Everything posted by Mopar1973Man

-

2nd Gen. 24V convertion to 12V

I get a good laugh from you Rogan... Thanks...But the simple thing is with any of the Cummins line you can invest some serious money and make it bulletproof (so to speak). But Question you got to ask is how much money are you will to lay down to make it bulletproof?ISX does bring up a good point of the old 12V's and there ability to limp home with next to nothing. But once again it about being aware of your vehicle I don't care if its a 12V, 24V or CR truck each one has its sour points (as pointed out). But in any of the vehicle models it all about being aware of your vehicle and keeping the maintenance up. Like ISX point out you notice a loss of power and performance over time. Well that true with any of the Cummins models (12V, 24V, CR, Etc.) but most people tend to shrug it off to poor fuel, winterized fuel, bad hair day, wifes in a bad mood, etc. Instead of actually looking into the issue.Like on the CR engine I see more people rebuilding engines from failed injectors. Like on the 24V engine I see more VP44 failed from no fuel pressure gauge, crappy fuel, and crappy fuel filters.!2V's well they are nearly bulletproof but there is a lack of user adjustablity with the engine. Like timing a P7100 or a VE pump requires special tools to do it properly. Yes. I know ISX has a fallback plan to get stock timing. 12V's tend to do much better in the MPG department compared to any other series of engine with 6.7L being the worse in MPG's from all the smog equiptment. Now a person like ISX is knowledgable and he's very capable of doing most anything to his truck and keep it going. But from a Common Joe aspect I tend to try and keep it simple and easy.

-

Hard to find leak in my camper

Well your suppose to use caulking tape for it but... Me I've been using clear silicone around all the joints and seams of my RV. It got a fiberglass body and silicone seems to adhere just fine to it. The only trouble with silicone what ever color it tend to hold on to road dust rather well making it stand out more but after washing it the RV it tend to disappear again...

-

Window power

That's a start...

-

Hard to find leak in my camper

I don't know...But I've seen this... http://youtu.be/PeoTlfnkNZQ

-

Info needed Asap please fellas

Yes... The allen screw with lock nut. Don't over adjust it will cause the steering to bind up in the center... Do it a little at a time and test drive.

-

Just my luck

Don't that suck... :duh:I get the same thing by spring time here a yard full of turkeys and deer...

-

Window power

Make sure you windows regulator arms are still lubed up and not jaming up...

-

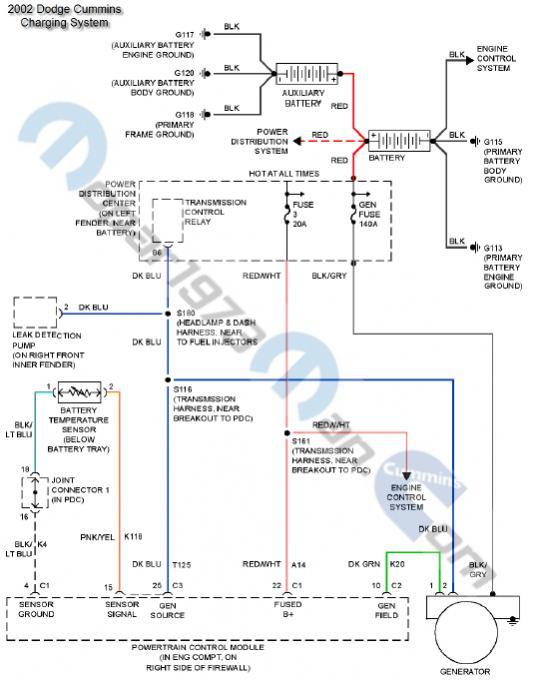

battery voltage peaked

Check the green wire between the alternator and the PCM for shorts to ground. If this wire shorts to ground the alternator will run wild at max voltage...

-

stickshift switches

In my old 1972 Dodge PowerWagon I had a 2 ball and a 8 ball... The truck was blue so now you know why the 2 ball...

