Everything posted by Mopar1973Man

-

Mechanical lift pump

Strange that FASS and AirDog both put pre-filters on and causes no strain on the pump. Is the might mechanical pump that weak because it nearly double the distance from the fuel tank now at the very front bumper? Hmmm... Pumps are not design to suck or pull fuel long distance they are designed to PUSH fuel. This is where the weakness is being the pump must be located at the crank and adding huge distance from the fuel tank and forcing the pump to pull fuel longer distances and add a prefilter would impact the pump performance. Yeah this is basic pumps 101. The suction side of the pump should be as short as possible.

-

Uneducated second gen owner in need of help

2.5 hours or 125 miles to get to Walmart. https://mopar1973man.com/contact/ My place is on the right. Huge maple tree in the back yard and the two houses make a L shape.

-

Uneducated second gen owner in need of help

I've got to travel 2.5 hours to reach a interstate and to be able to travel 70 and 80 MPH. The rest of the highways I travel are 45, 55 and 65 MPH typically.

-

Uneducated second gen owner in need of help

Yeah I ran about the same coming home. I was hot footing it. Cruise set for 67 to 68 MPH. If someone slowed down I would stomp the loud pedal and go on around. On my way down I was set at 65 MPH and more conservative and not passing as much.

-

P1688 no CEL

This should help out. I've got it down to a science I can typically change them out now in about 1.5 hours. Even though the labor book calls for 4 hours.

-

Uneducated second gen owner in need of help

NV4500 5 speed. That was rebuilt 4 years ago. I've already 120k miles on that transmission already. Running 50 SAE Transmission fluid GL-4 Synthetic. Reason why it was rebuilt was I broke the main shaft in half. What I'm watching is temperatures in all places on the truck and rise in temperature means something is no longer running efficiently. If I drive too aggressive transmission temperature will rise. Very soon I'll have temp sensor in the rear diff cover. Then have a switch on the transmission temp gauge and be able to check the transmission and the rear diff temperature. Also as you make modification and if the mod now make the temperature rise you know your losing energy to heat now. If the modification reduces temperatures on the transmission and driveline then you going in the right direction making it more efficient.

-

Uneducated second gen owner in need of help

After 125 miles from New Meadows, ID to Ontario, OR. Here is my trans temp. Yeah it does help to make it run cooler. Last stretch before entering city limits.

-

Uneducated second gen owner in need of help

Just for info value. Just drove 100 miles and transmission temp floated 130F the whole way. EGTs floating 500 to 550F on the flats. Just had a phone call last night where a guy changed out 37 inch tires and lost control of the EGTs over 1100F for most highway travel. Just met another gent that is fighting get more from his Quadzilla but running 25 inch tires and has to down shift quite a bit to control EGTs. Tires do make big impact. Just my own switching from 31 inch to 30 inch reduced EGTs and transmission temperature.

-

Brakes, power steering

More power steering fluid. Flush till the return hose runs clear and clean.

-

Smarty s03 today :)

Smarty just isn't a very controllable tuner. It got its short comings. Fuelling map or the timing map doesn't fit every single circumstance. No matter how much you play with it you never get what you looking for with knowing what the timing map and fuel map look like.

-

Brakes, power steering

Should consider yearly being brake fluid is hydroscopic.

-

Uneducated second gen owner in need of help

Be careful. You might possibly alter the final gear and create issues. Very common problem people want the truck to look cool. Put bigger wheels and tires on foul the final ratio up and end up with high EGT's, lower MPG's, and front axle issues. I just got off the phone with another gent just put 37 inch tires on and complaining off super high EGT's and extremely low MPG's and asking how to fix it. I hate to say it but change the gearing in the axle to 4.10 before changing to larger tires! Optimal final ratio should be 3.55 to 3.73 to the ground. Do the transmission BEFORE the tires. You end up killing the transmission with the tires (if oversized). Bigger tires typically trap torque in the transmission creating more heat and failures.

-

NEW FASS Signature Series Diesel Fuel System "What are the Big Differences"

The only time my AirDog got loud is when the motor bearing gave up. Now running 4G AirDog pump and motor so far so good!

