Everything posted by Dieselfuture

-

High Idle Switch install

So in other words for performance tunes shut it off back to iat ? Or not necessarily

-

New Member

I'm sorry to hear that about your other half Tom, I'm afraid most of us are in same boat, (or at least me lol) they all gone nuts for the most part, brainwashed by tell-lie-vision, thinking they need a new house,car, image, and everything else all at the same time, and who cares if it's all bought with borrowed money. Life is not what it seems that's for sure. But I believe our creator has a plan for it all.

-

Dodge Off-road LLC

- Dodge Off-road LLC

I've done it on off road stuff I had. Makes it flex more and softer ride but usually takes away from how much you can load in back, adding air bags would fix that. Also I'm not sure on kits for these trucks but the ones I made change pinion angle and lift the tuck slightly too.- Sucking air at hard pulls

It's probably not sucking air it could be the issue some have with too much pressure in cylinders on high boost situation and letting off to fast causes pressure to be injected back through the injectors. What's weird is you say it does it when you let off slowly it's usually the opposite. I may be way off here too, just a thought.- Brake Boost

If that's the case with leaky seals then before changing them make sure vent isn't plugged. I check all my vents early just to be sure.- High amp alternator

I can't help but wonder what if this grounding thing with the alternator bracket has anything to do with head gasket failure that most experience by thermostat housing. Maybe there is a connection there, electrolysis or something along those lines- Fuel pressure gauge

I'd use both if you have them both, or if just one I'd go with needle valve, mine is barely cracked open.- High amp alternator

Another awesome article, thank you. I did notice some galvanic corrosion on my bracket last time I had alternator removed. I cleaned everything and used dielectric grease which is probably not the best choice when you trying to make connection better not worse. That brings another question, this ox-gard used for electrical connections, is it conductive or non-conductive, because if it's conductive you would only want to use it on a single connection not a multi plug. My intention with dielectric grease is to tip corrosion away, and if the surface is clean it will still make a great contact. Just thinking out loud here.- Dodge Off-road LLC

One year..... man you are patient, I'd start going nuts after few weeks lol.- Turbo/Injectors for Heavy towing

I have a BD bolt to turbo with new flange 5 bolts style, if you're not planning on anything crazy for turbo it's a good set up, but you can also get an in line one that is 4" vs 3" that I'm using. In line will let you do a lot more in long run.- Turbo/Injectors for Heavy towing

Nothing most of us haven't dealt with it's all about how willing you are. Lots of info here to get going. On the other hand I had a turbo built buy http://www.northamericanturbo.com from hx35/40 and some other turbo parts, 62/68/12 And using 75 hp injectors I'm pretty happy, direct bolt in. if you call them talk to Zack and tell him your goals, I didn't even send my original turbo in kept it as a spare and paid I believe $100 for a core. I have less than thousand bucks in mine with the core. Quad with v2 is a way to go no matter what setup you choose. I'm glad @jlbayes recommended Zack as I was lost on what turbo to go with, all I knew is I wanted 60 or 62 compressor wheel and didn't want to spend over a thousand bucks, my other dilemma is that I have an exhaust brake and had to have a turbo that would still work with it. Side note, Zack told me they only use genuine parts no Chinese junk, but they do work on any kind of Turbo including Chinese junk, he said it was hit-or-miss with China stuff.- Trying to find a compressor wheel

Try these guys, they built my turbo. I'm happy. http://www.northamericanturbo.com/- Poor Fuel Mileage and Low Power

With that said when you got your obdlink did you set it up for year of your truck, I used mine a few times but I just skipped that step- Head bolts

If no codes my guess is injectors or ac noise.- injectors

My bad, I could of swore last time I checked it didn't but that was 5 years ago.- Head bolts

I would not mess with them, you just going to open up a new can of worms. If you're going to move them at all just put studs in one at a time or leave it alone.- Custom Quadzilla Tuning R & D Thread

It looks like you're completely losing your canbus fuel and everything else follows, unless I'm looking at it wrong- Custom Quadzilla Tuning R & D Thread

I've used 1500 paper and my fingers on the line with good results, just pay attention and be patient. And make sure you give it time to stop leaking as some fuel is left behind the nut that screws in head and with heat from head fuel will come out pass threads, that's why if you don't have hard starts (I don't think my truck makes a full revolution before it fires up) leave it be for few days. Or something is cracked, like tip of the line.- Construction Job Stories any Job Subject for that matter....

