Everything posted by Mopar1973Man

-

Picking out a new turbo

Like I said final ratio is going to impact the power to the ground. Final ratio between 3.55 to 3.73 really does improve power output. As you seen in the tire adjustment of the Smarty will get you the right odometer reading and show correct speed and miles travelled. Just remember if you return to stock the speed adjust is lost.

-

Tps/intermithttps://mopar1973man.com/topic/17826-tpsintermittent-dead-pedal/tent dead pedal

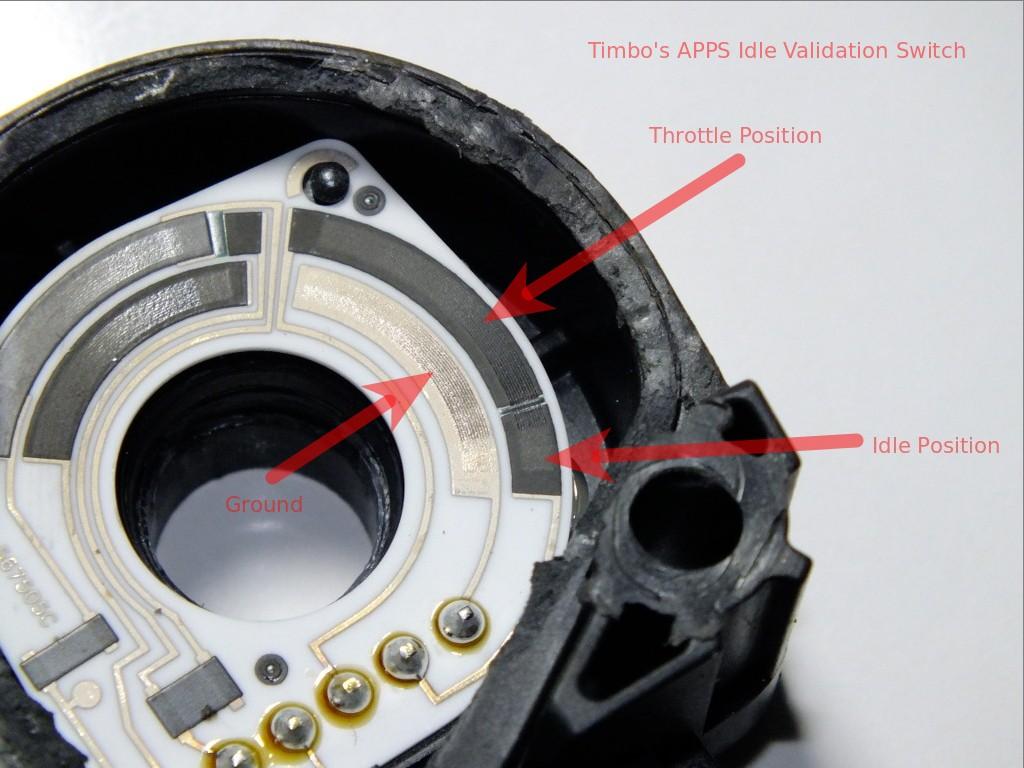

Missing the point of the error its about the IVS switches (Idle Validation Switches). It uses a 5V signal and and toggle the two leads for 5 volt signal. This error is saying that BOTH idle position and throttle position is both LO VOLTS. Timbos APPS exposed there is NO electronics to magic just manual switches. Do the diagnostics on the error code to verify the wiring and then we'll go from there.

-

Normal Load % for Basically Stock Truck?

Are you full 1/2" line between the fuel tank and VP44? I just did a 414 mile trip to Anatone WA to install a injection pump on a Case C580 backhoe. Never got over 120*F fuel temp and even coming home only had about 3/8 of tank of fuel still stayed under 120*F the entire trip. AirDog 150 with 165 Pump. Full 1/2" from tank to VP44 Idle 17 PSI Cruise @ 65 MPH - 16 PSI WOT - 15 PSI. I do need to change my fuel filter getting close to 60k miles on these filters.

-

Bleeding new VP44 and injectors

It will make it tough to start because fuel pressure is too high during cranking you want 7 to 12 PSI during cranking. So this is not a good way of starting up a fresh VP44. You should only open 1,3,4 lines that it. Leave the other closed. Crank it till it nearly starts or starts and close the lines up. Yo should have to open a all the lines. You need some kept closed so the pump can build pressure against something. Once 1,3,4 clear out and pumping then close them and it will start and run on 1,3,4 and now the pump can clear 2,5,6 with pump running. Typically clears fairly easy. I've got one at my house brand new DAP VP44 that failed on first start one of my first ones. Started and ran limited to 1,300 RPM and several error codes. I just got the new pump on Tues day and today got to change it out. Another re-prime and startup. I've gotten to about 1.5 to 2.0 hours to change a VP44 pretty simple.

-

07.5 6.7L Air filter (BHAF)

Still we'll see in time... Gotta wait for him to get here with two batteries and throw out bearing.

-

LED headlight bulb suggestions? The industry has come a long way.

