Everything posted by Mopar1973Man

-

Ultra Gauge

Sad to say I've got a true first line SGII. Software version 1.00 there has been lots of updates. Free updates only if I can provide a receipt, but mine is long gone.

-

dead pedal and hot weather

AirDog 150. Fuel pressure is 17-18 at idle and about 16 PSI at WOT.

-

PCM Issues

In a pinch you could do a old school regulator but be warned it will not charge the same as the temperature controlled PCM. http://articles.mopar1973man.com/general-cummins/34-engine-system/134-voltage-regulator-mod

-

PCM Issues

Field lead have to be tested unhooked. Because the alternator field is nothing more than a short. So now the blue wire should be 12V (POSITIVE) and the green wire should be a variable GROUND.

-

Duramax - Fuel filter change

We had a gent have his Duramax towed in to the shop after filling it with gasoline. Yea he filled to full with gasoline in a diesel truck. Managed to drive just about half way home and it died. So went through the process of draining the fuel tank, disposing of the mixed fuel, and putting 10 gallons of fuel back in. Now Lindy ask me to change the filter. OMG! I'm looking at this going it going to be fun. Drain the filter and spun it off. Now how in the heck do you get it out. I finally figured if you drop it into the A arm on the passenger side then you can lay on the floor and lift it up and squeeze it back through the fender skirt. So now reverse process of installing. No fun at all. Then hearing about the price of a Duramax filter I about choked.

-

Flippin' HOT!

Most every knows I live up here in Idaho and most would think this far up north the summer would be rather mild. Well today when I left the shop the temp in the 1996 Dodge showed 108*F. Ugh... So what's every else seeing for temps?

-

Ultra Gauge

Not that I know of. As far as I know its PSIa (atmosphere). Like I said it only a weird issue with the 24V Cummins.

