the alternator can produce at 800 RPM. Like I said I typically unhook the grid heater in April and leave it unhooked till October. All this time the relays can do what they want but no power present. But yes starting and leaving it idle 800 RPMs is the absolutely worst thing you can do to the alternator on a cold start. If you had either my high idle kit or the Quadzilla where you can high idle now at 1,200 RPM now the alternator can handle the loads between being it like being driven 20 to 25 MPH and the alternator can cool the diodes because of extra fan speed in the alternator. Back to the batteries if they are weak every time the grid heaters heat then the load majority on the alternator since weak battery normally won't carry much of any loads. Again now you end up with a hot alternator attempting to burn up the diodes.

-

Battery Temp Sensor question

Comes from the ECM. You see the ground is supplied by the body ground and the ECM controls the +12V to the relays.

-

Battery Temp Sensor question

No. Because I was stuck in Ontario at night without a alternator so I cored it out and had it test it failed completely as for what I have no idea since I wan in Ontario and no time to pull it a part in a parking lot with limited tools and knowing my PCM was fried at that point it was done. Still in all... If you short the green wire to ground you get a runaway alternator that is overcharging. No damage to the PCM will occur. Now short the blue wire to ground and PCM will fry. Heat is a sign of high electrical loads. First place to start. Also sign the batteries and/or cables are not up to the task.Weak batteries or shorted cell battery will still cause the alternator to get hot. Just like my landlord at my second shop he was using his winch for long periods with bad batteries and blew the alternator fuse. Again the alternator is not suppose to hold all the heavy electrical loads, that is the batteries job but if the batteries are not up to the task then its handed off to the alternator and in turn shows up as heat. As the load continues the alternator burns up brushes and/or didoes. So far I've never seen winding burn... Here again that glowing bolt is a sign of poor connection again points back to what I said of poor cabling or connections. You could of seen this using the voltage drop test and would of been high volt number there. I'm sure higher than 0.2 volt drop. Remember this same test can be uses on "ALL WIRING" of any vehicle right down to small engines like motorcycles and all the way to semi-trucks. It can be used on any circuit to measure voltage loss as the circuit is running. Optimally you want ZERO voltage drop. Less is better but in the article it calls 0.2 volt drop a fail for starting cables. Now a example of this in action. I had a 1982 Honda Sabre 750cc V4 motorcycle the cluster was semi-digital. When I was riding at night and using my head light and fog lamp (up graded to 100w) both the cluster would spit out weird things at times. This point out I've overloaded the stock ground with the added wattage of the fog lamp. Come to find out the master ground for that motorcycle was under the fuel tank and was only a 16 gauge wire. Only ONE ground. After measuring I was getting 0.3 volt drop on the ground circuit. I added one extra ground up by the headlight and fog light to aid in this voltage drop afterwards drop 5 to 6 mV DC. As you see... That was a change I made to improve light which came at the cost of overloading the master ground after allowing for a extra ground problem was gone. Now using this information this is why on my truck I went the other direction and REDUCED the electrical loads and now gaining ground and not having the alternator issues like I did. I've double and triple check this on at least THREE different trucks. I know the W-T ground mod does work! As for the parallel ground does not gain anything in the THREE othere truck I've try it on. People tend to forget I'm not just working on my truck and testing but working with many owner and trucks and seeing if there is any change. As for the parallel ground it OPTIONAL in my mind and going to do anything for ground performance. Being all them resulted with and without parallel ground in the 2 to 8mV drop that doesn't change on good master ground cables. I can see it for W-T when hes got linear, ham radio and high current draw with a need for absolutely CLEAN POWER. Any noise is brought back to the radio as frequency noise in the back ground. Hence why he's done noise mods to his AirDog pump to cut out the RF transmission from sparks created at the armature of the pump.