-

Uneducated second gen owner in need of help

Ive seen too many people try to build the dream truck in one pass. Go out and by 200 HP injectors, twin turbos, 5 inch exhaust, Quadzilla or p-pump. Then wonder why the truck sucks, too smoky, always broke down. Like myself I've slowly learned what is required for each step as time passed from 2002 on. Back in the day a good day driver was RV275 injectors and a tuner. Now you can actually start out at +75 HP injectors and Quadzilla. Too many make the lofty goals of 500 HP and up and have no idea what they are getting into. I say build slow and in stags and learn about the truck and what you need before jumping too far and over doing.

-

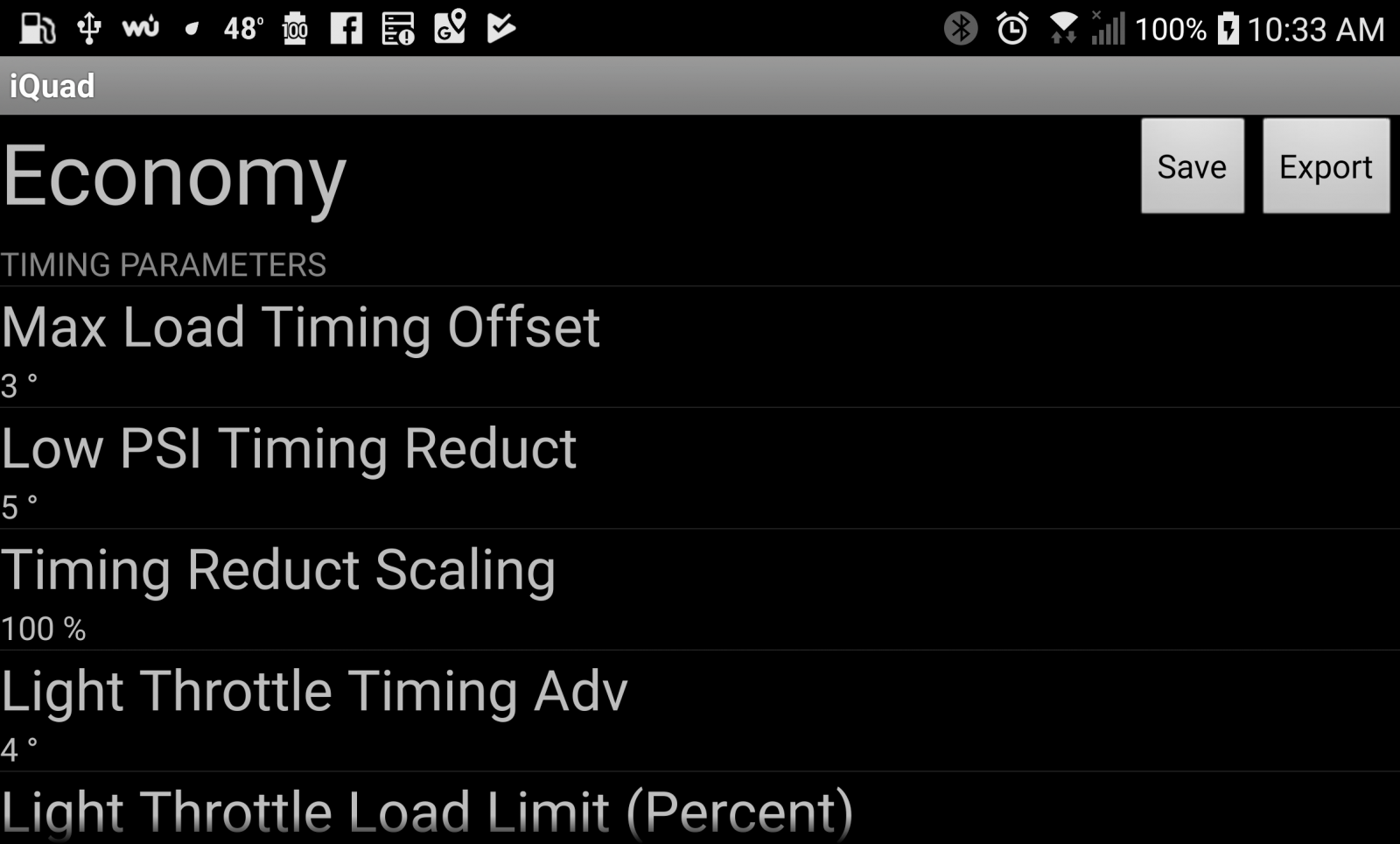

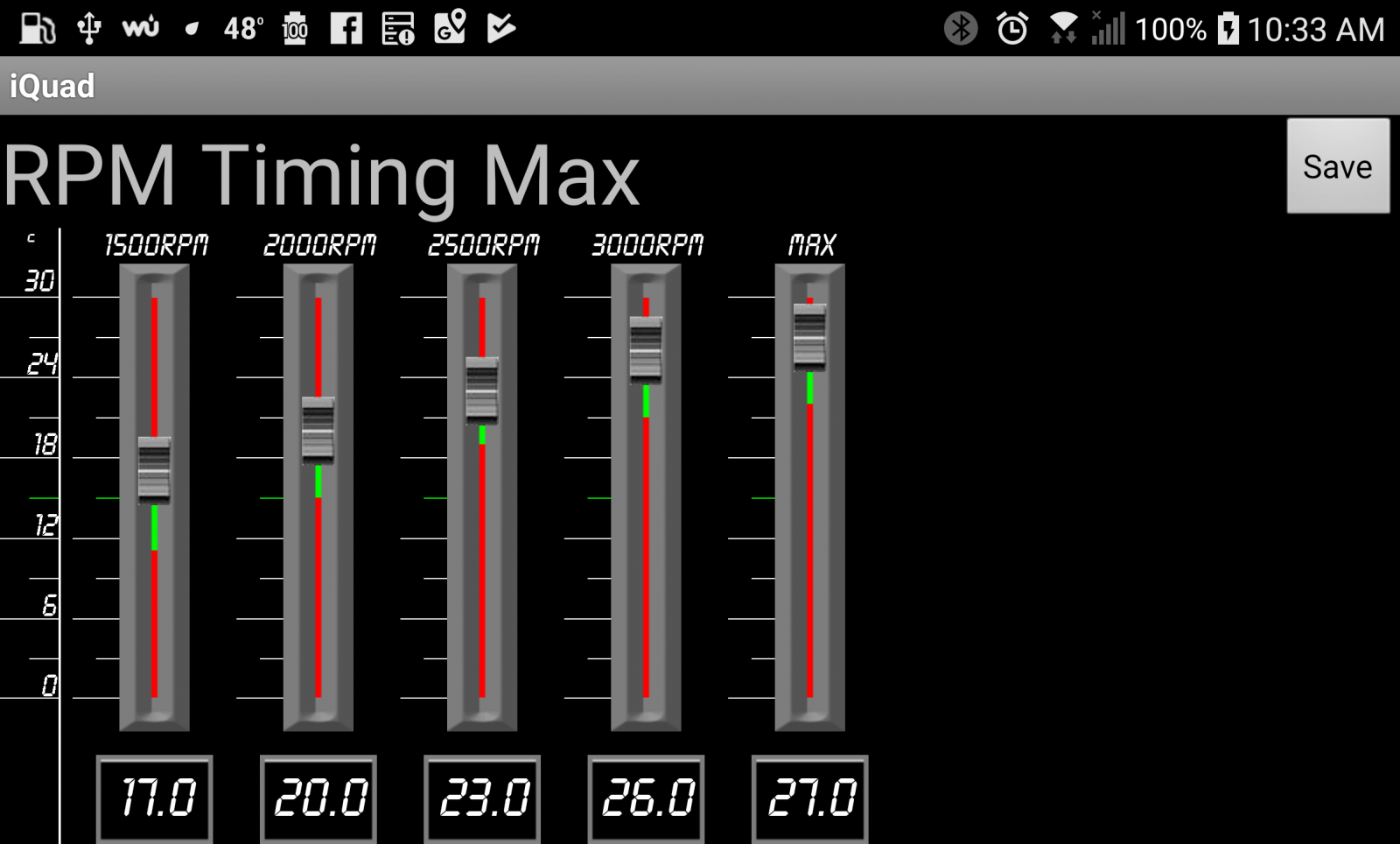

2000 3500 no power,sucks fuel like it's free

Smarty S-03 is very limited tuner. No adjustable timing or fuel maps for larger injectors. It was design around a stock injectors. Quadzilla has full fuel table control and timing control to fit your fuel system. Like Smarty S-03 limits to 19° BTDC for timings for most settings. Like Quadzilla and 7 x 0.010 @ 320 Bar injectors I run 24° BTDC timing which cannot be done on Smarty S-03.

-

Brakes, power steering

30k for power steering fluid, and brake fluid. Manual transmission is considered life long fluid. I was changing every 100k miles now with 50 SAE changing at 50k miles.

-

2000 3500 no power,sucks fuel like it's free

Yes it all goes to the site. I only get a cut of what left over after bills are paid. If the income is low I lose a paycheck or its really skinny like April of $20 for the month. Check cost me a 250 mile round trip to the bank to process. No longer have a local bank. Then I need to transfer the funds from my personal account to M73M Paypal account. When you use the debit card. I don't have to drive 250 miles to a bank and back and then I don't have to transfer funds. Its directly deposited in the Paypal account. Much easy for the bookkeeper to keep up with.

