Everything posted by 01cummins4ever

-

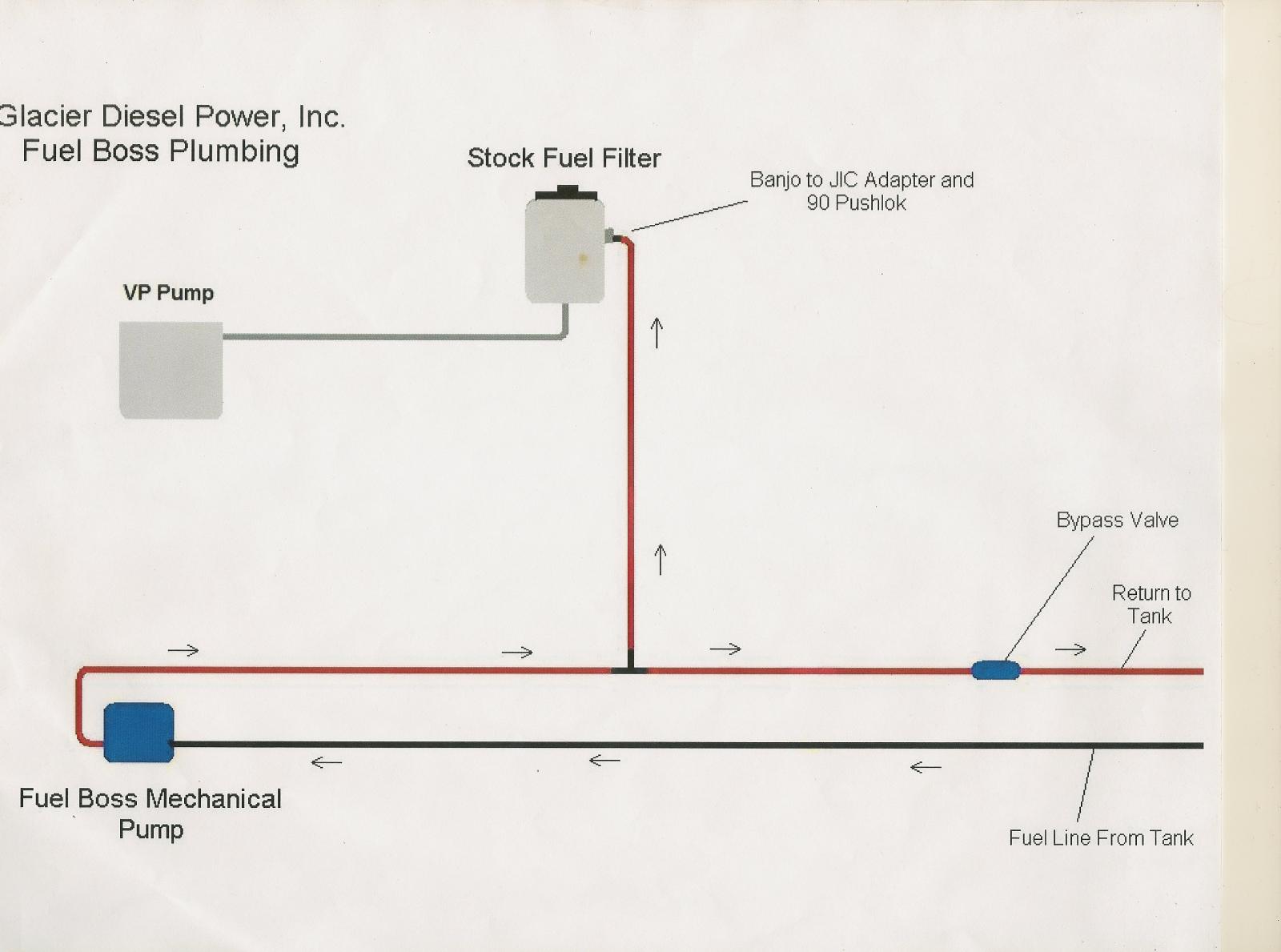

installing a fuel boss

I hope to get this little project tackled this weekend, Since I dont have the factory fuel pump no more, I dont see how I could have a priming pump without adding another straw in the tank to feed the fuel boss. ( or am I missing something) since the set up I have in tank now is the dedicated 1/2" line for the existing raptor. Anyway when I ordered pump and explained it to Richard he suggested it would be easier just to delete the raptor altogether, and not create a plumbing nightmare, If I still had the block mounted pump I would probably just keep it and go with the original lay out for that set up, but since I dont I will just use this simple diagram I dont see how you could prime it with a drill either, but I guess I will figure it out.

