Everything posted by Dieselfuture

-

BD Vs. Pacbrake Vs. Banks

This is part of the reason I ended up having my Turbo built, I now have Best of Both Worlds, to a point. Still able to use my bolt on exhaust brake and 62/68/12 it's pretty decent size for what I'm doing, so far I'm happy with the set-up.

-

Electrical cleaner. Memory help

Alcohol works pretty good for that

-

Electrical cleaner. Memory help

You can get electrical cleaner just about at any part store

-

Is mild steel okay in fuel tank?

I swear they hire retards for counter help, I've talked to few mechanics actually knew one pretty good from working out together back in late 90s and back then he was telling me diesel is where it's at, but I never listened. Talk with him every now and then and he's always arguing with people at office. So they do have some decent guys working there but more then likely you'll get stuck dealing with someone at office and they are plainly book smart. I actually went to few seminars for work and Cummins guys were there is asked them a simple question about their fleet guard antifreeze and never got a straight answer, we'll you need to do samples and see where you're at and bla bla bla, and question was is it good enough for my truck as it is as advertised or does it need additive right of the bat. Apparently as soon as you put in the engine you need to take a sample and take to the lab and tell them where you are using it and they will tell you what else to add to it, but jug says compatible with any engine as is, least to say they are zombies.

-

2000 to 2002 Steering upgrade

Lol I actually have for short time, but when I really felt some waight is when I built my own 20" rims out of military split rims, took 2 to make one and some custom cut centers. Just the rim weighed about 90lb and tire was about 380lb I put them together and on my truck all by myself, it was fun least to say. I manhandled all of it, but I was young then. When I went to get my tires guy couldn't belive that I loaded them all buy my self, he had bad back and said I was crazy, I know now why as I got a bad back now lol, I'll never learn probably die before I do.

-

BD Vs. Pacbrake Vs. Banks

I heard where people put hx40 or something like that on with a 4 inch downpipe right from the turbo, what I mean is it doesn't bush out it's true 4 inch

-

BD Vs. Pacbrake Vs. Banks

does your exhaust brake flange come out as a 4-inch? If that's the case I'll definitely go with your setup, mine is only 3" then bushes out to down down pipe that is 4 inch and then it turns to 5 inch

-

Is mild steel okay in fuel tank?

- BD Vs. Pacbrake Vs. Banks

I got a BD the one that replaces a back flange on the turbo, I thought installation was fairly simple just took some time to install. Works pretty good especially in higher RPM. just need to consider if you're ever going to upsize your turbo from 3 to 4 inch, then you probably should look at in line installation vs the ones that bolt to turbo.- Not starting after warm

@Mopar1973Man so it looks like it got to about 10 psi is that too much then and why you created relay mod to not have it come on at all. And that relay you pulled I'm guessing that is to kill power to vp so you could crank longer without starting. I know a lot of people don't have a delay relay at all like me for a long time, are we just waiting for trouble or we're just going to wear out relay sooner. And what I've mentioned before about cold weather starting, if we're at 10 psi cranking pressure seeing how your AD is behaving, it may contribute to harder starts. And if there was 0 psi on cold start it may fire up sooner because it wouldn't be advancing with pressure idk- Not starting after warm

Would it be safe to say because my truck starts so fast why I and many others have no issues with too much pressure at start. And maybe why when it's cold out and it takes longer cranking times to fire engine up pressure is rising too high and on top of being cold it's also fighting higher pressure because of longer cranking where lift pump has time to build pressure. Another thing I heard that when cranking ecm cuts voltage to reduce speed of pump and pressure but with a relay if there is still enough voltage to energize coil pump will run at full psi, kinda confused here. I'm sure that's why the second delay relay is needed to avoid that, but... when is it necessary when cranking times get longer because of air in fuel cold weather bla bla bla.- 2000 to 2002 Steering upgrade

Maybe he meant to say that when people put bigger tires on, a lot of times they put aftermarket rims on too, which are heavier so total weight will contribute to even faster degradation of power steering fluid and wear and tear on the gearbox and other parts. I'm just making things up as I go trying to read between the lines.- Who here is running a Fass Titanium?

Wow nice and clean ^^^^ I would definitely not be scared of setting my sandwich inside that fender working on that fass- Not starting after warm

Industrial Injection would be my choice- Lift Pump Question

I'm thinking you're thinking correctly, but I've only started to drink coffee. funny thing is this is something I would ask your advice on.- Is mild steel okay in fuel tank?

No kidding, especially if you're a good parent and care. It's a full time job no doubt about it. Most of us can relate. Probably not very common but if a good sized stick bounced up off the toad and got in between fuel line and tank, who knows what would happen. I'm not against sumps but they have their own place.- Testing Injector Pop Pressure in the real world

Oh learned something new again I'm going home now, waight I'm already there .... not sure why commented.....losing my marbles I think, am I glad weekend is around a corner it will be grilling time, been way too long since I did that- Who here is running a Fass Titanium?

- Is mild steel okay in fuel tank?

