Everything posted by Dieselfuture

-

Anyone do any Metal Detecting?

Aren't they all similar, diferent tones for different metals, then you can turn up gain for depth etc. I think just playing with it some, you'll figure it out. Put some random stuff on the floor and see how it acts, then raise it up and and see if signal fades at what distance.

-

Turbo's on newer cars

Shouldn't this be something changed at certain intervals to prevent from expensive bills. Or simply no one knows about it till it's too late ? Are you still keeping the truck, I thought about getting a Highlander for the wife, expensive though.

-

Lower end Knock?

Was the truck warmed up and did you just pull up without shutting it off or was it first start in the morning. Probably normal either way Cummins is clunky

-

Blue-Top vs Redhead steering gear

In the other thread Chevy box, I may try that route if it's built better, with bigger bearings etc.

-

Spitting and sputtering

It's almost like a lose wire, I believe there is a relay in PDC for the pump, you can check that.

-

Headlights not fitting

-

Morimoto HID INSTALL

I mounted some of it behind driver side battery tray and some on the driver side front clip. The one behind battery I used ss self tapers have to have the light out to do it. In case you have to aim lights I attached a picture of where screwdriver goes, not everyone catches that part.

-

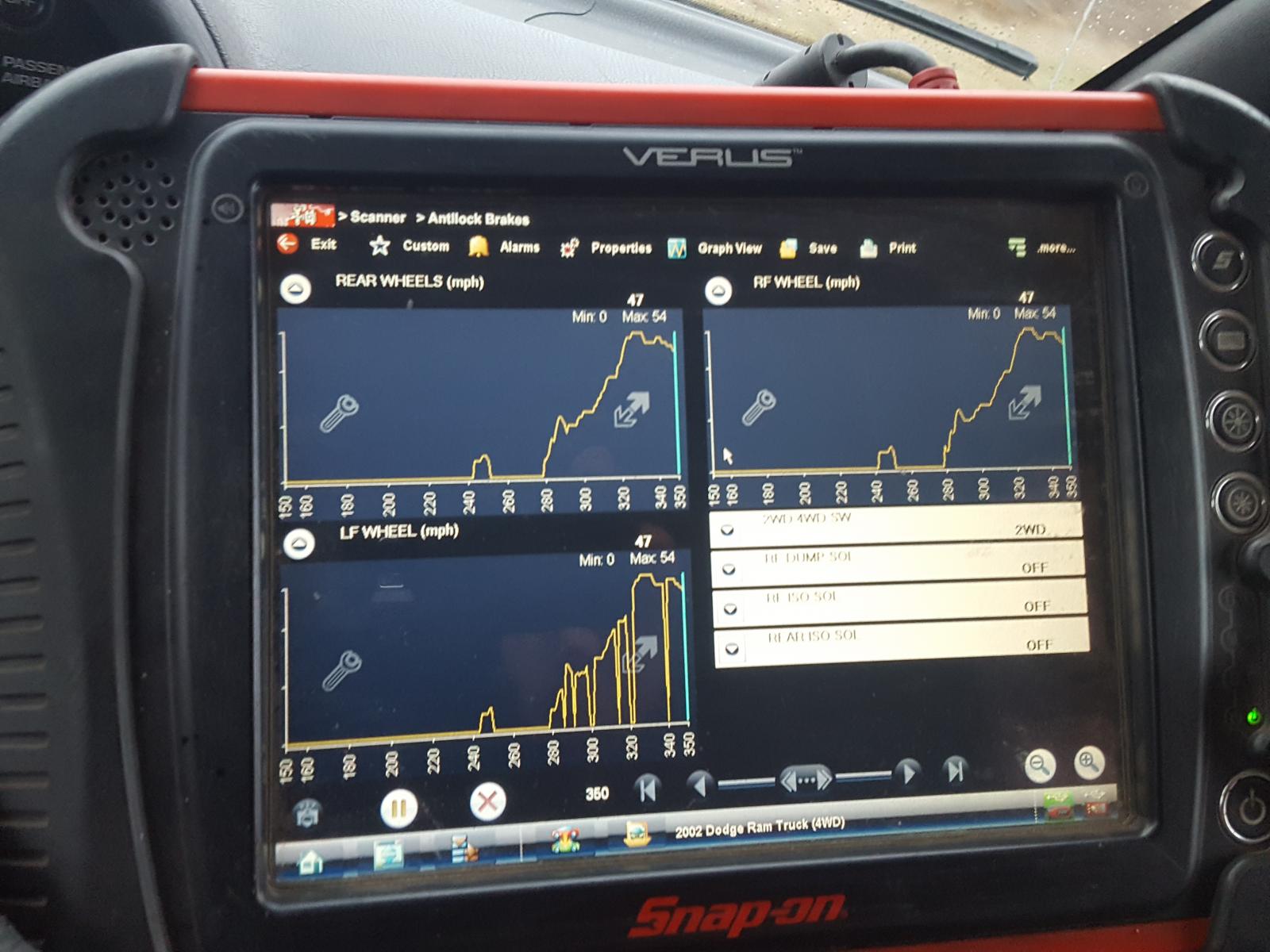

ABS/ Brake light on

I know you mentioned it it more than once now and thank you for reminding me of that, I just feel like it's front hub related. I never had an issue until I decided to grease my original hubs, shortly after I did few weeks maybe, light came on and off. Seems that in the morning it's off until late hubs getup to temperature and then light comes on, if I let it sit for a while it goes off on start up. In the winter it never comes on as I feel grease in the hub never gets runny. Maybe I'll keep driving it and see what happens. I suppose I could swap left to right and see if live data follows, if it does it know it's a hub if not then probably abs computer or wireing. But it's a lot of work to swap it just to see what would happen. That's why I thought maybe file a warranty with rockauto. Just find it hard to believe I had light on before, then changed hubs light went away and stayed away for few weeks then back to how it was with old hubs. What sucks is I never used live data tool to see which hub was doing it and now I'm playing guessing game. Sorry for long reply.

-

New Front Bumper for the TOW-PIG

Nice, good quality

-

ABS/ Brake light on

Weird thing is my original bearings we're acting up, so I bought two new sensors replace them still acting up, now I got two new Timken bearing hubs on the front, still acting up. Thinking about warranting one of bearings back to RockAuto and if it'll still act up then I'll be looking at ABS computer.

-

01 cummins not getting fuel to injectors 1 and 3

Are you getting good flow or just a dribble.

-

01 cummins not getting fuel to injectors 1 and 3