It's amazing what human body can take and adopt to. But not all....- New turbo help tuning

I think he meant to say 40 for boost scaling, not tps pump minimum. I think you can actually try 36-38 to get it more aggressive.- Flat bed

I have not yet, but been thinking about it, it may be in my future builds but probably not very soon, my box would have to rust away first, at the rate it's been going I might be looking at 7-10 years unless I get time and get my welder set up for SS and be very board. Yes my new box will be SS and have all sorts of goodies on it. I've been looking at random pictures on Google to combine ideas. It may even be a dump box too. But first I got to brainwash my wife to want to move out in country with a big shop and ...... a flower garden should do it maybe with some tomatos and bla bla bla...- Construction Job Stories any Job Subject for that matter....

@dripley what is it supposed to be in your picture? One time I remodeled a house that had some asbestos and called the dump, they told me just let us know when you get there, which I did and they had me back up to a hole they dug at dump, as son as I dumped my load it was buried and no questions asked, no extra fees. they just wanted to make sure it was under dirt right away way.- alternator

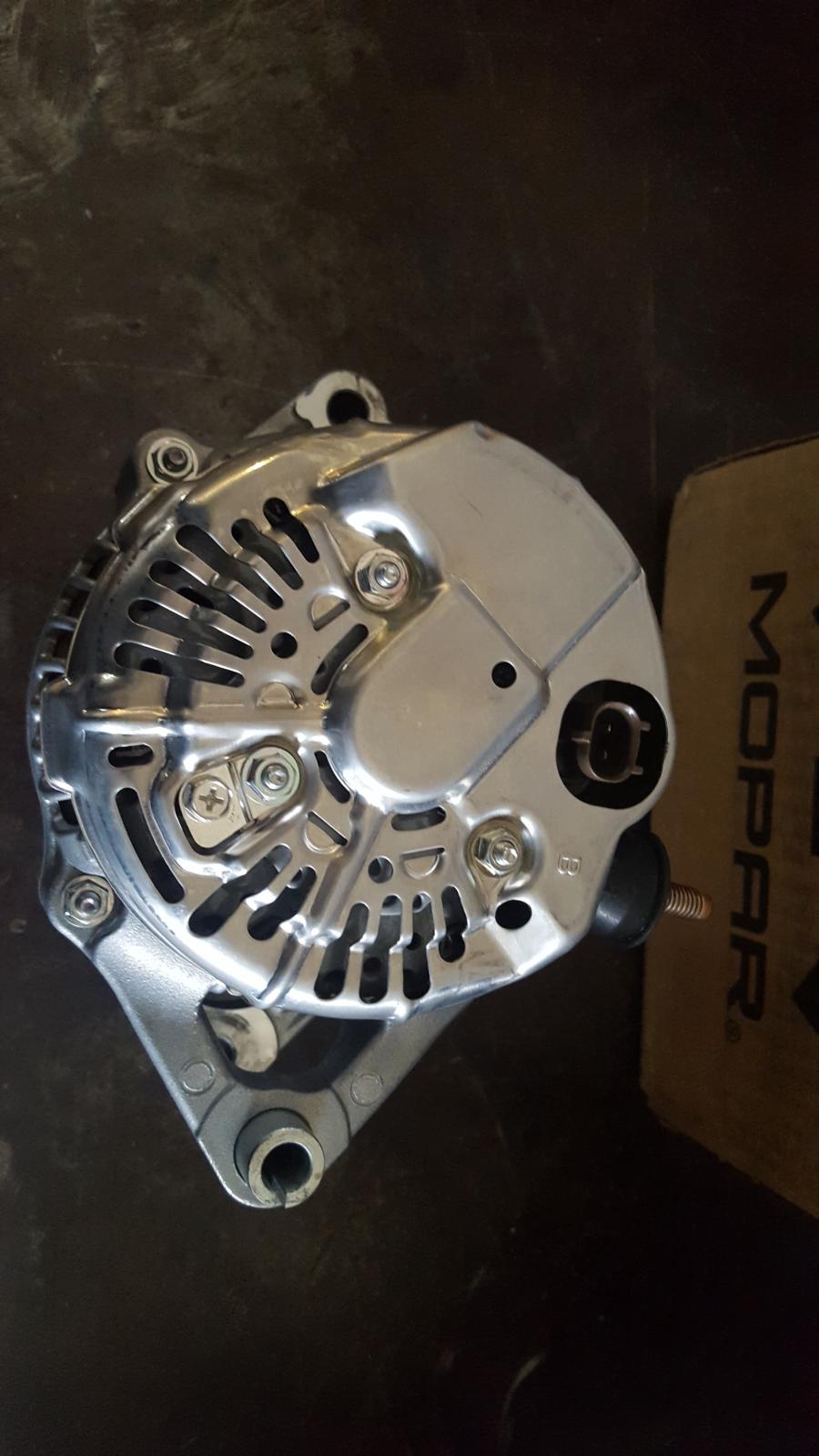

For Boosh I got parts at local alternator/starter rebuilder shop. I also found parts on line but can't remember now where. Yes denso bolted right up to my truck.- alternator