-

Left turn signal working wipers

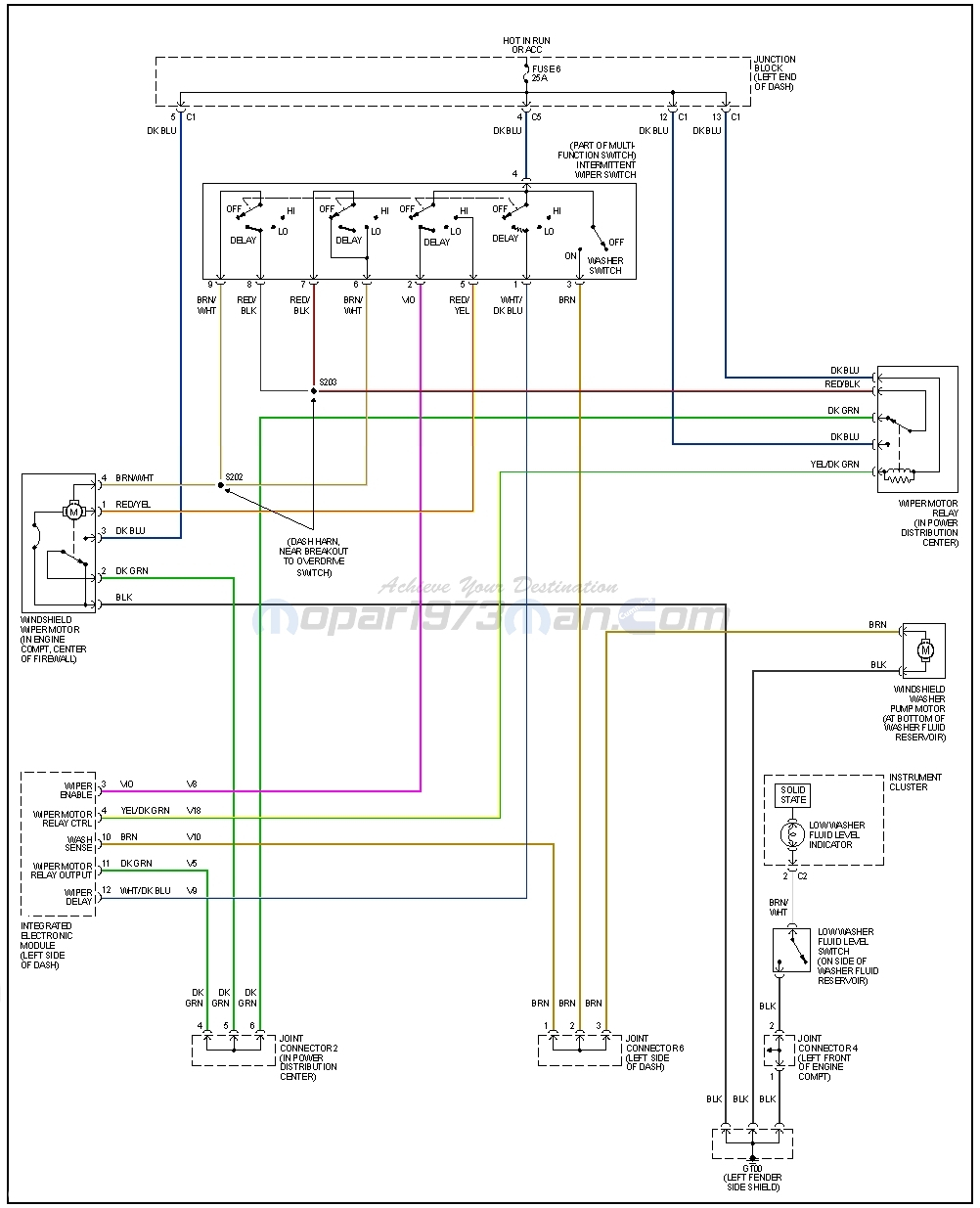

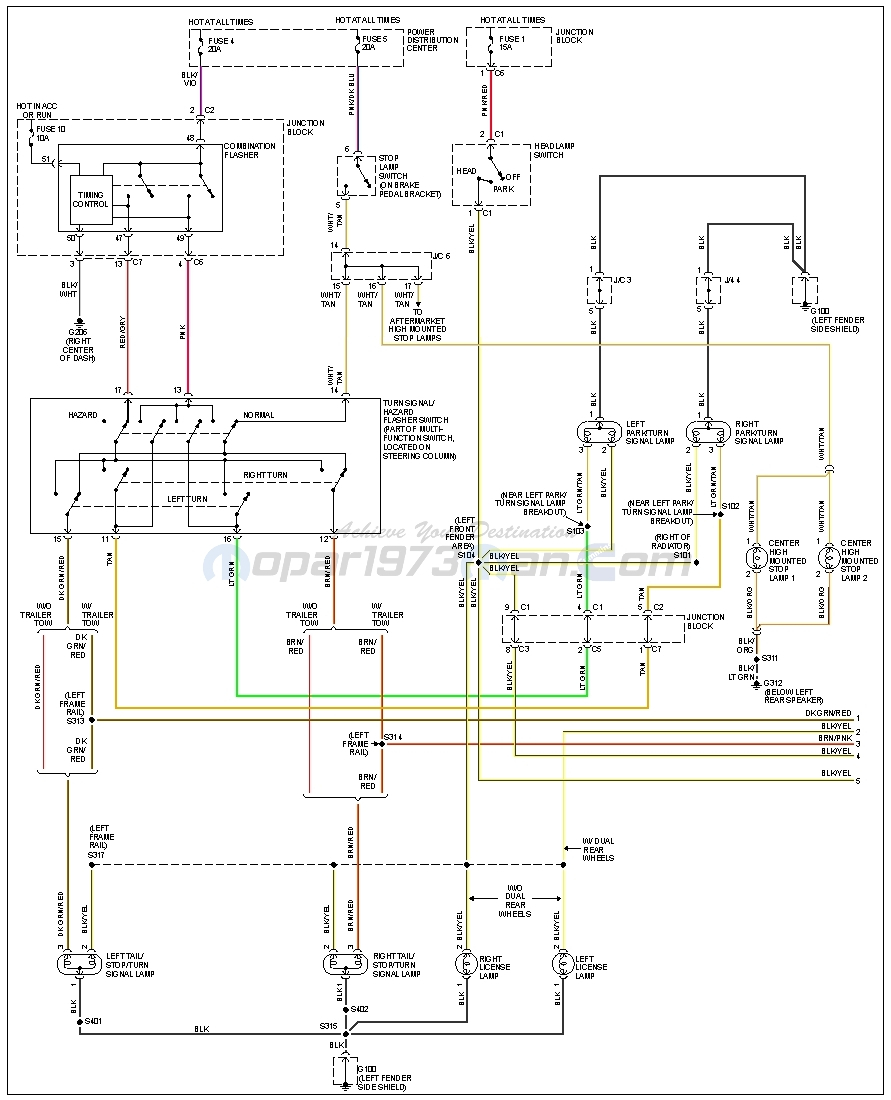

Common though is to replace the multi-function switch first. Being the wipers are typically a different circuit but the contact might of failed and touching off the wipers for the left turn side. Another common issues is usually function quit completely is constant use of the tilt function of the column typically breaks the wires to the multi function switch or the ignition switch. Wipers Turn signals.

-

Pre lift pump fuel filter question

Nice part of the spin on filter you can rinse and reuse several times just check the bottom for rusting issues are you clean it out. Now as for the filter @IBMobile posted does work but like @LorenS mentions there is very little debris holding. No to mention if mounted sideways is will plug up quickly. Where the spin filter typically hang and the debris settles to the bottom when the truck shut down. In all my year with the AirDog now I've never had to replace the water separator till there was signs of rusting started then I would replace it. Ever one that I've cut open had very little debris.

-

VP44 DAP

I notice @IBMobile posted... That right there is actually controlled by the battery temp sensor. As the battery temp rises it can be as low as 13.2V. Then as battery temperature cools then it can be as high as 14.8V. Charging voltage can and will change depending on how long the vehicle is driven and outside temperature as you drive. In all my time driving back and forth to Ontario, OR I can say it can be to that extremes I posted. Hot summer day idling in traffic it can seriously drop close to the 13.2V.

-

ECM # 4

The early ECM's for the 98.5 and 99 was rather weak ECM's and had several issues with the EPROM. I remember a spell where Smarty tuners where causing issues because the Flash EPROM and would only hand like roughly 1,000 re-write cycles and then fail to boot.

-

Drawstraw Users - How low can you go?