-

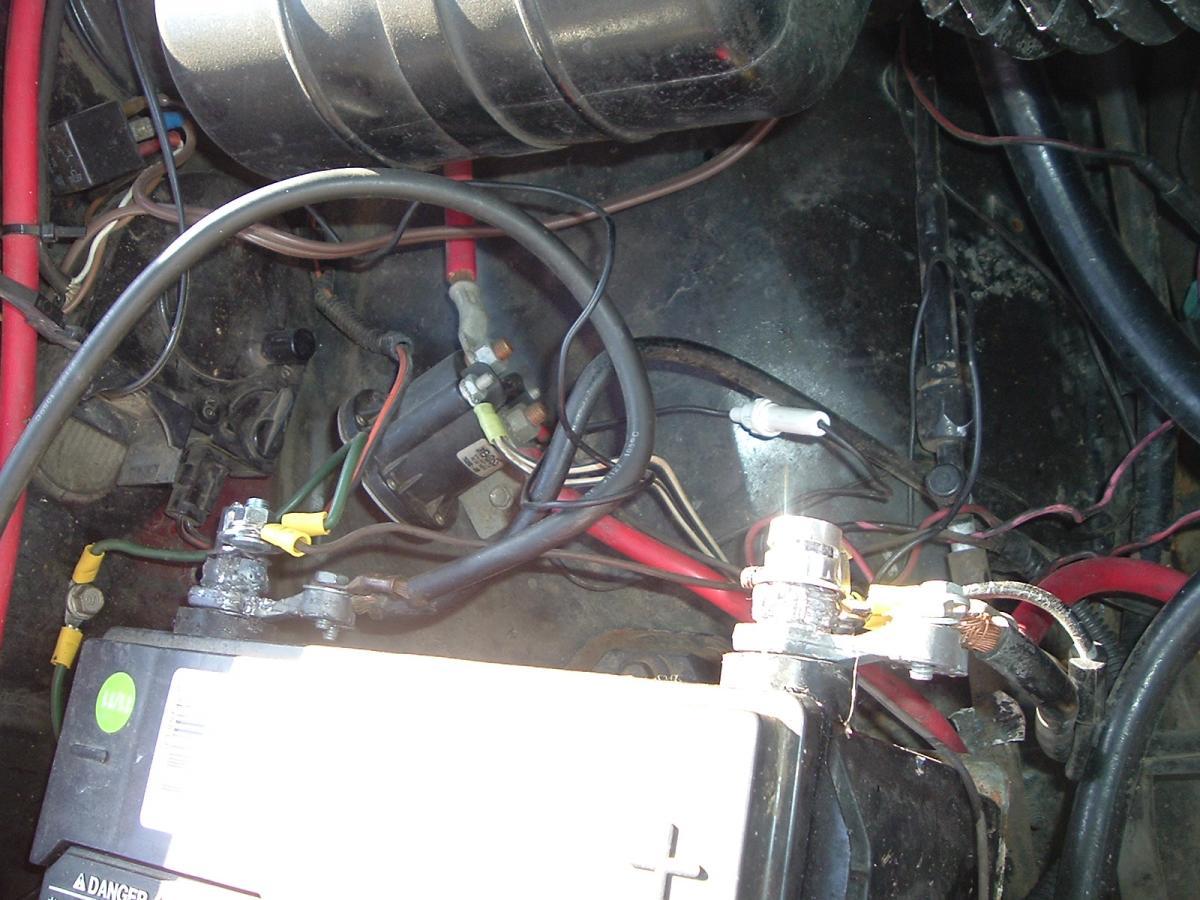

How not to wire a vehicle

I got a vehicle in the shop today that was a wiring nightmare. Easy fix but talk about "How not to wire a truck".

-

Camper Trip with Bud's Duramax Following.....

There is all kind of factor that could change it. But yeah I would have to say that's awfully weird to hit the same price.

-

Ultra Gauge

Yes and no. From 0 to about 20 PSI its correct then slow there is a offset as you run outside the designed range of the sensor. As for SGII the newer software on the SGII does have boost gauge and do show correctly but again also has the same loss of accuracy as the Edge Juice. Outside the designed realm of the sensor.

-

What would cause fuel gauge to read higher?

I know the member is here on the site but who is the question.

-

dead pedal and hot weather

You can try replacing the lift pump and see if you can gain some time from the VP44 but only the Good Lord knows if thee VP44 is damaged or not.

-

PCM Issues

Check your fuses. Check your error codes there might be a clue there. Check your negative terminals. All grounds for the ECM, PCM and VP44 are in the battery cable there is no external body grounds.

-

dead pedal and hot weather

Ummm... The PSG on top of the VP44 is overheating. Your WOT pressure needs to be above 14 PSI as a minimum. Idle doesn't count because the VP44 isn't under stress but WOT it being highly stressed electronics are creating more heat and the return flow to the tank is close at pressures below 14 PSI. So now you lost all cooling of the PSG.

-

What would cause fuel gauge to read higher?

Really common for fuel gauge to start showing higher level on the gauge when rheostat starts failing. Mine failed and was empty at 3/8 of a tank.

-

A stark realization...

With all the changes it still doesn't do anything for long term storage of gasoline. As long as its stored in a vented tank then the fuel is going to go stale in a period of time. But air-tight container like my 55 gallon drum it will hold for a very very long time. Yes my bungs are o-ringed even and hold pressure or vacuum quite well.

-

Ultra Gauge

Not sure why. But the SGII works just fine one all other vehicles. Just the 98.5 to 02 Dodge Cummins is skewed in value. I've not figured out why yet.

-

dead pedal and hot weather

What your fuel pressure at WOT at highway speed?