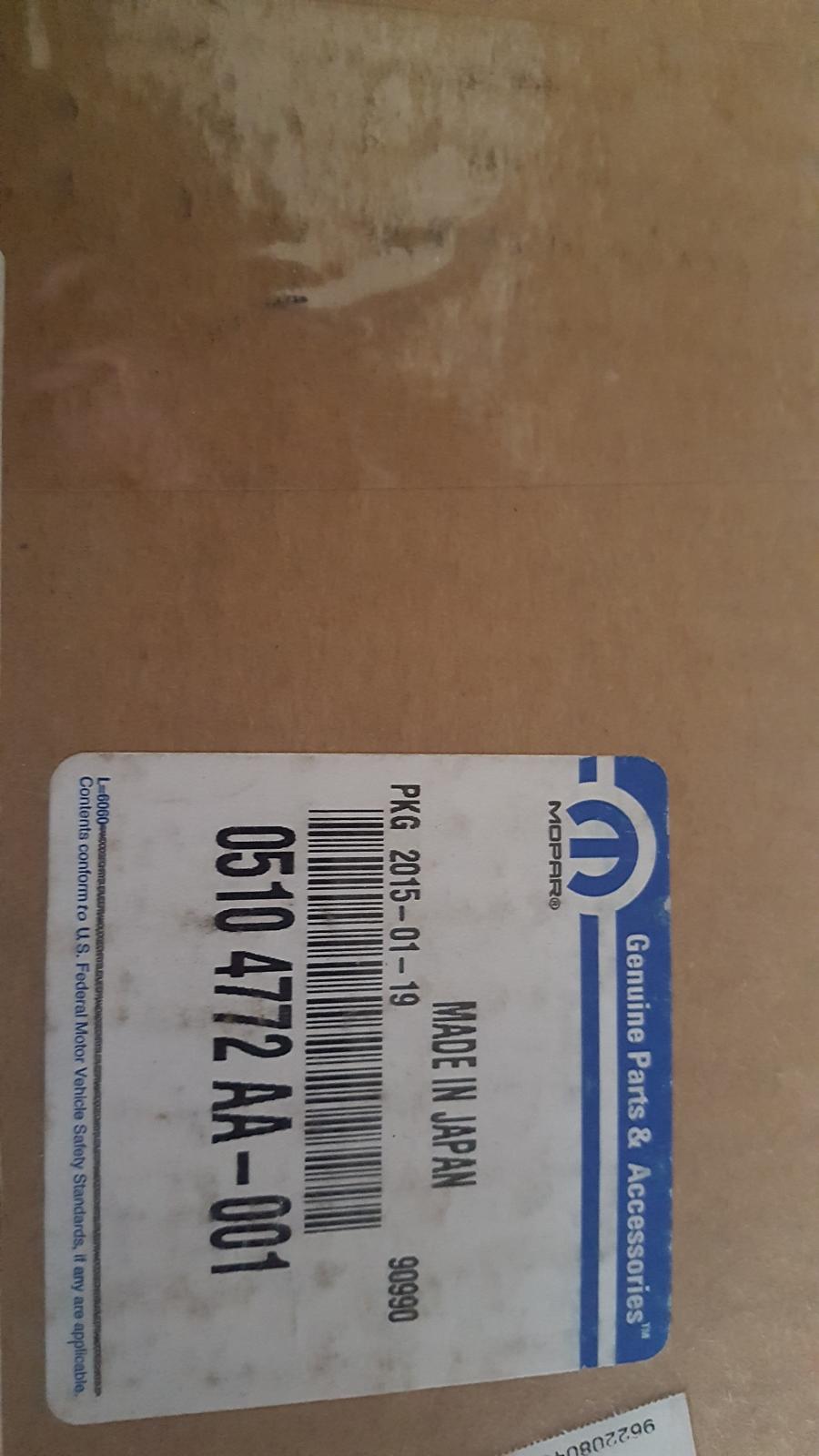

.24 is too much, I can get close to .08 with accessories on and truck reved up to 2500rpm which is pushing it. Denso will fit just fine at least on my 02 it does, I got it when I was having problems with my Bosch used it for few weeks and then I rebuild my Bosch and put it back on so now it's a spear. Denso out of box was around. 05 but after driving with it it came down to. 03, I'm guessing brushes had to wear in. Here is a denso I got on line from some Mopar discount site, can't remember which one now, seems there are several selling same thing. Keep in mind my truck is early 02. - Dodge Off-road LLC