Mopar1973Man

Owner

-

Joined

-

Last visited

-

Currently

Viewing Topic: Beast - 500k miles - Projects

Everything posted by Mopar1973Man

-

Transmission dip stick question

Must be only a 47RE issue. My 46RE in my 1996 Dodge 1500 doesn't have this issue. I'm pretty sure there is a vent hole in the dipstick tube somewhere near the top.

-

Vp44

T-bred... I would have documented all serial numbers and made photos of your pump just in case they claim it void warranty because of bad fuel. I'm not sure who supplies there pumps. Sad to say I've seen quite a few voided warranties with T-bred.

-

Good buy or no?

One of my few hand me down tools given to me from a member. Here is like Harbor Freight... https://www.harborfreight.com/radiator-pressure-tester-kit-63862.html Here is Home Depot. https://www.homedepot.com/p/Steel-Core-Radiator-Pressure-Tester-Kit-16-Piece-39411/303479578

-

Change to Limited Slip

Being I travel 65,000 miles per year in all weather conditions from rain to snow. I've found more wide tire and lifted trucks losing traction and slowing way down (25 to 35 MPH) where I leave my cruise set and keep rolling right on around them. Like last winter I was able to travel 55 MPH on packed snow and rarely had to use 4WD. Even in downpour rain the only thing that slows me down is loss of vision because of the windshield being bombed by too much rain or snow. Surprising what just a mere inch of rubber change can do for stability or power.

-

ATF Oil Change. Service Manual Capacity Incorrect?

I know a true empty 46RE (just rebuilt) will hold around 11 quarts.

-

Rpm jump

Typically if there is any AC noise it will do weird stuff about 80% of the time its alternator related. The other 20% could be bad crank/cam sensor. Wiring issues. Bad grounds. Possibly cluster error.

-

Loud Circulation Fan for A/C

Idaho roads. Rancher doing his typical work with cows. Feeding hay, herding them, etc. There is a cheat. Not a perfect solution but it will work for about 80% clean up. Pull the blower and the resistor out. Lay a tarp on the passenger side footwell. Using a garden hose and spray nozzle you can rinse out the evaporator in bursts to hopefully not flood out the HVAC case and run it on the driver side. This should wash out all the packed dirt, grass, leaves, etc. Just make sure to check your A/C drain after this wash. This typically can improve airflow and reduce noise too. I've done this on 2nd Gen Dodge's, 3rd Gen Dodge's and even one Chevy truck. Worked good...

-

Change to Limited Slip

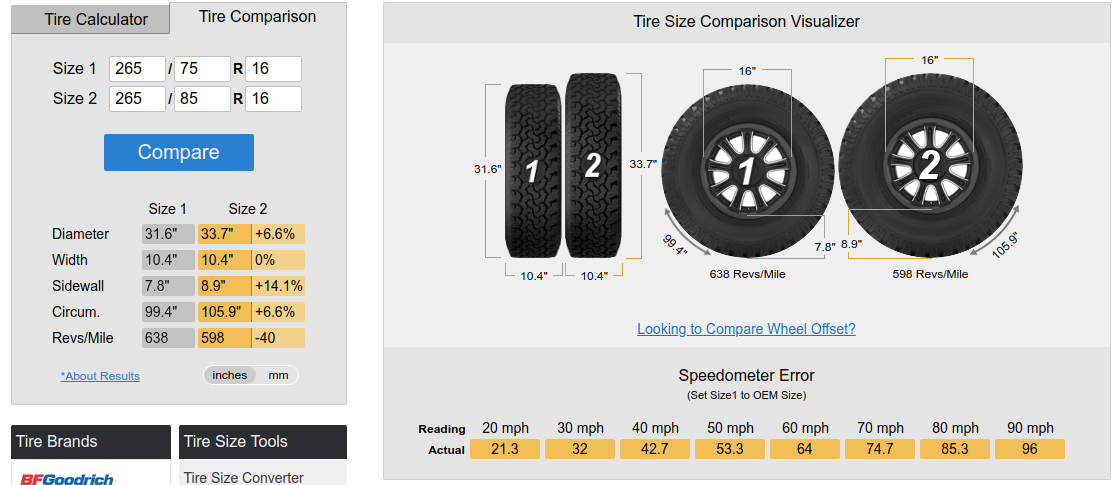

No. Front axle is always an "open differential". Only the rear is optional of "open differential" or "limited slip". As for pulling power, it done on both wheels on that axle but when a tire loses traction it will continue to spin. Where a limited slip uses a clutch pack to lock the axle solid and give traction to the other tire possibly. It doesn't mean it can but that is the concept. In 4WD my truck pulls straight on all four tires. But since I use smaller / narrow tires my traction is better so the whole slip part is rare for me hence why "open differential" still works just fine. Now for guys with wide tires or duals now this is a whole another story where traction is lost easily and "limited slip" would be a good band-aid for this case. Guys will duals you basically taking 2,860 pounds dividing by 2 giving 1,430 pounds per dual set. Now since the contact patch is much wider and spread of weight of larger amount of cubic inches traction is lost really easy. No clutches... Limited slip Dana 80... As you can see the clutches. Towing and daily driving optimal you want 3.55 to 3.73 final gear ratio to the ground. So like in my case with the factory tire size is 265/ 75 R16 with 3.55 axle gears now change up to 245/75 R16 (the other factory tire size) now my final gear ratio to the ground is 3.69:1 which is darn close to 3.73 ratio. This puts me at a perfect 2,000 RPM's at 66 MPH in 5th gear on NV4500 transmission. At 85 MPH your twisting nearly a perfect 2,400 RPM's.

