Everything posted by Mopar1973Man

-

MAP sensor error

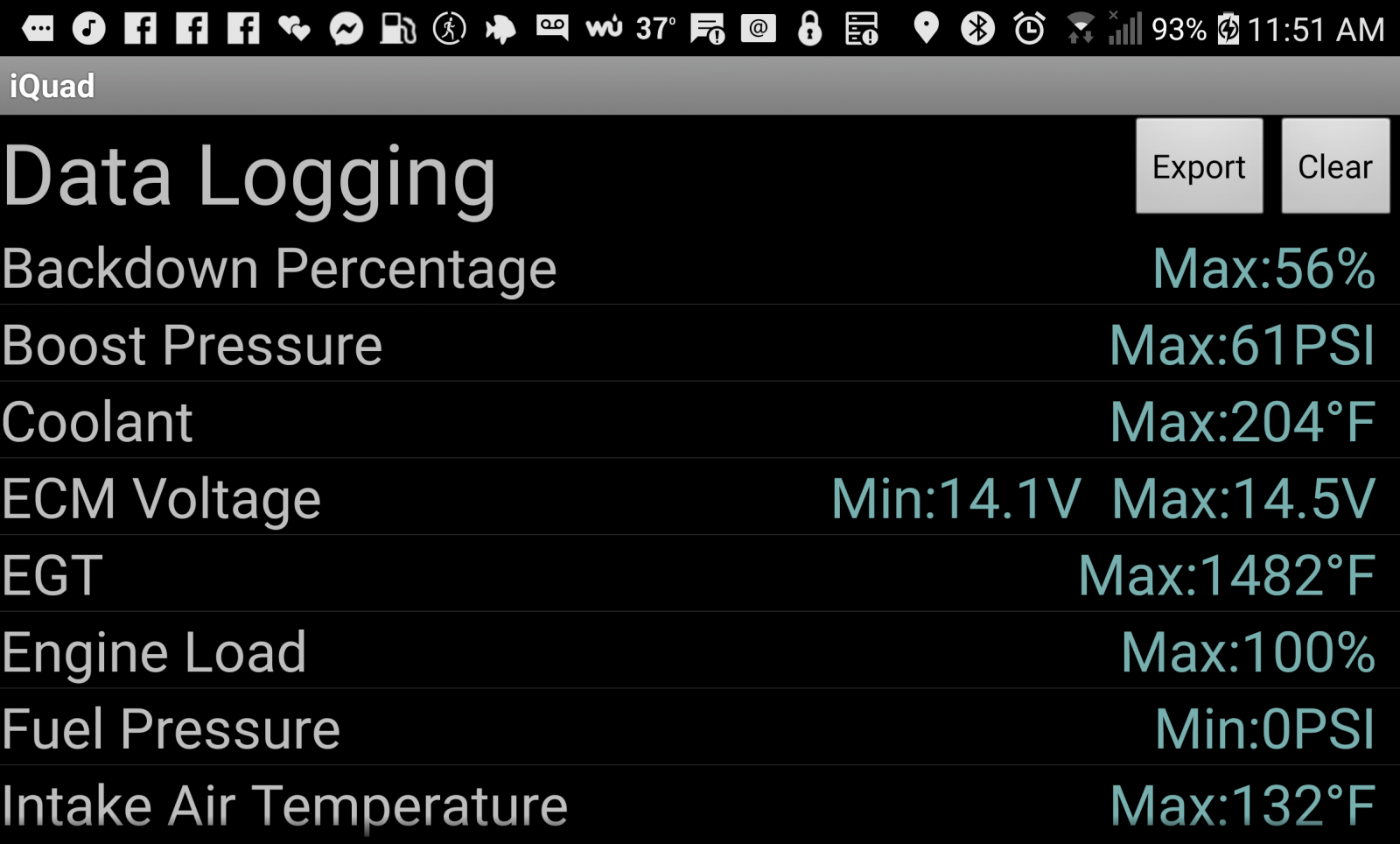

Yeah, I decided to check the WOT and boost pressure. Funny it reports my maximum boost pressure of 61 PSI. My ISSPro gauge shows barely 47 PSI maxed out running this gauge is correct. I know that this is all MAP sensor error. I figure I'd share this tidbit.

-

Map Sensor

Yes sir.

-

2001 Back-Up lights on all the time

Again simple. Just unplug the switch and see if the lights go out. If so the switch is bad. Pure and simple. 3157 bulb is not getting enough to light but still running current. LEDs just take much less current to light up. Since the switch is either open or close it seem the contact is lightly being pressed. Is the shift selector slightly out of adjustment?

-

Wait to start delay

Make sure to tag @pepsi71ocean about your experience with your rebuilder... Need to keep the data flowing.

-

Fuel Pressure High!

1/8 NPT to 1/8 tubing There is a reason for the remote mount. First, it moves the sensor to an accessible place. Now I can easily add a tee and hook up a test gauge and test for problems. The second, I wanted to get 5 foot or more of 1/8 tubing for suppression of the pulses. I've already seen what grease gun hoses do in the past which is pass the pulse through which does nothing why I figured out what I did. As for ISSPro Fuel Pressure gauge sensor it nearly 10-year-old now and never been replaced. Still working prefect.