-

installing a fuel boss

I ve always told myself if the raptor ever gives up I'm going with a mechanical pump, and so the other day it started giving me fits and loosing pressure, I tried to adjust pressure up but the electric motor just barley running and sound sick so I just gave up on it, and ordered a fuel boss from GDP. My plan is to keep the plumbing as simple as possible, by eliminating a back up electric pump altogether, just dont see a need for it, and if I ever have to prime I will just use the cordless drill method like on filter changes or something. (also going to stick with the factory block mounted fuel filter for heating purpose) So I plan on tapping in on the 1/2" line from tank right where the raptor was mounted on frame and install a 1/2 npt bulkhead with a shut off valve on inlet side and I have a 1/2 " threaded fuel strainer on the other side then reduced to a 3/8 jic push lock and continue the route with the directions provided, thus excluding the hobs switch and bypass valve since no priming pump will be their anymore, also I plan on installing a tee on the return to tank so it spits going into the fuel module and filler neck and hopefully reduce some of the foaming effect and also keep up with the demand in the module from the suction of the fuel boss, So any input from you guys running the fuel boss, or any input in general if this is a good idea or not

-

Morimoto HIDs Headlights in a 2nd Generation Dodge

I can't say for the led, but I've used the yellow halogen, they defiantly cut down on the reflectivity of snow and fog, they were good for short range, not really an all around driving light.

-

Used tractor sanctuary house.

Not a lot of back hoe use, but I do side work and when the job calls for it, I like having the convieneance of everything on the tractor in one package, vs. the inconvieneance of renting. About 400 a day for a decent size mini x after rental fee, taxes and other miscellaneous fees, not including time and fuel to go get the machine which really puts a dent in the profit. I have rented equipment when the kubota 2150 is not up to the task, and have spent thousands of dollars on rentals over the years. Spending the extra 4 or 5 thousand on the hoe attachment will be worth it for me, I am looking at the 47 to 49 horse range, about the largest you can get and still be considered a compact tractor and easy to transport with the dodge and my trailer. The tractor hoes are slower than the tracked machines but it's just a trade off for convienance and I do like the sub frame attachments much better than the old 3 point like my 2150 has. The possibilities are great when it comes to attachments for these tractors

-

Used tractor sanctuary house.

A heated cab, I am so jealous , I was hoping this was the year I trade up to a kubota L49 TLB or John Deere 110 TLB but to much happening right now. so it looks to be another winter on the oid 2150. maybe well get lucky and wont snow much, lol.

-

Harmonic Sound

Have you tried disconnecting the fan belt and then start it to try and isolate the noise ? I would be curious to hear the noise, becouse I had a similar issue a couple days ago in semi truck, a harmonic type sound developed all a sudden, but it ended up being fatal for the turbo.

-

Advice before purchase

I tow with a basically stock 01 shortbed Dana 70, I gross just under 20k with all hooked up About 9500 lb on camper fully loaded, around 7500 on truck and and 2500 on boat. I have pretty much the bare minimum for towing but handles it ok. Like stated before the electric brake controller is a must, I wouldn't leave home with out it. I'm sure the trailer manufactures have the electric brakes as standard equipment, just make sure your truck has the in cab controller. The add on's like Exaust brake and engine performance are great when you can and afford to get them. Like myself they are in the future plans but for now I have no hesitation hooking up and traveling a 1000 miles or so, just have to be cautious and always expect the unexpected (mostly other drivers). Also stay away from the leveling kits if you can they just throw the geometry of the suspension off when all hooked up.

-

If I am going to do tie rod ends and steering components

@Dieselfuture I admire your ingenuity, and thanks for sharing your work, although just wondering why a person would need an adjustable track bar on a stock height truck? Have you ever had to adjust it, and what would determine the need for adjustment, would it be just taking up slack in the ball stud? Or re center the axle for some reason When I did my Luke's links, I did all the joints while I was at it, that was just a no brainer, that was in 2011 and now the track bar joint seems to have a little play so adding a shim with the L.L kit is supposed to fix that, but we'll see I guess

-

If I am going to do tie rod ends and steering components

I installed these years ago and they have been holding up well, I used my original track bar 1994-2002 2nd Generation Track Bar, Tie Rod Ends Luke's Link.url

-

Sure hurts to be dumb

I have stayed their before, it is right next door to the school of hard knocks..

