Everything posted by Mopar1973Man

-

Headlight upgrades

I just requested the D2S headlights. If you want you can call him and talk to him directly and he'll make anything you wish.

-

Quadzilla Adrenaline shut down while driving

Other than the random times where the screen stops updating. Rare but has happened.

-

High idle problem

Remember what I said. As long as the IVS trigger the ILDING lead the ECM IGNORES the APPS voltage and signal and uses its own idle software. So basically switch number one would be grounded and switch number 2 would be open or showing +5V on the ECM. This tells the ECM to IGNORE the APPS voltage use it idle software which high idle software is part of.

-

Quadzilla Adrenaline shut down while driving

I've seen this bug as well randomly too. Didn't realize the Quadzilla shut down. Typically I run cruise control and wouldn't notice it dropping out but I have noticed that the screen locked up and no longer updating the values. Thinking of that I still have that weird connection problem still where you fire it up and does NOTHING just displays the screen and doesn't even hook up to the bluetooth. About 4 to 5 startup and force shut downs to get it going. Maybe related???

-

Arduino climate control

I'll have to go look at the winch relay system on my ATV. I'm using two 30 Amp relays for that with a single switch. 12V power from the battery. The two relay is capable of forward and reverse actions on the winch so basically, you just need to duplicate that.

-

Tyler's 4th Gen

I heard a rumor that the next generation of Cummin engines will not use DEF. This is all still rumor but I'm hopeful.

-

Happy Thanksgiving

Since October 2, 2016. I've started the trips back and forth Jan. 5th 2017. https://mopar1973man.com/topic/11942-prayers-please/?tab=comments#comment-144138

-

Happy Thanksgiving

Thank you. It's not an easy life. Do most of this work solo without help. After a while, you learn your own tricks of handling a big job like this one without getting hurt or worn out. My biggest factor is time. Being I'm still taking care of @MoparMom and getting her back and forth to dialysis treatments. Basically 13 hours every Tuesday, Thursday, Saturday I'm on the road driving from New Meadows, ID to Ontario, OR (250 mile round trip).

-

Happy Thanksgiving

Heck, it started with a low of 49* and got to a high of 62*F here today. Average wind speed of 6 MPH. Really nice out. Off and on misty rain showers. Typically the ski resort in McCall is open for skiing by now typically. https://brundage.com/on-the-mountain/winter/snow-report/ Stacking on the trailer and the tarp it so it can dry out. I've got some dry wood in the shed but I don't want to bury my dry wood with the wet or damp stuff I just split.

-

Happy Thanksgiving

Here is what I've been doing... Splitting firewood, burning off my garbage pile. Funny how soaking wet bark will burn just fine with nearly 5 gallons of oil poured on the pile. That also got rid of an oil change and half for me. Nice to have the wood splitter hooked to the ATV and I dont have to pack the firewood. Then the plow blade in front will be handy later on to push the trash pile back in the fire more.

-

Track Bar

Track Bar... This will be my second failure in a total of 324k miles. My last track bar lasted over 100k miles. I will admit I screwed up this time. Being I'm doing all the back and forth trips I opted to just at the local AutoZone and pick up a trackbar. $90 buck with a lifetime guarantee. Didn't realize it a sealed unit that has no grease zerk. I found this out after I've already pulled mine out and need my truck. My last Track Bar was a NAPA unit and it did very well to go 100k miles. Just times are tight for me and had to take what was available. I do plan on getting a Luke's Links and rebuilding my old bar since its got the small non-Moog head and can be done. So when this lifetime warranty non-greaseable AutoZone track bar fails I'll have a rebuilt unit here ready to go.

-

High idle problem

Basically you need to make sure the APPS sensor is tripping the IVS (Idle Validation Switch) for IDLE MODE. Make sure you have backed off far enough and it should be in the idle zone of the contacts.