-

Uneducated second gen owner in need of help

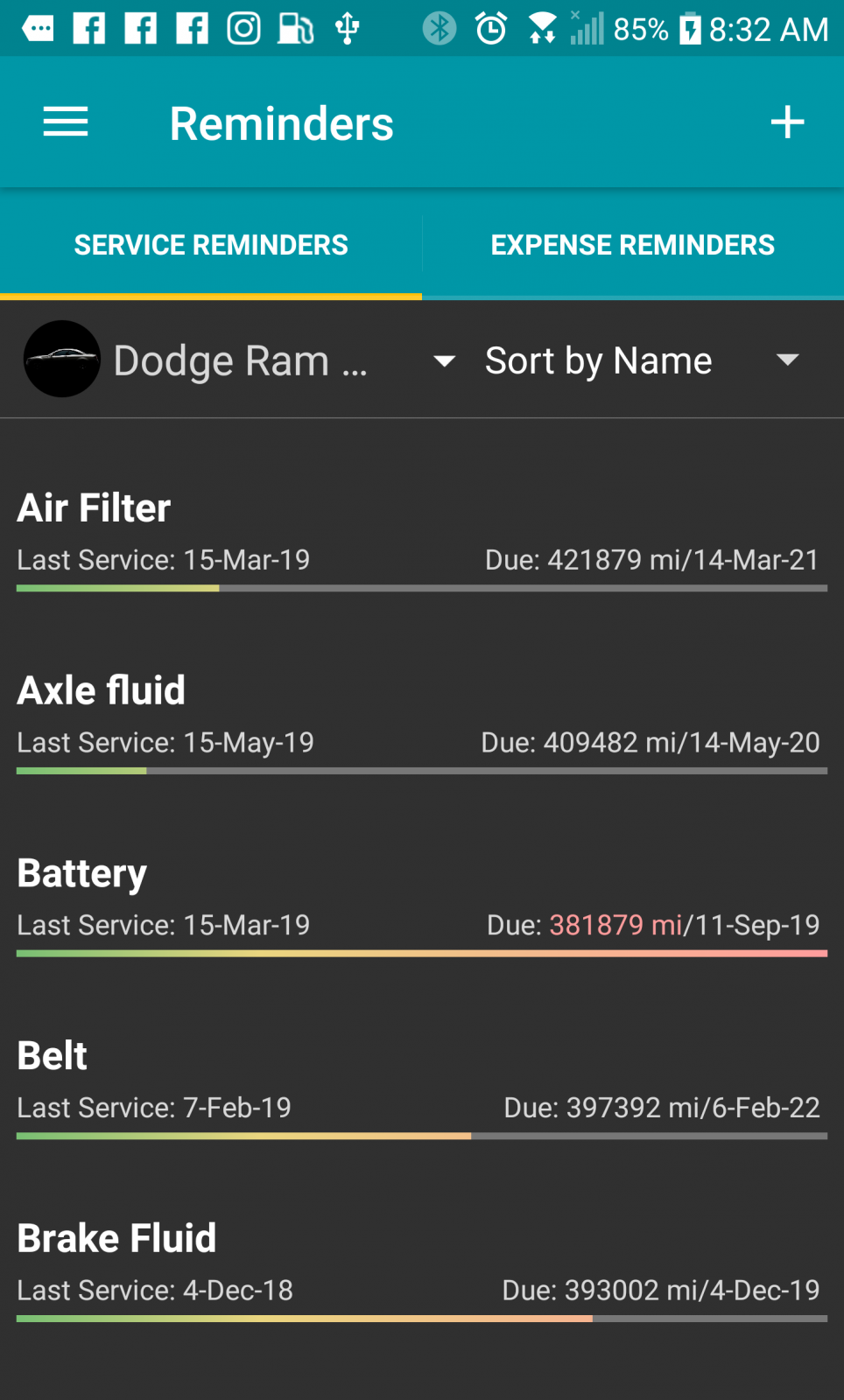

My suggestion... For those with a bad case of CRS (Can't Remember S___) Download this app for your phone. https://www.simplyauto.app/ Now track all your fuel and maintenance on your vehicle. Even warns of when thing need to be taken care of. About 3 years of logs...

-

Uneducated second gen owner in need of help

Yup. That is very true. Best to build in stages. Like other have suggested take care of the repairs first. Then do your upgrades. Best to build slow and in stages.

-

Uneducated second gen owner in need of help

I'd gladly do that task. Just did that exact thing for a gent down in Parma, ID. Meet him for the first time and looked over his truck and gave him a task list to look into. Then next we'll start talking labor and what jobs I'll do.

-

Heater core

I've been using that for a long time. What have you been drinking? Better start sharing...

-

Heater core

Hmmm....

-

Uneducated second gen owner in need of help

When some one calls that is the total height of the tire. 3 numbers are... mm measure across the tread, then the next number is percentage of the tread face in the side wall height, then third number is the wheel size in inch. Like I run 245/75 R16 tires. 245mm (9.64567 inches) across the tread. Then 75% of 245mm is 183.75mm (7.23425197 inches tall), and 16 inch rim. https://tiresize.com/calculator/

-

2000 3500 no power,sucks fuel like it's free

The problem is I'm the only website left not owned by a corporate. I'm privately owned and have no umbrella when a big company could infuse money in. Everything else out there like CF is owned by AutoGuide.com, DieselBombers is owned by Internet Brands, etc. I'm just a single guy trying to hold my own life on a wire with cancer (finally clear), then taking care of Mom with Dialysis. The last few pay checks are well in the cents per hour. (April paycheck was $20 for the month) We've been leaning on only 2% of the membership pool to keeping the bills paid and and possibly make a bit of profit myself. Advertising is very random some months are good other are barely going to pay the bills. This was the only way to make it fair small amount from everyone. Site bills have always been paid but my own bills I've had to struggle working other jobs just to keep my own head above water. I refuse to sell the site to corporate owner. If I close it down, the information will be gone for ever period. Still the same method. Just spreading small amount by all. https://mopar1973man.com/subscriptions/

-

Brakes, power steering

I've been doing the fluid flush without the engine going. You need to pull the steering box return not the hydro-booster. Now cap the pump off so it holds fluid. With the axle jacked up slightly now just unlock the steering wheel (engine OFF). Now go lock to lock slowly and the steering box will pull fluid all the way through the system. I typically flush a quart through the system. It hold slightly over a quart dry.