Everything posted by Mopar1973Man

-

PLEASE HELP NO GAUGES NO BUS

ECM internal error. Most likely going to require sending the ECM for repair.

-

Firewall insulation ripped.

It's been so long ago I forgot what it was.

-

Parking brake adjustment

Yes got an article for it.

-

Trickle charger with quadzilla tuner

Awesome idea for people that randomly drive their trucks.

-

Firewall insulation ripped.

Just plastic snap fasteners.

-

Trickle charger with quadzilla tuner

No issues here 2 / 6 Amp charger never bothered the Quadzilla.

-

Firewall insulation ripped.

That matting does nothing for sound. It does make great mouse bedding all over your engine. Then if you have an oil leak it soaks up oil and the sags down on the engine. It is great for dumping tons of dust and dirt in your valve train when you are doing valve lash or injectors. On both trucks, the hood mat came out and the firewall mat came out. No loss...

-

Fuel Pump Wiring Diagram 2001 Cummins

No fuse or relay in the stock ECM fuel pump control. The FASS should have its own fuse and relay setup.

-

Lets see what guns you "don't own" :shifty:

Thief - This is a hold-up. Trreed - Let me go back to my truck and unlock my gun so I can shoot you. Thief - "BANG" Trreed - .... A locked up weapon is worthless. A weapon left behind in your vehicle is worthless. A weapon locked up in a gun safe is worthless. Average 911 response time here in my area is better than 1 hour. You better be able to hold your own for at least 1 hour.

-

Morning Pic For Today...........Post A Pic around your place.....

Worked out...

-

Need to ground my tool box.

Well errr OK. I thought that's what the 3rd round pin for was grounding. If the cord inside is the green wire is attached to the toolbox metal then just plugging in the plug should ground the box. Having GFI plug in the shop just makes it even better.

-

a soggy PNW hello

@Brent B3HH I think you get the drift I've got a bunch of nuts all over the place. You right near JAG1 there in Beavercreek. @JAG1 Not yet we are still in thawing phase up here. Might be a long while for any forest camping. @IBMobile Pink Floyd I never would have figured...

-

Lets see what guns you "don't own" :shifty:

Kind of doesn't work too good when it's in a box with the trigger locked. Works much better on your hip ready to go loaded. Like mine is loaded and worn nearly daily. Never leave home without it. Firestar 9mm Made in Spain...

-

New Toy

The first problem I see... Windows... Yuk!

-

Qaudzilla woes

I just had some wonky limits set that when the wiretap hit it would bang the rear axle, then suck you into the seat. Once I played a bit and got the limits set about right then the wiretap mellowed out a bit more.

-

PLEASE HELP NO GAUGES NO BUS

Ummm... Those are cluster codes. Another issue to itself. I need you to plug in an OBDII code reader and then report back the error codes. Don't bother with the key trick it's not reliable.

-

Fuel Pump Wiring Diagram 2001 Cummins

The P1694 is a communication error with the ECM which is not responding. I also agree you need to ditch those pumps and get to a full FASS or AirDog fuel system. Anything that uses the stock lines will never keep up with volume while under load. Fuel pressure needs to stay between 14 to 20 PSI.

-

Help offered request

Around here I'm sorry to say it rather tough for work too. I'll keep my ear open for any leads though.

-

Firewall insulation ripped.

No longer in my truck removed all that junk.

-

Getting ready to tow

Exhaust brake is a good suggestion. Drill and slotted are prone to cracking and warping easy. I just made a post about my brake inspection 190k on my pads still over 50% life. Maybe 300k ill change them. Still got my OEM rotors. Now climbing watch the Pyro it passes 1,100F downshift and kick the RPMs back to 2,000 and hold. I do 750 to 1,000 miles a week!

-

DYI- what do you do yourself vs have done?

Nope... You'll need an Android because the Quadzilla runs on a Smart phone or tablet. Time to upgrade?

-

DYI- what do you do yourself vs have done?