Sometimes it takes awhile to get fuel out of all the lines, as long as you getting fuel out of three close them down and it should fire it up, if starter and batteries are good like mentioned. The other ones will bleed them self once it's running.

-

2000 Honda Accord using oil

I think so. It could be because I separated the base and the sensor on the EGR valve, left the valve plugged in so if commanded to move it could still move freely and filled the hole in the base with J-B Weld and bolted it back on.

-

2000 Honda Accord using oil

What's weird is, I blocked it off on my 88 GT Mustang I had about 15 years ago and it never did set code or light. I think that was about the only vehicle I blocked it off on.

-

Smarty s03 today :)

26* crusing , I'll have to try that. I noticed you're on level 7 (wiretap) mpg won't be accurat, it's not accounted for it. Load will be low like yours at 13 because of added fuel that's not accounted for and MPG would seem high.

-

ABS/ Brake light on

If you have access to live data tool, you can see if one of the sensors is dropping out. In my case front passenger side is acting up.

-

Headlights not fitting

Is this the side that fits good

-

2000 Honda Accord using oil

@IBMobile I cleaned the EGR valve it was all carboned up, it seems to cure stalling issue. Next time it does it I'll probably just block it off and leave sensor plugged in.

-

Top hat valve seal and valve train

I used Manton pushrods conical springs, fit fine. So far no issues.

-

Quad tune 7x10 DD and race

That's pretty good, I'm somewhere there too. Maybe just a tad lower. I mean going from 650 to 550 or 750 crusing doesn't take much of a change really. 1200 is what is considered safe by Cummins continuously. On a race tune if you hit 1400-1500 for few seconds, nothing is going to happen, if you got supporting mods. I've hit 1500 before. My wastegate is unhooked, so it's always shut, I just try to build the tune so it doesn't get over 1200 for normal driving, but race tune .... Yeah it'll get hot a bit. I usually just stay on level 3 all canbus and it's pretty good power for me, I'll hit over 40psi if I floor it. Then with wire tap it'll hit 50 but kinda getting out of control and my turbo is only good for 40 safe psi anyhow.

-

Stock EGT temps

Maybe check it with lazer temp gun at idle to compare

-

Exterior Article - Headlight Projector Upgrade to FX-R projectors

Sexy, I had fun time doing my d2s, even made my own socket for that nut that holds assembly in the housing. Use the piece of pipe and a dremel tool, didn't wanna use channel locks.

-

Quad tune 7x10 DD and race

I've been curious to see what you can reach with your current setup, if 27 is possible with 7x10. I feel like it would be in perfect driving conditions.

-

2000 Honda Accord using oil

Exactly my thoughts, I chanel it every 10k but by the time I do I add like 8qts lol so it's fresh. I get a wix filter that's slightly bigger for longer intervals

-

Quad tune 7x10 DD and race

I still know the guy that bought it from me, he takes it out once in awhile. I can probably buy it back butsadly have no place or time for it now.