Everything posted by Mopar1973Man

-

Injector install questions

HX35W will be a bit better upgrade. Spools just a bit slower but can handle a good solid 35 PSI without much issues. You can push 40 PSI but it gets hot on the EGT's side. OK for sprinting.

-

Can’t stop the ac noise

I'm just trying to find your source of the noise. If the alternator is removed then the noise should drop to ZERO or nearly. If so that just proves the alternator is still having issues. If you measure at the batteries and still have noise now we have to start digging to the source of the noise. Bench testing the alternator is another good way to verify too. Just make sure they can measure AC ripple voltage.

-

Smarty s03 today :)

- Quadzilla model xz2002-u question

@Me78569 Wouldn't the xz2002 number be the year it's designed for? 98.5 wouldn't work with a 2002 box.- 2004 Cummins ABS Code 84 VIN Mismatch Issue.....

You could try Module Masters in Moscow, ID they do ABS module repairs and programming. https://modulemaster.com/rebuilds/ Then you could try Auto Computer Specialist in Florida they also do module repairs and flashing. https://autocomputerspecialist.com/- Can’t stop the ac noise

Check the voltage at the battery. If it dropped the alternator still the cause. That is a good second test too. No. The speed sensor is only for the PCM for shift data.- Suggestions for Quadzilla

This is pointed towards @Quadzilla Power for suggestions... Bluetooth connection problem needs to get fixed. Quadzilla is the only thing with serious connection problems. Bluetooth connection cycles once then stop trying to connect. Takes several tries to get a connection. Mobile device needs to remember last display used. Always have to swipe to the second screen. MPG data erased every key on cycle with 2.8.4 Firmware. MPG data not an option for the normal vehicle selection. ECM/Quadzilla fighting at low throttle (getting worse the better my economy tune gets - bucking) Need to add audio alarms to the Quadzilla (Cute female voice would be awesome! ) Tunes should not need to be exported to backed up. Should be able to save tunes to the internal storage of the device (I've got 256 GB!) Data logging should have to export either again should be an option to save to internal memory. (I've got 256 GB) Coolant alarm should be removed since drops to -40°F at 204°F. Hard to use if it doesn't have the data. Would be nice if both the app version and the Quadzilla firmware version were displayed in the control panel. Then people could tell if an update is needed. The biggest one that drive me nuts is the connection issue. Fighting with the Quadzilla start up, shut down, start up, shut down. Got to wait for the Quadzilla display could not connect message to do your restart. It only tries once then quits. Once it got a good connection going typically it continues but that rare 10% it can just miss and then tries once then quits even if I leave the phone in the truck set up. Bluetooth device should be saved as part of the settings and should have to be selected every single restart. Display thing is annoying too. Startup and have to swipe to the second screen. This should be remembered. Then the bucking. The more and more I get closer and closer to the optimal MPG number the engine load is getting less and less. It now to a point when cruising city streets you have constantly be accelerating or deal with the Quadzilla bucking pretty hard on the driveline. My typically 25 to 35 MPH engine load is now in the 5% to 11% which is below my idle engine load and bucking can get pretty bad some times. I know it the ECM and Quadzilla fighting because Level 0 doesn't do it at all.- Smarty s03 today :)

@pepsi71ocean like I've found out with 320 bar injectors you are coming up short on the timing. When the injectors are popped that high your cruise timing have to jump way up. I'm running now 23° to 25° worth of cruise timing and now just passing 21 MPG. Just no way a Smarty S-03 can get you the timing you need to gain full efficiency.- Can’t stop the ac noise

Unhook your alternator and test again. Might have replaced the diodes but the brushes, slip rings, etc can still cause issues. Then the output speed sensor on the transmission could cause shift issues too.- 2000 3500 no power,sucks fuel like it's free

Remember one thing... Boost does NOT create power. Excessive boost does nothing. FUEL makes power and the boost is created keeps the EGT's in check. Yes, you need a Quadzilla (or a tuner of some sort), then the boost elbow, and a good set of injectors (if you have 100k or more miles on yours).- 2000 3500 no power,sucks fuel like it's free

Meaningless without a tuner. If you can't boost fool then the fuel will be cut when the ECM see too much boost.- 2000 3500 no power,sucks fuel like it's free

