Everything posted by Mopar1973Man

-

Flickering fog lamps?

Bad ground? Bad headlight switch? Bad relay?

-

ECM gone. What about VP

Possible fuel in the Raptor motor fouling the motor brushes.

-

AC blower motor somtimes not working

Strange... 3rd Gen body in a 2002... Now I've watch the video. Sorry about that. I was think 2002 2nd Gen body which I've done a bunch. Then my last comments was like the other 2002 3rd Gen here in the valley he smoked the blower motor brushes. Replaced that and problem was gone.

-

AC blower motor somtimes not working

Then the brushes in the blower are most likely worn out and barely touching.

-

Quadzilla Adrenaline Economy and MPG

In a nutshell as you make changes to the tune watch the engine load number more so. As you get closer to your optimal mark your engine load number will go down for the same speed. Might not be much but every little bit counts. Just remember engine load translates into the amount of fuel being delivered to the engine. Little easier to look at that than the CANBus fuel number which is the very same number but from zero to 4,095. The biggest thing against you is the tires. I'm going to assume you have 3.55 gears. Basically, you've got a final gear ratio of 3.27:1 to the ground if the axles are geared 3.55. Now if you had 4.10 gears and those tires you would be in the optimal mark for gearing at 3.78:1 almost a perfect 3.73 gear ratio.

-

AC blower motor somtimes not working

Blower resistor is failed You need to replace both the blower motor and the blower resistor as a package. Being the bearings in the blower motor is most likely partially seized up and the blower resistor quit or failing because the extra amperage draw is causing excessive heat on the resistor.

-

Quadzilla Adrenaline Economy and MPG

Weird how small of a gap for 7x0.0095 vs 7x0.013... Strange.

-

Quadzilla Adrenaline Economy and MPG

Ill try that last time it was resetting if I left it off on both. Again this need a bit UI/UX tweaking. Should be just a reset button.

-

Miss at idle

Yeap... Sad but true.

-

Miss at idle

Yeah, they are leaking. Most likely the crossover tubes are bleeding pressure past into the return rail.

-

Miss at idle

Might have to loosen the lines really good and try lifting the injectors a little to make them move again. I know they won't lift but if they are bound up they may not move to seat.

-

Quadzilla Adrenaline Economy and MPG

The switch remains ON but toggle off and then back ON. I'm at 140% for my 7 x 0.0085 injectors I might be a bit too high though. So you slide the toolbar back down correct? Then the Red X still there?

-

Quadzilla Adrenaline Economy and MPG

I realize that but the fact I just tapped on it and then closed it without making a setting then it locked up the app and would not connect till I set it for 0 or 1, "null" is not a valid value. Then the App will connect again. Just be aware its an issue that can cause someone connection problems.

-

Quadzilla display project

Ummm... The last ticket I've ever got was back 26 years ago. Been awhile since I've really been pulled over and picked on. I've had one a year ago but local cops don't bother with me once I pull my Idaho County ID for search and rescue. But the suction cup idea is something to be aware of. Even my Garmin and it constantly falling off the glass and laying in the bottom of the dash. Scares the crap out you at night when it does fall.