-

Quad cab rear window detached at hinge

Can you shot a photo of the original joint and the glue used possibly?

-

HELP... 24 Valve rough idle when hot

Might get it to the stag of missing then test again. I'm wondering if a diode is failing when it's getting hot and creating the issue? Keep an eye on it and see what happens. As for something that might just buy time for that current alternator in the W-T ground wire mod. As you'll see the ECM, VP44 and other sensors have the alternator noise running past the master ground for everything. Black/Tan is the master ground from the passenger battery and the solid black is the alternator charge lead.

-

Loud Circulation Fan for A/C

-

Change to Limited Slip

- HELP... 24 Valve rough idle when hot

Ok so the injectors are covered. That leads me back to be sure the power and sensors are not getting AC noise.- HELP... 24 Valve rough idle when hot

Ok. Did you tighten the injectors in the right order? Crossover tube seat it lightly. Torque the Injector hold down caps to 89inch/pounds. The finalize the crossover tubes.- Loud Circulation Fan for A/C

Blower noise could be debris in the blower cage.- HELP... 24 Valve rough idle when hot

Test your alternator for excessive AC noise. Miss at hot idle is typically a sign of worn out injectors and the pop pressure is really low and the injectors are getting pissy.- ATF Oil Change. Service Manual Capacity Incorrect?

That looks stock for sure. Steel pan. The extra deep typically are aluminum and nearly twice as deep.- Rpm jump

Being AC noise will foul anything with a hall effect sensor like crank sensor or axle speed sensor I typically want to be sure the alternator isn't the cause first.- ATF Oil Change. Service Manual Capacity Incorrect?

I guess it's off. I just want to be sure you not judging against someones oversized pan. Lot of people add a deep trans pan to the truck. So it rather rare to find them still will a stock pan.- Change to Limited Slip

No. Makes the truck hydroplane more. The only time wide tire is a good idea is offroad in mud. Now a wide tire will float on top of the mud spreading the axle weight across your "wide snowshoes" and allowing you to travel without sinking. The rest of the time narrow tire provide better traction than wide tire because even in a panic stop a wide tire will break free and skid sooner because again your weight is spread out over more cubic inches. Where a narrow tire will dig in and bite and rarely slide because the amount of weight per square inch is much greater. Hence why on the 2002 Dodge the front axle is 4,440 pounds and the rear is 2,860 pounds. This means a single front tire is holding 2,220 pounds. now measure the patch of the tire and square inch and calculate the pound per square inches for the downward force. This is why with the 245's I'm not losing a bunch to width. This is why I opted for the 215's on the 1996 Dodge its even lighter truck and only 5,500 pounds roughly. So the weight on each tire is even lower this means I need even narrower tires to gain better winter tractor and push down through the water and slush.- ATF Oil Change. Service Manual Capacity Incorrect?

By chance do you have a extra deep pan installed?- Change to Limited Slip

One tire fire differential. No clutches. No limited slip. No locker. Just good 'ol differential with 80w-90 gear lube. Run most the winter in 2WD rarely do I lock in 4WD. I've got a brand new set of chains that are 15 years old and never used yet. Both truck are standard differential no clutches. The chains on the left are my set of chains from my 1972 Dodge Power Wagon which are nearly 30 years old rarely used. Now retired to the 1996 Dodge Pickup which I've never used chains on that truck yet. The chains on the right have never been on the ground yet are 15 years old. I've got to buy another set of rubber bands for those chains. The rubber bands have long gone rotten and broke. Again never used. I've carried a set of chains every year but never used them. I've never been stuck in the snow yet.- Rpm jump

Error codes? Have you tested your alternator for excessive AC noise? After your sure the alternator is good and clean power I suggest doing the W-T ground mod.- Vp44

Doesn't mean you got a good VP44. There is a lot of rebuilders out there and some don't have the Bosch 815 test stand to properly bench test and calibrate the PSG module on the VP44. Certified rebuilders are suppose to replace the PSG and then calibrate the PSG on the test stand for 3 hours and then the new PSG is flash with new code. Now the other rebuilders fly by night and just replace the worn parts internally and reuse the old PSG. This is why you have P1688 code because the PSG is damaged and was not replaced most likely. At this point in time, your pump is dead and requires replacement. The P1688 is a death code and this is a warranty issue for sure. Like I know Diesel Auto Power sells certified Bosch pumps from both Midwest Injection and Industrial Injection.- Fan only blows on high

Yeap the motor is failing soon. - HELP... 24 Valve rough idle when hot