Have the injectors removed and sent into DAP they can pin test the injector nozzles for size. There is no other way being that stock bodies might have aftermarket nozzles.- 2000 3500 no power,sucks fuel like it's free

Can't have both. Can be stock powered and expect lot of power towing.- ABS

Replace the sensors as a pair. Retest. If it's still there then replace the bearings as a pair. If one bearing is bad the other is close by to failure.- 2000 3500 no power,sucks fuel like it's free

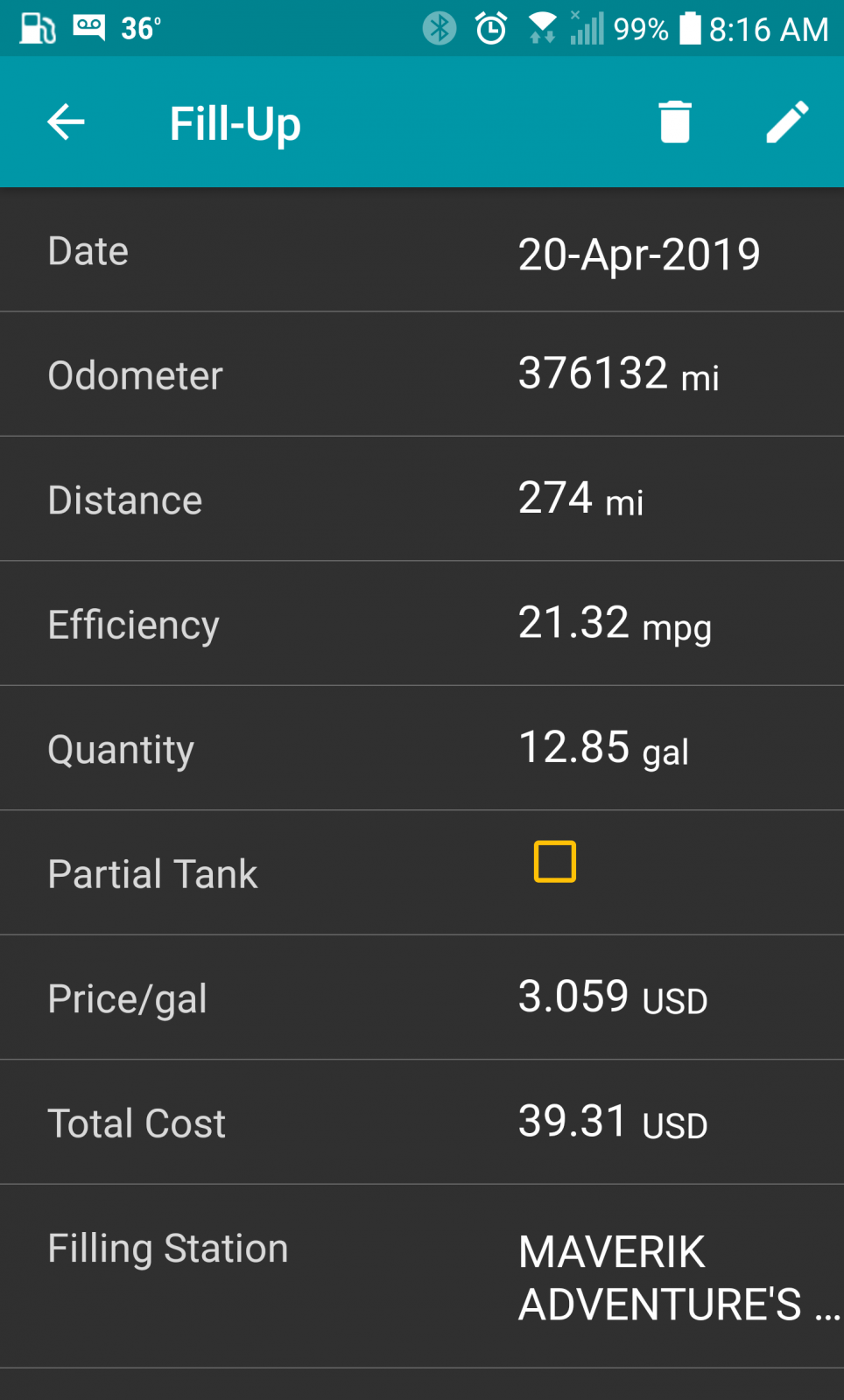

@Dieselfuture is right on the mark. With Dieselfuture... Quadzilla Adrenaline 7 x 0.010 Injectors @ 320 bar HX35/40 Hybrid (60/60/12) 4 Inch exhaust BHAF 13.68 MPG towing my RV - 31 foot Jayco Eagle @ 8,000 pounds. 21.32 MPG running empty Making roughly 500 HP to the ground.- 2000 3500 no power,sucks fuel like it's free