-

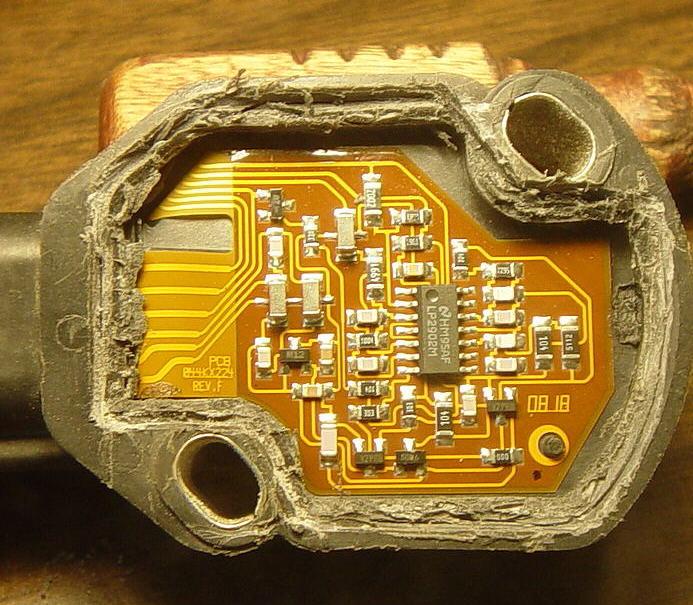

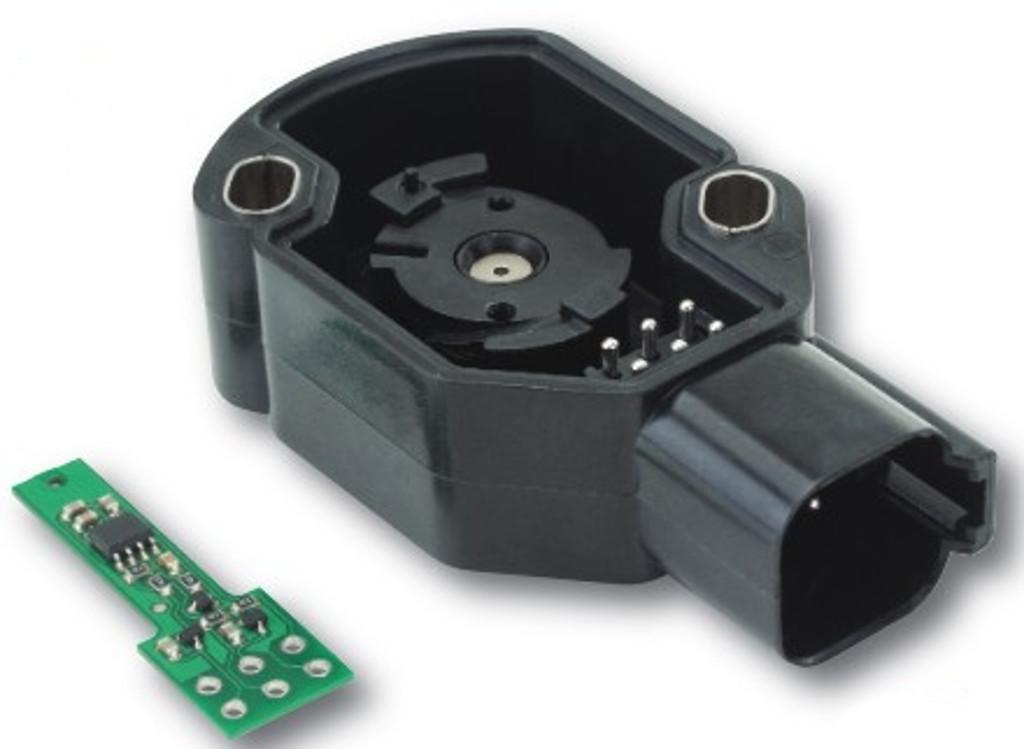

New APPS, reset now P0222 error?

Timbo's APPS has no electronics. It completely mechanical. Where the OEM and Wells APPS have electronics to handle the logics of the IVS (Idle Validation Switches). Timbos APPS Wells APPS OEM APPS... Voltage doesn't matter to the ECM. Voltage matters to the APPS. So like OEM the voltage on the tag is typically 0.5xx Volts. When the voltage rises above the tag voltage the APPS flip-flops the grounds signal to the ECM tell the ECM to pay attention to the voltage for throttle information. When it drop below the IVS flip-flops again and ground is signal for idle mode and the ECM IGNORES the APPS voltage and uses strictly on board idle software. So with your case basically both IVS signal lines are shorted to ground and the ECM doesn't know if your throttling or idling. So now back to Timbo's APPS the whole voltage thing is obsolete because its no longer used. The IVS is based on bellcrank ANGLE not voltage. So APPS voltage has no bearing on if the ECM see idle or not.

-

Morimoto HIDs Headlights in a 2nd Generation Dodge

Aren't Halo's considered daytime running lights? You might check your local laws.

-

Grid heater manual control...

Optimally... I would figure out the resistance the ECM needs to think there is solenoid in the system. Then you could wire up a toggle switch so the ECM sees the needed load to be happy but the solenoids are disconnected. This wouldn't require any heavy duty switch or relay then. Or you could buy a single grid heater relay and hook it up before the OEM one in the power lead and use a toggle switch for that one to connect and disconnect the power.

-

Question about IQUAD gauges with my phone.

PM sent to you...

-

Happy Thanksgiving

No Thanksgiving here... We are going to enjoy our quiet 4 days to ourselves. I'll be working on the truck doing basic repairs. At least it 3 days without having to travel.

-

Alternator Question

Hmmm let me ask around if we can get Bosch diodes.

-

Morimoto HIDs Headlights in a 2nd Generation Dodge

For the bumper method and a 1/2" impact gun doesn't take much.

-

Quadzilla Adrenaline Economy and MPG

Actually you might attempt 25%... You need to find the closest boundary to cruise to power mode. I was finding my truck was still in cruise mode and climbing grades. Now kicking the cruise limit down to 25% now it kick out just about the time start climbing hills. I resumes cruise timing in timely fashion. This is based on 55-65 MPH speeds.

-

Edge Juice

There are only two things that cause dead pedal... 1. APPS sensor. Typically there is a P0121, P0122 or P0123 code with the dead pedal. 2. VP44. It could produce dead pedal like problems too but doesn't have to throw codes. Now without read back over the entire thread did you ever do a AC noise test?

-

App permanently crashing after gallon trip calibration

That's the only thing I can see that is going wrong. @kzimmer is changing from 150 to 158.84 that would be the only thing I could see that might create a hang. @kzimmer I would try the new copy with just 158 and see if it passes.

-

Floor Board leak

The HVAC drain is a common issue and lot of people just extend the drain with some vinyl tubing and the problem is gone. Like in my case you can visibly see the dripping water in the middle of the floor mat and coming from up behind the glove box.

-

App permanently crashing after gallon trip calibration

The only thing I could think of is dumping the app and reinstall the app again... Yeah, the changes will be gone but at least you'll get back to working. I would for sure hook up with @Me78569 report this bug so it can be repaired. You might also just load up a fresh copy and just do the calibration again and see if the decimal is the problem.

-

Denso Alternator Diodes and Brush Pack Replacement

Thank you for the write up. This will help the folks change diodes in their alternators.