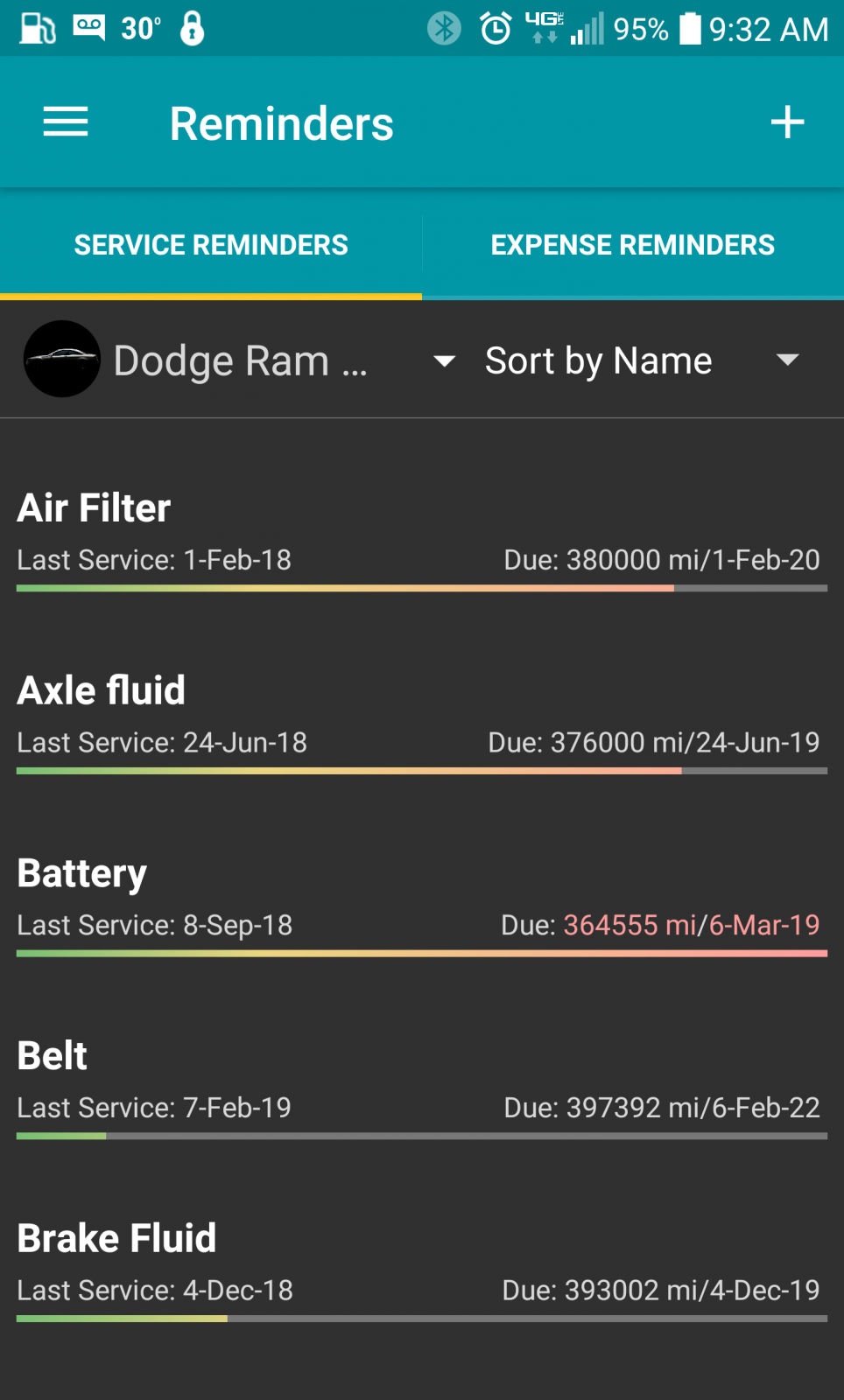

I use an app called Simply Auto. It tracks All my fuel and maintenance. As for mods... I would do it all over again. Most of them I've done the study work before actually doing any mods. I'm not racing type but long haul. Different design.

-

a soggy PNW hello

I'll have to personal whip some tail for that... West side get together... Hmmm... Depends on the location.

-

2002 24valve Complete dead pedal

Looks like its time for a Timbo's APPS.

-

PLEASE HELP NO GAUGES NO BUS

Error codes? There is something going on with the PCM. The PCM is the master computer which starts the CCD Network without it the cluster will throw a No Bus message and then the gauges don't work. Possible P1698?