Reduce your MAX boost below 20 PSI. Stock ECM is restricted to below 20 PSI period above that fuel is cut deeply. This is totally normal for stock tune truck it's only 235 HP at the flywheel. Different story when you add a tuner now all those restrictions are removed and the sky is the limit for power. The other problem anything above 2,000 RPM typically is a loss for MPG's. 4.10 gears are too high of a ratio for highway travel. 3.55 with stock tires typically do better. Like myself I'm running the 245/75 R16 on 3.55 which produces final ratio to the ground of 3.69:1.- 2000 3500 no power,sucks fuel like it's free

Going into a defuel mode because of no tuner present. Once boost gets to 19 PSI the ECM starts cutting fuel. By 25 PSI it will be fully defueled and tripping P0234 code for over boost code. Boost has to stay below 19PSI for stock setup. You need to highly consider buying a Quadzilla. This would fix the boost problem it comes with a boost fooler and allows for fuel as far as you want to. Timing control to get MPG up better since the stock ECM is retarded in timing pretty good.- Vibration after Southbend Dual Disc Clutch installed

Typically this what happens people swap to thinner fluids and gain a bit of time before it all goes bad. Yeah, 6 speeds (NV5600) are not cheap to fix either. Nearly 2 times the price of a 5 speed (NV4500) to rebuild. Like mine was $1,800 to rebuild new bearing, synchros and 5th gear replaced, and a main shaft. The reason 6 speed is so expensive is not really many building parts and really kind of tough to get.- Vibration after Southbend Dual Disc Clutch installed

Personally, I think all of it is too thin. Even the factory fluids. When shift quality goes down people opt for thinner fluids then the wear sets in faster. Like I found out the factory 75w 85 for the NV4500 isn't enough and I ate the 5th gear hard facing off. The gear was replaced but it proved to me that factory fluids don't protect good enough. Thinner the fluid better the shift quality this why the dealer is now filling both NV4500 and NV5600 with ATF+4 just like the G56 transmission. Shift quality is great but the protection of the gears and parts is really poor. Pennzoil SyncroMech fluid is technically a GL-4 fluid but doesn't make the rating because it's too thin to make the full GL-4 rating. Again here we are with thin fluids. The gearbox is going to generate heat the fluid has to protect the gears and bearing. If the heat gets too much the fluid gets to thin and it starts creating wear. Kind of like why we don't run 0w 20 engine oil it would get to thin to protect the moving parts of the engine. But it would have the least amount of drag and produce the most power. Same thing with a gearbox it needs to be thick enough to protect the parts and synchros.- Vibration after Southbend Dual Disc Clutch installed

Most likely the gear lube was too thin. Couldn't protect the synchros. With the dual disc clutch, there is a lot more mass spinning and the synchros have to sync the input and output speeds and since the fluid is then by factory specs and the added mass most likely ate the synchros. The other possible problem is the dual disc is having issues and dragging the input a bit too much and causing the grind and shift problems.- 57/65/14 with 7x.012s

Like my Hybrid HX35/40 is a 60/60/12 which is nearly like the HE351 which is 60/60/9. Ok, turbo still just a bit small but OK for 450 HP range for sure.- 2000 3500 no power,sucks fuel like it's free

185K miles your injector are most likely shot. You'll need to pop test and consider a replacement. Then stock tune ECM is rather deeply retarded in timing if your towing. It will eat the fuel like no tomorrow. Good set of injectors and tuner would do you more good. You don't have to go wild either. 4.10 gears and stock tire size is going to be awfully low geared and limit your high way speeds below 65 MPH.- P1693 with NO companion code

You better have a wire that is less than 0.006 to fit in the cross over tube. The purpose of the cross over to is to contain the edge filter with is a tapper plug that necks down to smaller than the nozzle holes of the stock injector so small object are hammered by the pulses till they are small enough to pass thru the injector.- Need help with download