-

Skid steers

You should be able to call any bobcat dealer or even go on line to bobcat web site and give them your model # and vin # and they should be able to set you up with a genuine and correct service manual. it may cost more than an online download but the quality will be worth it. The cost of the manual will probably be the cost of about 1 or 2 hours shop rate and the knowledge will be priceless. A lot of them come in a hard copy or a cd style, I would prefer a hard copy if working on something that way the information is right in front of you and you don't have to keep going back and forth to a computer, but that's just a personal preferance. It looks like you got yourself a good deal thier, hope it all works out for ya

-

Skid steers

The download versions are usually penny's on the dollar compared to the acuual hard copies, mostly they are just reprints. so sometimes the clarity is not that great. I would check out all the reviews on one before I ordered it.

-

Skid steers

Go on line and find a downloadable service manual, it will be your best friend on repairs like that. You can probably find a parts and operators manual too. with that amount of hours Im sure it has a lot of life left in, although it may have a few issues, but hopefully nothing you can't take care of. as got the hand/foot controls that's common on just about all of them that I've been around, you will get used to them.

-

Morning Pic For Today...........Post A Pic around your place.....

Finally got that link to open, nice job @JAG1 , Does that wheel drive something? None the less it's a cool water feature

-

Fiberglass Topper cracks

Nice job what your doing, I too believe you will appreciate this much more with the labor of love you got invested, sometimes just adding that personal touch makes it much better than some factory knock off, and the time you get to spend with family doing it makes it that much better. on on a side note.. I've been wanting to build a custom head ache rack and diamond plate tool boxes to accommodate my fifth wheel set up. Got it planned out in my head but time is just not on my side

-

Towing a 3500 after major breakdown.

Good towing insurance on your policy helps tremendously. My truck only left me stranded one time in the last 16 years I've owned it. The VP went out while pulling the 5ver back home from a trip. I was about 250 miles from home when I heard a bang under the hood, truck lost power and check engine light came on. I got to side of road and that was the end for my original vp. It had about 200 k on it at the time. I knew nobody in the area, so I called roadside assistance on my insurance policy and told them what I had and all they could find was a class 8 tripple axle semi wrecker from a town 30 miles away. That bill was about 450 bucks for a 30 mile tow, but all I had to do was sign a paper and they took care of the bill. and they towed it to a local dodge dealer, but that's another story, things got worse from thier. If I had known what I know now I would have just replaced the Vp and redone the fuel system where I was.

-

Great Songs

Neil young "unknown legend" Belllamy brothers " old hippie" thanks @Me78569 my computer hates me

-

Great Songs

don't know what problems is, I just tried to click and drag link ?

-

Great Songs

https--m.youtube.com-watchv=40YzTpxrdZQ.url

-

Great Songs

and another 80's flashback https--m.youtube.com-watchv=40YzTpxrdZQ neil young.url and kind of the way I feel trying to connect with my kids, not that I just turned 35, or promote smoking pot but the meaning is the same https--m.youtube.com-watchv=MzdvQOXxRD4 old hippie.url

-

Headlight options

Clear, with a very light tint on mine. I have been using the sport headlight conversion, the ones sold by DAP, for about 9 months and I like them, with my original headlights faded out to the point of no return and experimenting with cheap eBay junk, these seam to be of decent quality, have had no leak issues and they throw a clean and consistent light. For the wiring side of it, the light relay harness had some issues, mostly from not being wired right for my application, it was pretty much *** backwards and had to re-wire from scratch. The only other thing is that on the high beams they don't quite reach out far enough according to me, they seam bright out to about 500 ft. and quickly fade after that. maybe about 700 ft. of total illumination. But maybe that's about as good as your going to get with halogen bulbs. I will probably do a little more experimenting with it in the future but it has been a major improvement from what I had before.

-

leaky brake booster

@Haggar thanks for posting that. I went ahead and resealed mine without pulling the rod but so far so good, but if I have to go in it again this will help

-

Going to look at this tonight

Any fish ?

-

leaky brake booster

Yes. I put it back together last night without doing the rod seals, even though I got a welder I didn't want to cut the rod in half, and weld it back and have it look Ike a patch Job. I just replaced the piston seal and the figure 8 seal that mates the two halves together, so far no leaks. If I was to cut the rod I probably would do a threaded sleeve, and cut some threads on both ends of cut rod, and that would maybe allow you to reuse your original brake light switch by being able to adjust the brake rod out a little, might be worth a shot if you have to replace the rod seals.

-

leaky brake booster

So I used the above article for resealing my hydroboost, but it doesn't address replacement of the input rod seals. Reading the instructions that come with the pirate jack kit, it appears that the brake rod on our trucks use the staked design and rod has to be cut or some other way to remove, (I don't want to go thier) or am I looking at this wrong. Anybody got any input on this, I kind of would like my truck up and running this afternoon . I did get the piston seal in, which was the major culprit of my leak, but I do have a sign of small seepage on firewall inside of cab.