Everything posted by Mopar1973Man

-

BHAF

So far most all performance air filters I've seen either dry media, washable, oiled, etc. They all seem to be a dirtier filter. What good is it to have a better flowing filter that flows more dirt than a slightly more restrictive filter that is way oversized for the job and doesn't pass dirt like the performance filters do...

-

Electric Water Heater Issues.. Again..

Basic...Go back to your breaker panel and convert the water heater over to 120 VAC from a 240 VAC breaker. Make sure the breaker is proper size for the elements being used. Then at the water heater you need to be sure you feed is 120V. (Don't test this with the water heat hooked up till your sure of your wiring.) Now your going to have to double check the wiring lay out inside the water heater... But at that point I just screwed in my 1,100w elements and set my temp and kick the breaker on. Double checked again for proper voltage at the elements. DANGER! 120/240 VAC is very dangerous voltage to work with. If you not sure of what you up against I would suggest getting electrician to do the work.DISCLAIMER: I'm not responsible for any damages, house fires, or electrocution...

-

Abs and brake lights are on

Most likely what I've got right now. I've got a failed driver side sensor I can physically see the damaged lead. So I would consider replacing the sensors up front if the speedometer is still functional. Here is the full article... http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/23-brake-system/29-antilock-braking-system-abs

-

Steering Wander?

I've done this adjustment on several vehicles and had good response from the adjustment. Just do little adjustment at a time... Test and repeat. Don't get carried away with the adjustment.

-

Electric Water Heater Issues.. Again..

Since I'm on a limited power supply I've converted my 50 gallon water heater to 110 VAC 1,100 Watt elements. Man you want to talk about hot water it still getting piping hot and uses way less power and water heater seem to last a long time too. Being the water is heated slower and not going through sudden changes of temperature so the glass liner isn't getting cracked / damaged.

-

Fuel tank is building pressure?

Being its a 12V there isn't any way for compression gases to get back to the fuel tank. Like on the 24V since the injectors are in the top of the head and the return rail is part of the head you could have combustion gases leak back into the return rail from a bad copper shim. But this isn't possible on a 12V.

-

starting trouble when hot

First off... Welcome to the family...Second off I need to know what you cranking fuel pressure is like. It might be the fuel pressure is just way too high during starting.

-

problems with WTS/IAT/ECM

Either pay the dealer shop rate to do the test or pull them out and have them test it your choice of shops. Some guys like using rail caps and cap off one line at a time and see if the starting issue goes away. But if its more than one injector its going to be tough to test this method which return back to pulling all and bench testing.Common rail injectors are known for having a issue with building rail pressure after the injectors got wore down.

-

I may have hurt a cylinder!

Now I'm curious what those 2 sets of rings look like? Kind of looks like a debris issue...

-

Torque Converter Lock / Unlock Issues

PASSING Grade! :thumbup2:Also come to my attention that cheap DVM's tend to report this 30 volt level. Where a high quality Fluke or similar with report proper voltage.

-

BHAF

I need to add that picture to the BHAF article...