-

OBD code P0222

Here is the diagnostic article. http://articles.mopar1973man.com/2nd-generation-24v-dodge-cummins/59-obdii-error-codes/163-p0222-idle-validation-both-low DTC P0222: IDLE VALIDATION SIGNALS BOTH LOW Monitor & Set Conditions Idle validation signals are monitored when ignition is on and engine is running. DTC P0222 may be stored if Engine Control Module (ECM) senses no voltage signal or the same voltage from Idle Validation Switch (IVS) No. 1 and IVS No. 2. DTC P0223 may be stored if ECM senses the same voltage from IVS No. 1 and IVS No. 2. Possible Causes Accelerator Pedal Position Switch (APPS) Idle Validation Switch (IVS) No. 2 Harness Short To Ground APPS IVS No. 2 Shorted To APPS Return Circuit APPS IVS No. 2 Shorted To APPS Sensor Ground IVS No. 2 Open Between APPS And ECM Harness Connectors APPS IVS No. 1 Shorted To APPS Sensor Ground APPS IVS No. 1 Shorted To APPS Return Circuit APPS IVS No. 1 Harness Short To Ground IVS No. 1 Open Between APPS And ECM Harness Connectors IVS No. 1 Circuit Open ECM Testing 1. Turn ignition off. Disconnect APPS harness connector. APPS is located on bracket, just above fuel injection pump. Check for poor connection/terminal contact at APPS harness connector. Repair as necessary. Start engine and allow engine to idle. Using DVOM, measure voltage between ground and terminal No. 6 (Brown/Orange wire) on APPS connector. This is the IVS No. 1 circuit. If voltage is greater than 4.5 volts, go to next step. If voltage is 5.5 volts or less, go to step 8 . 2. With engine idling, using DVOM, measure voltage between ground and terminal No. 2 (Light Green/Dark Blue wire) on APPS harness connector. This is the IVS No. 2 circuit. If voltage is 4.5 volts or less, go to next step. If voltage is greater than 4.5 volts, test is complete. 3. Turn ignition off. Check for continuity between ground and terminal No. 2 (Light Green/Dark Blue wire) on APPS harness connector. If continuity exists, go to next step. If continuity does not exist, go to step 7 . 4. Ensure ignition is off and APPS harness connector is still disconnected. Disconnect ECM harness connector. ECM is located on driver's side of engine, just in front of fuel transfer pump and contains a 50-pin connector. Check for continuity between ground and terminal No. 2 (Light Green/Dark Blue wire) on APPS harness connector. If continuity exists, repair short to ground in Light Green/Dark Blue wire between APPS and ECM. If continuity does not exist, go to next step. 5. Ensure ignition is off. Ensure APPS harness connector and ECM harness connector are still disconnected. Check for continuity between terminal No. 2 (Light Green/Dark Blue wire) and terminal No. 4 (Black/Yellow wire) on APPS harness connector. If continuity exists, repair short between Light Green/Dark Blue wire and Black/Yellow wire. If continuity does not exist, go to next step. 6. Ensure APPS harness connector and ECM harness connector are still disconnected. Check for continuity between terminal No. 2 (Light Green/Dark Blue wire) and terminal No. 1 (Black/Light Blue wire) on APPS harness connector. If continuity exists, repair short between Light Green/Dark Blue wire and Black/Light Blue wire. If continuity does not exist, replace and program the ECM. See appropriate REMOVAL, OVERHAUL & INSTALLATION article. 7. Ensure ignition is off and APPS harness connector is still disconnected. Disconnect ECM harness connector. ECM is located on driver's side of engine, just in front of fuel transfer pump and contains a 50-pin connector. Check continuity of Light Green/Dark Blue wire between terminal No. 2 on APPS harness connector and terminal No. 16 on ECM harness connector. If continuity exists, test is complete. If continuity does not exist, repair open in Light Green/Dark Blue wire between APPS and ECM. 8. Turn ignition off. Ensure APPS harness connector is still disconnected. Check for continuity between ground and terminal No. 6 (Brown/Orange wire) on APPS harness connector. If continuity exists, go to next step. If continuity does not exist, go to step 12 . 9. Ensure ignition is off and APPS harness connector is still disconnected. Disconnect ECM harness connector. ECM is located on driver's side of engine, just in front of fuel transfer pump and contains a 50- pin connector. Check for poor connection/terminal contact at ECM harness connector. Check for continuity between terminal No. 6 (Brown/Orange wire) and terminal No. 1 (Black/Light Blue wire) on APPS harness connector. If continuity exists, repair short between Brown/Orange wire and Black/Light Blue wire. If continuity does not exist, go to next step. 10. Ensure APPS harness connector and ECM harness connector are still disconnected. Check for continuity between terminal No. 6 (Brown/Orange wire) and terminal No. 4 (Black/Yellow wire) on APPS harness connector. If continuity exists, repair short between Brown/Orange wire and Black/Yellow wire. If continuity does not exist, go to next step. 11. Ensure APPS harness connector and ECM harness connector are still disconnected. Check for continuity between ground and terminal No. 6 (Brown/Orange wire) on APPS harness connector. If continuity exists, repair short to ground in Brown/Orange wire. If continuity does not exist, test is complete. 12. Ensure ignition is off and APPS harness connector is still disconnected. Disconnect ECM harness connector. ECM is located on driver's side of engine, just in front of fuel transfer pump and contains a 50-pin connector. Check for poor connection/terminal contact at ECM harness connector. Repair as necessary. Check Brown/Orange wire for continuity between terminal No. 6 on APPS harness connector and terminal No. 1 on ECM harness connector. If continuity exists, test is complete. If continuity does not exist, repair open in Brown/Orange wire between APPS and ECM.