-

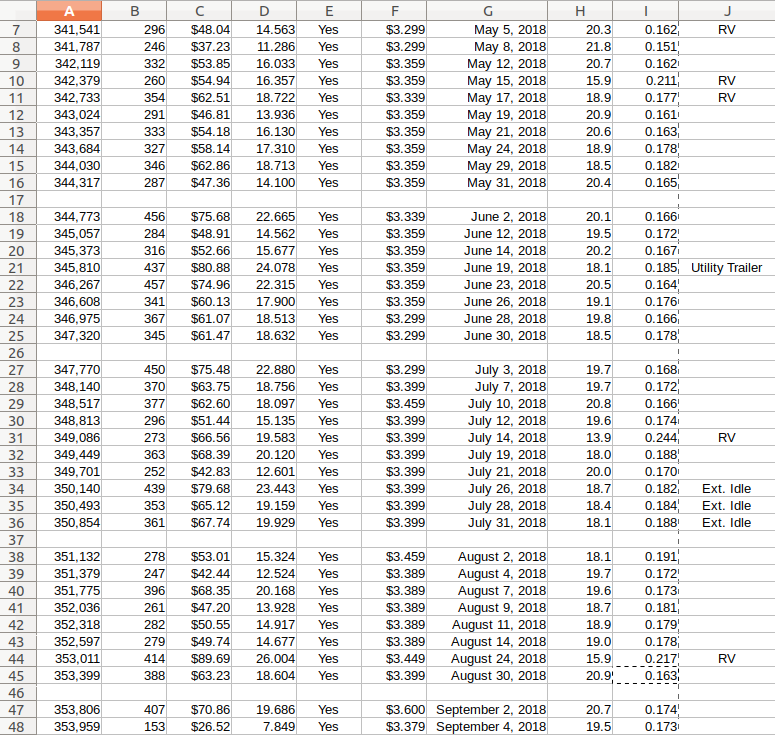

Quadzilla Adrenaline Economy and MPG

Let me catch up here... Ok I just did the latest update and flip back over to the V2 Quadzilla Only profile. After moving all my setting over by hand. Import issues from last time. I did run into a small issue that needs to be looked into. I manage to tap on the MPG reset option and the setting open and it of course is blank. Option of 0 or 1 allowed. I just closed the option and the app crashed. it needs a check for a valid variable before allowing to close. Still to this day I still have a random issue with getting the display started sometimes having to stop the truck, shutdown completely, shutdown the app, start the App, now start the truck again. Other than that it just tries once to connect and remain disconnected forever. Never tries again unless you do the full shutdown. So I'm up and running with the latest flash and set up on the Quadzilla V2 only tune. Let's see how the numbers stack this go around. As for fuel logs... I updated... As for the Sep. 2nd that was when I installed a 180*F thermostat. Then Sept 4th I just changed from 235's tires to 245's tires. Used Chris O's tool to adjust the ABS module for proper revs per mile. Verified to the GPS. I'm ready, guns are loaded...

-

Quadzilla display project

I've got a suction cup Garmin GPS and hate that dang thing it falls off the glass quite often. I've got it tucked quite low on the glass so it's not noticed by law enforcement.

-

Quadzilla display project

Another thing to be aware of... Just be aware of the suction cup laws for windshield mounting. Make sure there is other options for mounting the screen. https://blog.proclipusa.com/suction-cup-windshield-mounts/ States in Which Suction Cup Windshield Mounts Are Illegal Alabama Colorado Connecticut Delaware Georgia Idaho Illinois Louisiana Maine Montana Nebraska New Jersey New Mexico New York North Dakota Oklahoma Oregon Virginia Washington Washington, D.C. West Virginia

-

My dually

Looking closely at the body lines the look about right the illusion appears to be the skirt being crush slightly along the bottom edge of the bed that makes it look that way.

-

Oddball 24V DTC's active.

Now you might want to look into doing the @W-T ground wire mod to protect your ECM from future damage.

-

Oil Pressure and oil type

Like an old TDR article... Designed at the time of the release of CJ-4 oils. TDR57_Oil.pdf Then if you ask @cajflynn about oil changes on his 1.3 MILLION mile truck 2001 Dodge he was doing 20k oil changes. Hauling heavy boats. Then ask @dorkweed about his 84k oil change on nothing more than WalMart SuperTech 15w-40. There more to it with the filters he was running at the time and Blackstone testing. This is why I tend to disregard the short Schedule "B" because so few people actually fit that short change interval. Every winter here drops to -30*F at least. Every time I get to Ontario OR is nothing but stop and go driving. I've been known to idle the engine up to 3 hours with heat or A/C on to keep comfortable. I'm not going to fry or freeze. Every time I leave the pavement is a dirt road. Heck, my driveway is a dirt road. EXCLUDED - all my trips are over 100 miles typically. Typically I can put down 250-300 miles per day. Then every time I was on the interstate (85 MPH) heading to Boise, ID this summer. temps in the 105 to 110 realm. Just towed my RV trailer to Ontario last week. I work for the local fire dept so every time I get a page I can and have jumped in the seat and ran. No warm up. (Rattlesnake fire, ID) Every time I go get firewood and down in the southern Idaho area is nothing but desert. I'm still not going to change oil every 3,750k. So looking at @cajflynn that was doing hotshot work and hauling heavy boats should been changing oil every 3 to 4 days then. Myself I would be changing oil every 12 days that would increase the cost operation considerably. So in one year I would have to change 17 times vs 8 times on the Schedule A

-

Up yet?

@MoparMom said to tell you Dave that she is not getting up for something that ugly. As for me... I'm nearly done with my 2nd cup of liquid jump starting.

-

Oil Pressure and oil type

Very few people fit the schedule"B" realm.

-

Fuel shut off

Basically, the solenoid is internally shorted out. You'll have to replace it.

-

ECM gone. What about VP

I would have the ECM rebuilt. Is that Raptor on a relay? Or is it a DDRP Raptor?

-

Oil Pressure and oil type

Way too early. Right out of the owners manual is 7.5k miles. Even my 1996 Dodge 1500 is 6k miles on an oil change.