-

01 6 spd Vs. 01 5spd

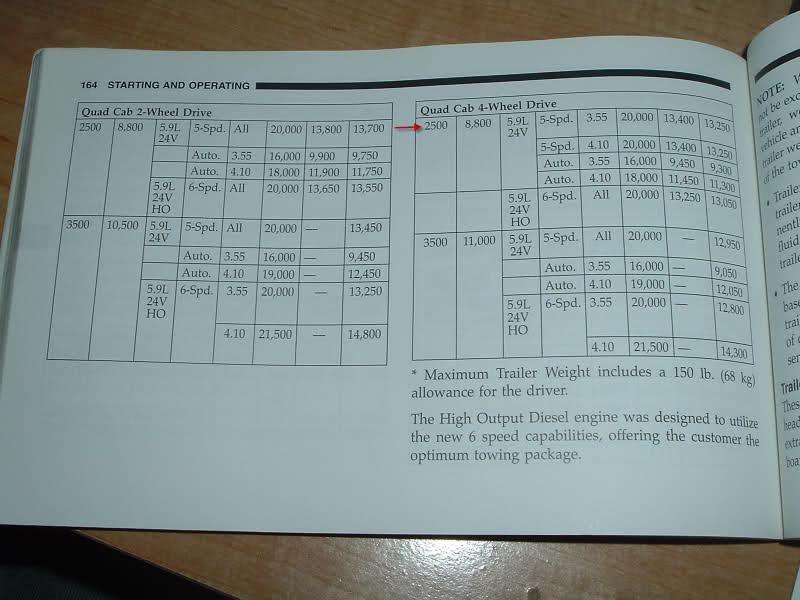

Protect the 47RE... Even look at the tow weight limits... The 5 or 6 speed manual were allowed much more weight.

-

PCM difference between 96 and 97??

I don't see any reason there would be a difference. All the PCM controls is the cruise control, transmission and alternator. So why would you change the PCM?

-

27rls cougar

Bit of simple math. 12 VDC x 250 Amps DC = 3,000w = 120 VAC x 25 Amp AC 12 VDC x 120 Amps DC = 1,440w (Stock alternator) You would need at least 3 alternators to power the AC unit on the RV. Not happening. There is a reason I didn't use 14 Volt for the calculation too. The reason being to show 12 / 120 relationship. So now you know to take any household appliance and add a zero to the Amps and you got your 12 VDC amp draw... Remember my house is ran on batteries... So you left with a portable generator. I've got 2 for the RV. I'll admit the small 2,500w I got is extremely quiet and capable of recharging the batteries and running the fridge but it will not start the A/C nor run the water heater. Just doesn't have the strength to hold the load with it tiny engine. But now I've got a construction grade 4kw generator that powers everything all at once on the RV without blinking an eye. But the sad part is it takes 2 people to pick that beast up and it loud.

-

rebuilding NV 4500

Hmmm... It might just be time to consider a oil temp gauge and two sensors. :think:1 Rear Diff1 TransWith a bit a switch magic have all in one gauge.

-

Rams-O-Plenty

Come to Idaho... we got those critters wondering around Hell's Canyon... But rare to see one. I'll admit that is a killer picture...

-

BHAF

No. Like the video shown a few post back the outlet of the turbo is going to be 300-400*F before the intercooler regardless of the input temperature. So the intercooler is more important than worry about a cold air intake. Like ISX said back at... http://forum.mopar1973man.com/threads/6736-BHAF?p=69498#post69498 No. You can add a piece of 4" exhaust pipe in the neck to stiffen the plastic up more. But in all the miles of using a BHAF still no issues with it popping off.

-

Vacuum pump seal

Hua? Disconnect all the power steering lines from the power steering pump. Disconnect the oil line ans the vacuum line. Pull any brackets holding the power steering pump. Pull 2 bolts on the gear case. Remove and rebuild. Re-assemble in reverse order.

-

What fuel pressure do you run if you have a gauge?

With 30K miles on the AirDog filters I'm now down roughly 1.5 to 2 PSI from my 19 @ idle to 17 @ WOT. It's hard to tell exactly because of the cold fuel is lower in pressure anyways.

-

Torque Converter Lock / Unlock Issues

Here are my 2 most up to date videos...

-

Do it yourself steering work

Not to bad really. Either use a pickle fork or a BFH to get the tapper shaft released. No, I don't hit the nut or threads but the knuckle where the ball stud passes through. After changing them I usually rig up a pair of 4 foot 2x4 to the tires and measure the front and rear toe to get it at least close then take it to a shop and have it aligned. It might be just smarter to skip all this and have the shop install and align it in one shot.

-

First time Cummins owner from Bay Area

Shoot that's a clean truck. Time to get that beast out and work with it. :wink:Welcome to the family.

-

New here.

I would be out of job. http://www.linkedin.com/in/mopar1973man

-

New here.

Welcome to the family...

-

rebuilding NV 4500

Most people tow way too fast too... Just because it can doesn't mean its going to hold up.