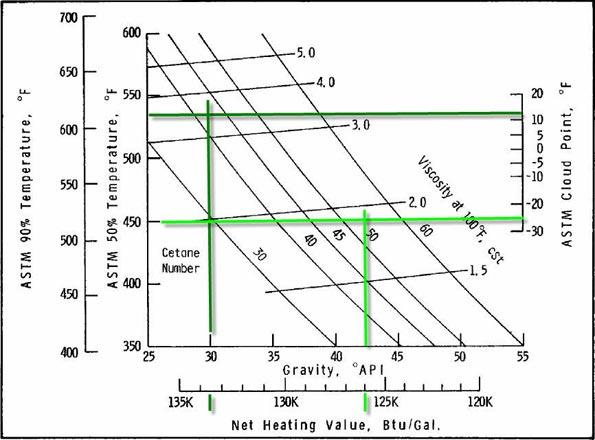

I've got one here but its not cold enough this year for it. I'm not seen any minus numbers and barely any snow at all here. I typically use the 190*F. @pepsi71ocean has been running year round... No issues around New Jersey... The only thing I can say is the thermal efficiency is much better running a 200*F thermostat being most of the expanding heat is converted into work and not absorbed by the cooler coolant jacket. Hence why a lot of gasoline engine started going up in temperature and so did the 6.7L Cummins. Not to mention the 6.7L thermostat does fit our 24V heads. This how you get the 200*F thermostat. I won't suggest this for anyone towing heavy here in the states but up north in Canada and Alaska it would be a good thing. I will say it will keep the cab MUCH MUCH hotter for sure. Fan on lo and temp control way down. Actually my gauge is dead on the money temp wise. As for cetane part of that is refined... ASTM testing scale. You can look up the fuel specification from the manufacture and plug in the values and see what the actual cetane is. This way my local Cennex Fuel station years ago when I did the study. They listed both the summer fuel and winterized fuel as well. Then I found the 55 barrels that they were adding to the fuel when gelling issues where a problem. Light green is winter fuel and dark green is summer fuel.

-

Battery Temp Sensor question

My alternator shorted out on the blue wire side. This was enough circuit to burn a hole through my PCM and never blow the 20 Amp fuse that protects the PCM. All I can say that alternator had a short on the blue wire side. Last alternator I had rebuilt was good but the brushes was fried and had alternator shop replace them for $40 bucks. This last alternator I don't think had any problem but time was short I needed my truck and replace it to find the problem came back and was the PCM protection fuse fell out. So, technically I've not had a alternator failure really since the W-T ground wire mod.

-

Mopar Winter front

All mine are are aluminum sign cut up so they fit inside the grill holes. Bow the metal slighjtly and then only need 1 bolt to hold them in place.

-

Injector questions, which vendors?

Your old than myself... I would of been 8 year old then.

-

Drawstraw Users - How low can you go?

Correct. It basically I get too much tension on the slide rail fork that I manage to slip between the rail. Just gotta be mellow when shifting. I had to fix a 1992 Dodge Getrag 360 for the same this a couple weeks ago. Old Aluminum road sign. The bowed the piece slightly so the bow up in the middle the using a single bolt in each one I can pull the bow down filling the void. Used nyloc nuts.

-

Drawstraw Users - How low can you go?

Not true. When diesel fuel cetane is 45 to 50 cetane it will ignite easy with compression. Now take summer fuel attempt that and you might find a different story. Back when I done my last research of fuel blends they were upping the xylene mixture to increase cetane value. https://en.wikipedia.org/wiki/Xylene Xylene reduces the flash point of the fuel so compression pressure with cold air can still reach ignition point. Hence why most every fuel station up here in the north is all running Winterized #2. More you raise the cetane the lower the BTU's are going to get. Another part why I suggest to never remove the stock filter you gain warm from the manifold for the fuel, then the fuel heater run at any temp below +70*F. Then if you step up to 200*F thermostat you give more warmth (better thermal efficiency) to the cylinder promoting ignition and since the coolant is hotter by 10*F now the manifold will be warmer helping to heat both the fuel and the air. Again way I'm set up my IAT and Fuel Temp are always with +/- 5*F of each other. I use my grill insert to block out the cold wind over the intercooler. Side story I was coming back from Lewiston there was a truck travelling the grade super slow like 45 MPH in a 65MPH waited for my time to pass and when I did I down shifted to 4th too much zeal and would you believe it I stuff the stick in between the shift rails and stuck in 4th gear. So, I ran the tach up to 2,500 RPM holding barely 55 MPH in 4th gear and climb the grade ot the top. By the time I got to the top the coolant was up to 201*F and fan was locking up and I watch both the coolant, IAT and a small fuel temp drop. This example shows that covering the grill allows for unusual issues to be handled. If I was covering the radiator face I would of overheated and been stuck in the middle of the road attempting to repair. Thank Gawd for my set up... I got up top and fix the stick by pulling it up resetting the rails to neutral and drove home.