I've got experience and it work great as long as its 3 and 9 position. Good pattern but no where good as a Quality HID (Morimoto D2S). Pattern is hot spotted in the highway has OK shoulder coverage.

-

Sound like a boost leak ?

I've not clean the IAT for over 200k miles. I will never clean it again being it has ZERO impact if its dirt or not. If you monitor IAT temp with the Quadzilla or live data tool you can check ther IAT and Engine Coolant should match at the first start of the day. Then there is nothing wrong and no need for cleaning.

-

Unfair camping

Common by hunters to grab a spot month in advance and leave the RV holding up a spot. Even though there is no vehicle and every left out. USFS fights this every year.

-

NP271 Tcase - Splitting the halves - pointers?

Just make sure you use a soft object to split the case plastic putty knife is good. Small plastic or rubber hammer works good to get it started.

-

Unfair camping

I want to post up this camper that is back at our spot. We came in on Wednesday and found that one camper at our spot. Thursday after work I hitched up and haul in to my spot 7pm. Now the entire 6 days we have been there the neighbor has not be at his camper at all. There is a large 4kw generator sitting there, then his horse shoe pins, chairs out, etc. No one has come or gone in 6 days. I'm going to report this to the local USFS office being its clearly stated you can not drop a RV and hold you spot for later. It clearly state you must occupy the camp site for a max of 18 days. Please don't be like these people and abandon your RV and stuff and think no one is going to steal your stuff or walk away and figure you get to hold that spot for weeks and then show up later. This is no fair or right. UPDATE... I just contacted Payette USFS and they are sending officer out to check it out. Then they suggested that I contact the Adams County Sheriff which I've filed a abandoned RV. I provided them the lat long to both agencies and even offer to go back out if requested to identify the RV. Eileen informed me when she was investigating the RV it had cobwebs on the RV and awing. No foul odors like dead bodies or any sign of foul play. Just like they packed up and left in a hurry. Leaving there massive generator and chairs out. Location - 45.142764 -116.344982 https://goo.gl/maps/mHw73Fbc8ERrM7XK7 RV can be seen here.

-

Brush Creek

Yup. This is why I'm starting this. I'm thinking I want to make a database of all the little spots I know of and if they are free or paid camping. Then list all the resources possible for different spots. This is so others looking now can share into the fun and go to these places. Like I'm back at home now... You can see some of the stuff I packed along for this trip. I've got some firewood from home, my fire pit and grill. My weed wacker to cut back some of the tall grasses and weeds. This keeps snakes and mice away from the area. I was packing my tools for work the last few days and doing work camping more or less getting up early and leaving for work. Even went back and got my 2kw generator so the boys could watch movies at night. Not to mention if you leave and don't have the solar panels out then the batteries don't charge too well.

-

Brush Creek

I push to get the RV tucked into the trees for good shade through the day. Even brought the weed wacker to trim back the tall grass giving a mini front yard by the RV for the grand kids to play. So , @Wet Vette leading the grand kids down into the creek through the Elk Brush. Parker and Kayden. Great shady place for kids to play and the water is shallow so they are not going to drown. @Wet Vette chasing the setting sun with the solar panels. Look back from the road... Out doing a bit of hiking with everyone... The grand kids got a bit tender footed out in the sticks I told them I would fireman carry them through the needles.

-

07.5 6.7L Air filter (BHAF)

Like I said we'll see. Not everyone's truck run exactly like your truck. Just saying...

-

07.5 6.7L Air filter (BHAF)

Next weekend he'll have new batteries so we can get it running soon. Still in all not as bad as most think. He's ran it for 2 years.

-

07.5 6.7L Air filter (BHAF)

When @Taz gets up here I'll verify his truck he's also got a BHAF but I don't think the temps are as high as you think. I can jack into a the OBDII and check the live data.

-

2-stroke oil on sale!

Payette, Idaho the last time I got fuel down there is about 2.179 a gallon and unleaded was another 20 to 30 cents higher. Now up in New Meadows, ID its 2,799 for both diesel and gasoline. New Meadows thinks its part of McCall Idaho and charges this extreme high price. Most likely the highest price in the state. Well go to some of the back country areas and it can be closer to $4.00 a gallon for either.

-

Brush Creek

I'm doing a twist on this camping trip and doing work camping. So I got up this morning at the RV at 7:30am and hauled for the house got a shower and coffee. Waiting on a few phone calls for A/C service up here. Got about a 1/2 day of work then I'll return to the RV for the afternoon. I for got my camera again. Dang it! It's been a wonderful time with the grandkids. Got a couple of cheap dollar store glow stick rockets. We were shooting these thing out in the parking area of the campground till nearly 10pm. Had wonderful Mexican food cooked out side and fire even in the fire pit. We've been there now 5 days and still going with the water on board. Like I said we cheated a bit and had showers back home. Only a quick 10 miles back to the house. Only photo I've got on my cellphone with me... I'll remember to bring home my big camera yet.

-

Looking for some wisdom on longevity of the 5.9 L

I passed up a 2001 Dodge for $4,000 just needed a heater core and the cruise control fixed. Cummins , 4WD, 3.55 gears, 2 inch leveling kit, etc. Black truck, quad cab, lifted up on 35 inch tires. I could of fixed the few problems and flipped the truck for nearly double. The paint and body were in good to excellent shape from the photos I looked at.