-

2001 Auto Trans Fluid Change or Flush

Done that method a time or two for others...

-

2001 Back-Up lights on all the time

I still say switch is bad. Positive 12 volts will not jump a gap in ATF. I can see if the switch was ground and bleed being the entire transmission is ground. But +12V is not going to jump ATF and only to the reverse light. At any point electricity takes the easy path not one with resistance.

-

Getting ready to tow

Automatically handled with a Quadzilla tuner for the 2nd gen set the temp you want it keeps the truck running till the temperature is hit. Then it shuts down the engine for you. You can turn the ignition off and lock the truck and just walk away. I've got my Quadzilla set for 275*F. I wish the Smarty Touch for the CR engines had a cooldown timer. Sadly, it does not.

-

What fluid for the 47re Trans?

Ummm... That is why we all exist here on this website we can't leave well enough alone. We are always thinking and planning on how to improve what we have for a vehicle.

-

What fluid for the 47re Trans?

What I'm trying to point out there is a wide range of fluid people can use in transmissions (manual and auto). Just some people get way too hung up on fluid specs and fear of transmission damage. In either case the auto or manual all the parts are harden steel and bearings. Then the bands and clutch like syncros in the manuals. As long you understand what the requirements of the bands, clutch and syncros the door open up to a wide range of fluids you can use and viscosities and ratings. We are both in the modified transmission realm and using non-standard fluids and no problems. (Just make other members think)

-

Budget build, need advice

I'd be the first one with my multi-tool pulling the intake boot and looking at the turbo saying, "Naw, nevermind engine been dusted out... What else do you have?"

-

Tow Mirror Options

Thank for catching that...

-

Soft line transmission cooling line kit

Those Parker Push-lock fitting hold up pretty darn good!

-

What fluid for the 47re Trans?

What you don't like running transmission that is spec'ed for your 47RE transmission? Strange how NV5600 and NV4500 freak out about keeping spec'ed fluids in use. 47RE mix and match and go for it. If your 47RE it's modified it will run a wider range of fluids. Stock transmission I would have to suggest sticking to the ATF+4.

-

5 Speed Clutch Pedal Travel

While you are there look at everything if there is any wetness behind the master on the inside of the firewall or see any wetness in the pin side of the slave cylinder I would consider just replacing. I do not suggest the pre-bled system majority of the time people end up rebleeding the system all over not to mention you can save more on doing it yourself with separate master and slave cylinders.

-

Fuel Pressure High!

So is mine. ISSPro EV2. In my case just changing the fuel filter will push air back up the line. No issues even starting the system over completely dry. You see... Tap point, brass elbow, needle valve, ISSPro snubber, PTC fitting, then 5 feet of 1/8" air brake line back to the sensor above which is the brass sensor. With the PTC fittings, you can release the air brake line from the fitting to purge air if needed. Push down the collar and it releases the air brake line. Push the tubing back in and it self-locks and seals.

-

Wait to start delay

Make sure to test for the AC noise level out of the alternator. Then you want to do the W-T ground wire mod. While you there you might do the PCM protection fuse too.

-

Quadzilla tunes

I had to back down for efficiency reasons. 15, 18, 21, 25, 27... I notice with this the smoke level changed and was reduced. Still tears the tires loose in 3rd and 4th gear getting on the I-84. Watch the smoke if the smoke is on the top end then you most likely getting too advanced. If the smoke is down low you might need to add more timing. Even with 5* at 50% is a pretty good pull of power too. Dips the timing on a pretty good amount of retard and the boost builds quick enough the tires break free. This gives you 2.5* of retard. @trreed settings give 3.75* of retard.

-

Choosing The Right Fuel Lift Pump For My Needs

-

Airdog problems... again...

@hex0rz Did you do the W-T ground wire mod? Have you checked the alternator noise level?

-

Head gasket replacement

As for me I got a fresh razor blade and scrapped all the junk off the deck of the block carefully. Using a Scotch-Brite pad to more or less buff out the rest of the deck. I could have gone this route as well or even with new head bolts. Knowing my game plan I opted to just get it done at that time and bite the bullet. Just don't forget about this weakness before you go upward on the Quadzilla and bigger injectors. It would really suck to do the head gasket then do it again because the bolts failed you. You're fine and safe with RV275's and Edge Comp with what you got.

-

2001 Back-Up lights on all the time

You are welcome...

-

PDC

Be aware that some other devices could be passing power across circuits. What you going to have to do is pull all fuses then one at a time socket a fuse and see what the test light does. This will remove power from all other circuit and allow for full isolation of power per circuit so you can figure out the issue.

-

2001 Back-Up lights on all the time

You could drive up on some blocks of wood or ramps and raise that side of the truck. Even a road ditch will work. A quick swap and be done.

-

2001 Back-Up lights on all the time

I'm going to bet it still the switch is bad. Power should not be present at the light socket. Switch should be open with no power. I would ohm test across the pins of the switch.