-

Removing Steering Gear box Pitman Arm

Redneck method... I normally pull the steering gear box off the truck. Loosen the pitman arm nut. Then remove the sector adjust cover. Remove the nut from the pitman arm. Then with a 2x4 and small sledge drive the output shaft out of the pitman arm. No special puller required. But hey that's how this Idaho Redneck does things...

-

A stark realization...

Well I've got two 55 gallon drum on the property filled with both gasoline and diesel fuel. Use a barrel pump and pump out the needed amount of fuel for generators, ATV, vehicles, etc. I've found that as long as your drums have sealing lids the fuel will last a very long time. So now back to your RV. Both tanks are vented so if you would to fill the tank and leave the fuel for a very long time then the fuel would most likely go bad. Like here I've got a 6,500w gasoline generator which holds about 3 gallons of fuel. I "try" to make a habit of running the generator once or twice a month. This allows the engine to get exercised and slowly consume a bit of fuel to allow the fuel tank to be freshen often. When I'm done running the generator I turn off the fuel leave the ignition alone. Wait.... Wait... Soon enough the carburetor runs out of fuel and the generator is ready for storage. So in your case I would consider the aux suction more so to hopefully keep from worrying about stale fuel in the generator tank or the storage tank. Like I said if the fuel is stored in a air tight container it will last a very long time but vented tank you have to consume the fuel at some point because the fuel will go bad. So reconsider your storage of your fuel.

-

Battery Tray Bolts for 1999 Cummins 24V

Typically they are just little metal clips in the tray as shown in the PDF above. I usually will put a dab of anti-seize on the bolt threads, then install. But also make it a maintenance thing to dribble engine oil down the bolts so the bolts don't corrode from the battery acid. To this day my bolts are unharmed the clips are still 100% great condition.

-

Ultra Gauge

Nope its not broken the 24V engines have a voltage offset that creates this issue. The early versions have a different voltage span vs the later versions witch now have a different span. So the numbers on scan tools are skewed out. I've got 2 sensors with the same numbers. No error codes. Best I can say is look at the series of different MAP sensors on the 24V. There was like 3 different ones but the 01 and 02 are the same and interchangeable with each other as long as you used a adapter cable. (Pins where different). Just a modified MAP sensor voltage. This is only a 24V issue. Corrected after 03... LOL... Smoke switch. I've played with that and it just buried the SG to 37.3 PSIa and stopped. But now look at my Version of SG vs. the new version of SG (software wise) they do have a valid boost gauge now vs. mine which had this skewed MAP reading.

-

Ultra Gauge

Confirmed on the boost...

-

Going Solar Powered On The Rv

Starter kit. (At least what I picked up) http://www.harborfreight.com/45-watt-solar-panel-kit-68751-8527.html http://www.harborfreight.com/1200-watt-continuous2400-watt-peak-power-inverter-69659-8890.html Mopar Mom wants me to build another soon for the guest house for keeping the refrigerator going and a few extra watts for other things down there. I'm thinking like 2-4 deep cycle batteries, solar kit again, 2kw inverter.