-

LED headlight bulb suggestions? The industry has come a long way.

Still plenty bright. Way brighter than halogen.

-

2-stroke oil on sale!

That is the sick thing... Ethanol is cheaper than straight gas. Just like Regular petroleum diesel is more than bio blend. Stupid...

-

What happened to our political parties?

Yeah if we are late on our debts the banks take you home, possibly your car. If the Gov't is late no problem just add it to the national debt. That is the part that pisses me off I work hard for the money I do earn I just get sick and tired of the Democrats wanting to give it away to illegal aliens in the form of free health care, free housing assistance etc. Like myself since I own land I do not qualify for any assistance I have to sell my home first. Just like I found out for my cancer treatment. 74,000 dollars and there is no assistance program for me because of the fact I own a house. I manged to bargain with the hospital to knock it down to 19,xxx roughly but must pay it off in 2 years. If not I might lose my home over it. Now the gov't is will to give away homes to illegal's and pay there bill (water, power ,etc.) Why isn't the gov't helping to take care of the citizens? Why is the Democrats screwing with the stimulus checks and holding them up? I'm going to do a full series of camping spots in Idaho that are free. I'm going to show off out to do camping for cheap or free. USFS that ask for fees are getting too much. It's not like your going to get full hook up or trash services. You get a little slice of ground and close neighbor. No water, no sewer, no power,etc. for as high as $50 bucks in some place in Idaho. For that much you can rent a flea bag hotel. Again why do we have to be taxes again for sleeping in a pad of dirt, no services? Not to mention any campground with a gate right now is closed up and locked. COVID-19 you can't camp close together.

-

What happened to our political parties?

30 years of work and effort. I'vew only got 400w of solar on the house which I want to upgrade. Then I've got a small 200w hydro generator. I've only got a 4,000 watt inverter (120 VAC). I added a step up transformer to give 220V power for the well pump. The water heater is converter to 110VAC and 1,100 watt elements. I even have a mini setup in the RV with 1,200 watt inverter, 35w solar panels. We have stay out for 3 night already and been charging the batteries with just solar. Yes sir. I know a few cheats to making that permit give me more too. Not legal methods but I know how to get more bang for my buck. Yes our trees must be dead to harvest for firewood. Now if it a storm fallen tree where the root wad is attached then you can harvest green trees but that sucks because it much heavier wet and green. Personally American Citizen should be permitted by right to harvest any dead and downed tree for heating and cooking purpose without a permit. We have already paid taxes for the USFS and gov't agencies. Why do I need ot pay more fees for something I've already been taxed for? I should not have to pay fees to enter state parks as a US citizen. Kind of why I'll be posting up all my hidden hide-a-ways where I go camping without fees or permits. Just started my post on Brush Creek.

-

Brush Creek

Ok now that I'm home for a small bit to grab supplies. Brush creek is only like 6 or 7 miles in off the US95. You turn off at Smokey Boulder Road and speed limit is 25 MPH. The road is gravel for the first part. When you get to the fork just hang to the right. Continue about 2 more miles. Brush creek campground is without any services. No water or power. Pack in and pack out. I forgot my camera at the RV. We came out to grab some food we left at the house and grab showers. I've got Eileen two grand sons here too (Parker and Kayden) they are having a blast playing in the creek. We are kind of cheating coming home to shower to help in extending the water at the RV. But easier to do that that break up camp and hitch up to back haul to fill the RV with water. Again sorry for forgetting my camera I'll post it when I come back again.

-

Looking for some wisdom on longevity of the 5.9 L

Like myself I'm in it for a balance of both power and longevity. 7 x 0.010 injectors (150 HP) Holset HX35/40 Hybrid (60/60/12) Quadzilla Adrenaline Biggest thing is not do any lift or leveling kits. No over sized tires stay with stock 265's or 245's. I find the 245's are super great for towing trailers putting the truck in the power band for towing. I average about 20-21 MPG for highway running typically. Longevity wise I highly suggest exhaust brake. Brake pads will last well over 200k miles. Without any lifts or leveling kits I'm getting 200k plus miles from ball joints, tie rod ends, and other suspension parts. Even my last set of Hankook 245/75 R16 tires I got 70k miles from them and two winters. I've got enough power to tow my RV at 65 MPH up most grades without any temp problems. I just done a trip to Mohave Valley AZ and the only thing that got a bit hot was my transmission temp at 190°F to 200°F. Engine coolant stayed at 197°F and EGT's 1,000 to 1,100°F. Maxed out at 14.7 MPG averaged 12.6 MPG with 17,300 pounds gross combined weight. Follow me you will not go wrong... 418k miles on the clock. Give perspective to that amount of miles. It 238,000 miles to the moon, then its 476k miles to the moon and back home again. I'm almost home from the moon! Hidden in the woods for this weekend...

-

Brush Creek

We are out at brush creek up Smokey Boilder Rd. Ill post more about this site when I get home. Lots of photos to come.