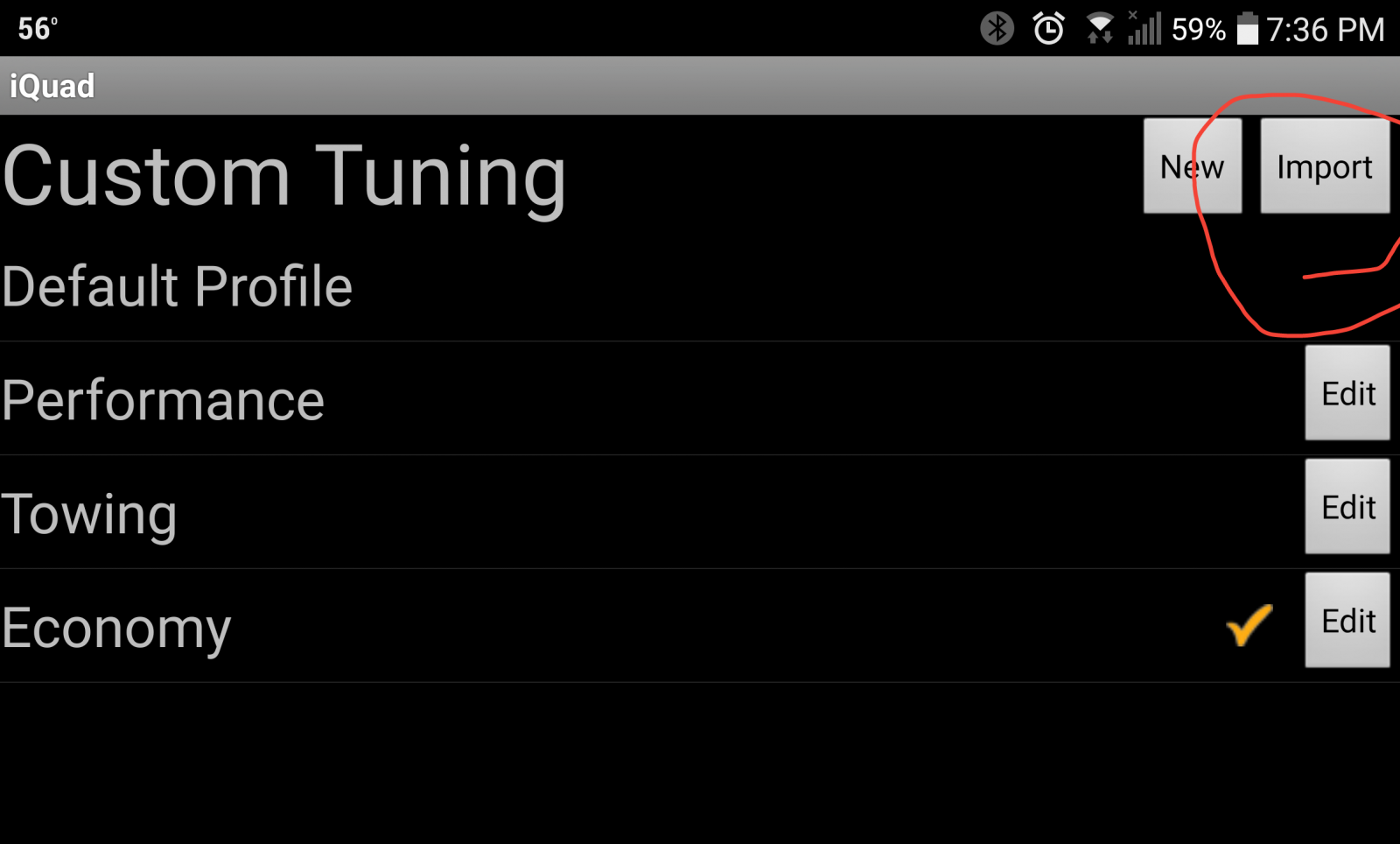

That is done on the mobile device. The import button is in the upper right of the Custom Tune Screen.- Project finished.

Be careful... If done wrong you can change the thrust angle of the truck causing it to pull to one side or another. I would suggest having an alignment shop do this and ask for more caster angle added. - Quadzilla model xz2002-u question