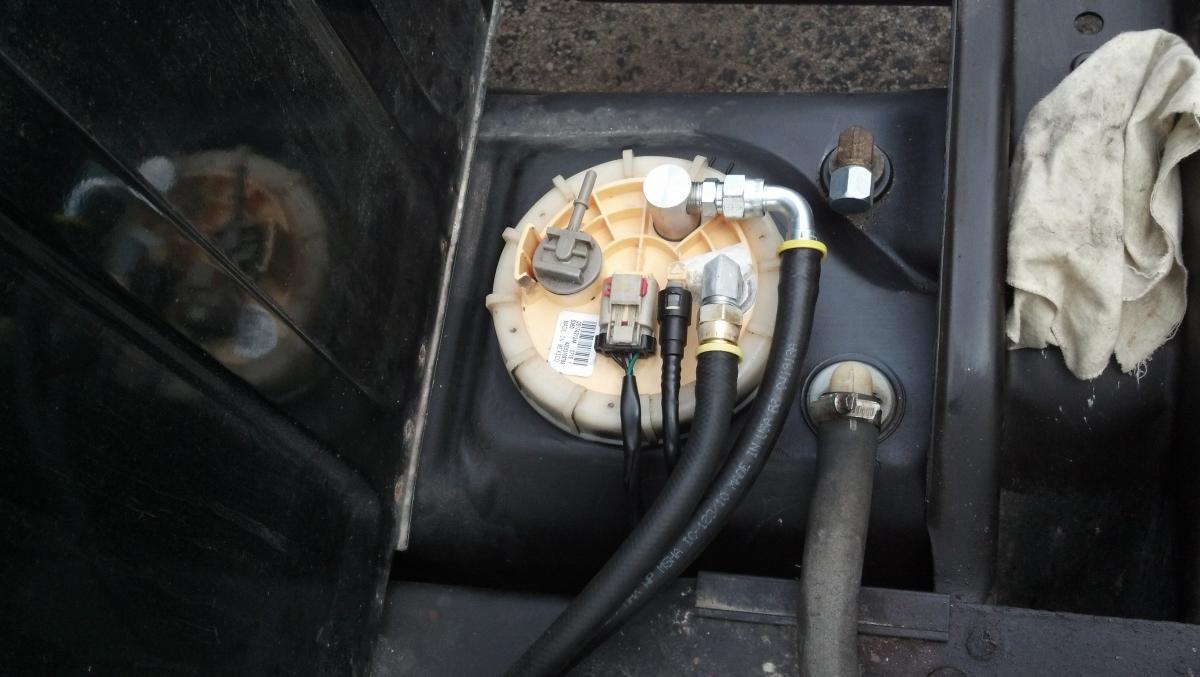

Not sure if that pump has a return from looking at picture but for that amount I think fass 150 is a better design, if a seal wears out on BD pump fuel will go right in motor unless it's double sealed, where fass is sideways with a wheep hole so when there is a leak fuel supposed to leak outside of motor at least that's how air dog is and the look look very similar only fass if 1.5 times bigger and flows more. Sorry got sidetracked, I have 2 returns, one from fass to basket in 1/2" so whatever fuel doesn't get pushed through vp returned, one from vp and injectors T together at back of the head and return to basket through original passage. Fass Supply and return is from Vulcan drawstraw straw 5 kit. I had to make up my own return as back in the day Vulcan only sold the supply and me and him had a long chat and I'm glad he listened and now kit comes with both. In and out both 1/2". I got close to empty where I had 5 gallons left which is close enough for me, I could of socket it dry on level road I'm sure, but I usually never get below 1/4 just my rule, not only for emergency but to keep things happy. If your pump doesn't have return I would not use basket, I would just use old school draw straw like @Mopar1973Man has, otherwise you'll suck it dry. if there is no return this pump shouldn't be used at all unless it's somehow regulated for set pressure, because if it's constant it will rise way to high for vp. Edit, forgot to mention ether sump or basket will be useless on steep grades and before going off road I'd recommend having a full tank. I also think sump is more suitable for drag strip and should be mounted in the back, if it's in middle like most do then going up or down steep grades with empty tank would not be so good with ether set up.- Engine rebuild

I personally would not take anything to to Cummins, especially the ones around where I am at. It seems that they hired all the retards out there. The price is ridiculously high, if you can put the motor together yourself I would find a good machine shop and spend extra money on better parts. @TFaoro might be able to point you in the right direction, as he just went through it.- Who here is running a Fass Titanium?

Short bed but yes first front bolt- Is mild steel okay in fuel tank?

I drilled 3 3/8 holes and popped the fine screen off the bottom but left coarse one alone along with red check valve.- The exhaust brake on my 2002 Dodge Ram 2500 stopped working

If it uses vacuum I'd start there, or a lose wire maybe- another dusted cummins

I fell for this long time ago When I bought my truck I had k&n on it but luckily not long after i joined this site and got straightened out.- U Joints

Another thing Id like to mention on good vs not so good quality of u joints, good ones like Spicer will have smaller in diameter needle bearings but more of them it helps to spread load more evenly and because they don't roll over very far smaller bearing tent to go further and cover more area where cheaper ones have larger bearings and don't roll a full revolution and they make indentations in u joint itself. I'm not sure if you're following me but I tried. Basically if u joints don't travel at all or very little they wear out faster. - BD Vs. Pacbrake Vs. Banks