-

2nd Gen. 24V convertion to 12V

Ok... Let me let you in a secret... I live in the middle of nowhere Idaho. I travel great distances just for basic things like groceries is a 70 mile round trip. Auto part store is 104 miles round trip. WalMart is worse at 350 miles round trip.There is 3 thing the VP44 need to run a long happy life won't needing to pack around spare any thing...1. Good fuel pressure and volume. You fuel pressure should always be 14-20 PSI with only a 2-3 PSI fall from idle to WOT at highway speed.2. Good fuel filters. You stock filter can is OK if you use a high quality filter. Should try to get below 10 micron. AH64ID is the filter guru of the site.3. Lubricity. Bosch design the pump around <450 HFRR lubrcity and today's fuel is ~520 HFRR so the higher the HFRR number the less lubricity and more wear occurs. My VP44 has performed remarkably well I've got a AirDog 150 with 2 micron filters and 128:1 shot of 2 cycle oil in the fuel. I'm coming up on 150K on the clock for the VP44 and the truck is coming up on 200K miles.Vp44 fuel system are rather good performing don't fail if you understand the weakness of them. Like you mention the wanting the Ppump for it being fully mechanical. Well it got few weak points too like the mechanical lift pump is not efficent at high RPM's it start losing volume. The list go es on too...

-

stickshift switches

Ahhh... Understand... You going to be in direct control of the exhaust brake. (Suggestion) You could hook it up on a keyed power lead then not have to worry about the position of the switch then...

-

stickshift switches

I used a piece of angle aluminum and drill 2 holes and used a U bolt to fasten to the stick then picked out a nice Blue LED rocker. The LED blew out in a few second after hooking up. There is a hell of a surge from the vacuum solenoid which blows out normal bulbs or LEDs...I like the rocker because I can sweep my thumb back and forth to control the jake instead of push/pull.

-

Cracked exhaust manifold 98.5 24v

I don't see any reason for aftermarket exhaust manifold till you making big power or this going to track runner truck where its either WOT or idle...

-

2nd Gen. 24V convertion to 12V

Just for the p-pump and the misc part and high pressure lines it roughly $3,500... http://www.alligatorperformance.com/industrial-injection-p7100-stock-fuel-pump-fits-96985-dodge-cummins-p-5936.html http://www.alligatorperformance.com/industrial-injections-iisss24vppcov-ppump-conversion-98502-dodge-valve-cummins-p-4710.html Personally I would learn how to maintain the VP44 it much cheaper...

-

I need some help diagnosing my heat problem please

Passenger side of the trans hump is the stepper motor for the blend door... Turn the ignition to ON and not start the engine. Then turn the temp knob left to right and watch the shaft.

-

Need Help!! Electrical issue???

The only way to be sure is get a hold of a dealer and have them drop there DRBIII tool on there and run a diagnostic on it. That will hurt for at least a shop hour at the dealer... (~$100)

-

Wasted Wastegate

The turbo on the left sure looks like a HY35 (your old one). But the one on the right sure is a HX35...So this will be a upgrade for you... 9cm2 to 12cm2 exhaust housing!

-

1996 Dodge 1500 - Looking for MPG's

Short clip of heading towards New Meadows yesterday...

-

Mpg...

Last that I've heard like 23-24 MPG... Empty of course...

-

Seafoam? Yes or No

Dang children... Being :moon:and need there ...

-

Seafoam? Yes or No

I tried a can as suggest by one of our vendors during my injector problems. Well I will say it does a wonderful job of masking the actual problem. The misfire came back as soon as the seafoam was consumed. As for cleaning the injectors never happened. As for reomving the injectors and soaking them in straight solvent... Never changed a thing... You literially have to scrub each and every piece of the injector to clean it. I will say it again... "There is no cure in a can!"

-

2nd Edge Ez in the Can

Common problems with Edge EZ is that its mounted under the hood it get hot and cold. Then the case isn't sealed very good and I've several get water inside and corrode the circuit board...Edge Comp is mounted in the cab... No issues here...

-

1996 Dodge 1500 - Looking for MPG's

Well after doing the plenum gaket and fixing some odds and ends so far I'm looking like I can reach 16-17 MPG on the ScanGauge II but with the weather being foul, cold, windy (head wind), etc. I only got 15 as of yesterday which I'm not crying about actually I'm quite please with it after looking back at some of the fuel history and some being as low as 10-11 MPG...

-

How much does your truck weigh?

I said "Cummins ISB Engine" not the Dodge Truck... We all know the body would never hold up to that kind of weight. But the engine would...

-

Seafoam? Yes or No

Don't give me that much credit...