Everything posted by IBMobile

-

What is the "BEST" engine oil & filter to use and why?

Had one of those the other day. I was a service on an MBZ and talking to the customer about his car I asked him if he checked his oil level between oil changes. His answer was "That's what I pay you people for". Today I was in O'Reilly today and at the counter next to me a woman was buying a 5qt jug of synthetic oil. She asked the sales associate how long can she use the oil till she needs to change it. He told her 3,000 to 3,500 miles.

-

"A" pillar gauge mounting

No need to drill holes. Take the cover off the left A-post and there should be an opening between the left side of the dash and the body. You can run every thing through there.

-

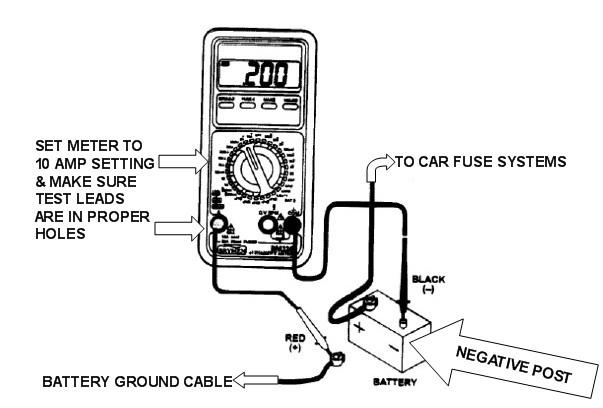

Battery charging question

-

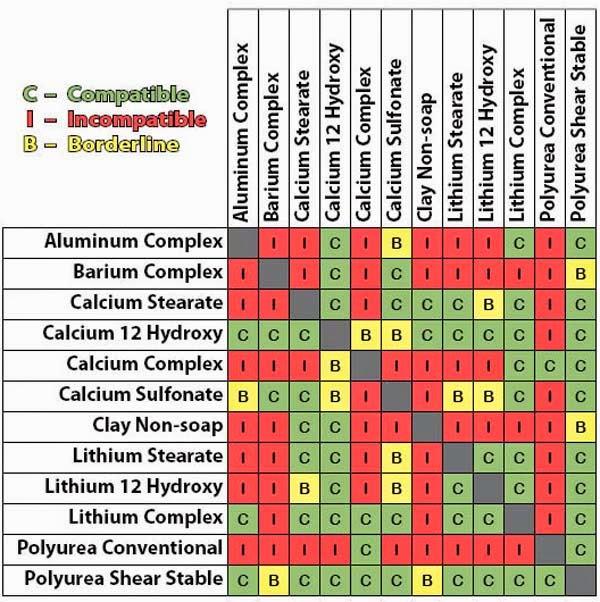

Mixing Grease

Mixing greases of the same or compatible base is no problem. If the grease base is not compatible then the lubricant oil can sperate or give no protection at all. When I can't determine what the grease base is I'll clean all the old grease off then apply new quality grease.. This is a compatibility chart for grease bases. The problem I run into is a lot of manufactures don't list the base type on the packaging.

-

Can I cover the AC dryer to protect from exhaust heat?

No problem with air flow. There is a minimum clearance between the filter and shield of 1" and that's only in a few spots. The rest is 2" to wide open. The engine can breath like a race horse at Santa Anita.

-

Can I cover the AC dryer to protect from exhaust heat?

Yes...Yes it is duct tape and it is the finest duck tape money can buy. Only the best for my truck. It was a little project I was trying out. I was making a heat shield for the BHAF out of the heat shielding that goes between a cars catalytic converter and the floor pan. This stuff works great, about 6 very thin aluminum layers sandwiched between two thicker sheets. 300°+ on one side and 95° on the other. The duct tape is to cover any sharp edges, then spry painter black. I took part of it off and ended with this. Yes that's my truck. It's gold over sliver. Under the hood is a dull gold. I haven't polished it yet.

-

Can I cover the AC dryer to protect from exhaust heat?

- Can I cover the AC dryer to protect from exhaust heat?

@Mopar1970man Why are you insulating the hot part of the pipe from the condenser to the orifice tube? I thought that you would leave that uncovered to let the heat escape like in the condenser. You would only need to cover the pipe from the orifice tube, after the pressure drop, to the fire wall/evaporator to keep the cold in.- is my vp44 shot

Blue Chip Diesel has the write up on trouble shooting the vp 44. https://www.bluechipdiesel.com/troubleshooting-1- Morning Pic For Today...........Post A Pic around your place.....

It's a snowflake entitlement mentality. "I'm in a hurry". "You're in may way", "Don't inconvenience me", "My time is more important than your time". It's worse at night and the weekends when they're not in school or work.- Windsheild sun shade

My wife says my breathes to much.- New A/C Compressor, Orifice Tube, and Accumulator, and now clutch wont engage.

I've used Murry A/C compressors from O'Reillys in a pinch. The last one I installed was for an 01 Chevy Taho with rear A/C, June 1, 2017. I paid $189 for it with a limited lifetime warranty. Here is a new Murry compressor from O'Reillys for $234. Now, that price is in Escondido, CA and I can't see why there is a $96 price difference between states. https://www.oreillyauto.com/shop/b/air-conditioning-16770/compressors---clutch-16796/a-c-compressor-12403/796587886e88?fitAttr_10076=With Clutch The other brands I've used have been Valeo , Sanden and York. These were for different Volvo models.- Can I cover the AC dryer to protect from exhaust heat?

Once the refrigerant is in a gaseous state the only way it can go back to a liquid is be compressed and sent through the condenser. A properly filled A/C system will not cause slugging. Over filled or filling the system with an inverted can will cause slugging. Insulating the piping after the orifice tube and before the evaporator is no problem. After the evaporator some auto manufacturer choose to insulate the accumulator. GM has done it with this products like this. https://www.ebay.com/p/A-C-Accumulator-Insulator-ACDelco-GM-Original-Equipment-15-10614/79416292?iid=282964073381&_trkparms=aid%3D222007%26algo%3DSIM.MBE%26ao%3D2%26asc%3D52475%26meid%3D84e53c92765446a885aca61308b093e9%26pid%3D100005%26rk%3D6%26rkt%3D12%26sd%3D161767073957%26itm%3D282964073381&_trksid=p2047675.c100005.m1851 Ford did it with a spray on insulation but it caused the accumulator made of steel to rust out, there was no way for the condensation to evaporate. Now they are made of aluminum. Mercedes covered the A/C lines in the 80's and 90's.- New A/C Compressor, Orifice Tube, and Accumulator, and now clutch wont engage.

See if this helps. .- Can I cover the AC dryer to protect from exhaust heat?

Heat always moves to cold, that's physics. So any part of the low pressure side of the A/C system from the expansion valve to the evaporator and accumulator is colder than their surroundings and will absorb the heat. This is extra heat that has to be removed from the system through the condenser. These 16 year old condensers aren't as efficient as when new so the system could use that added help of insulating the low pressure pipes, hoses and accumulator.- D80 ring and pinion

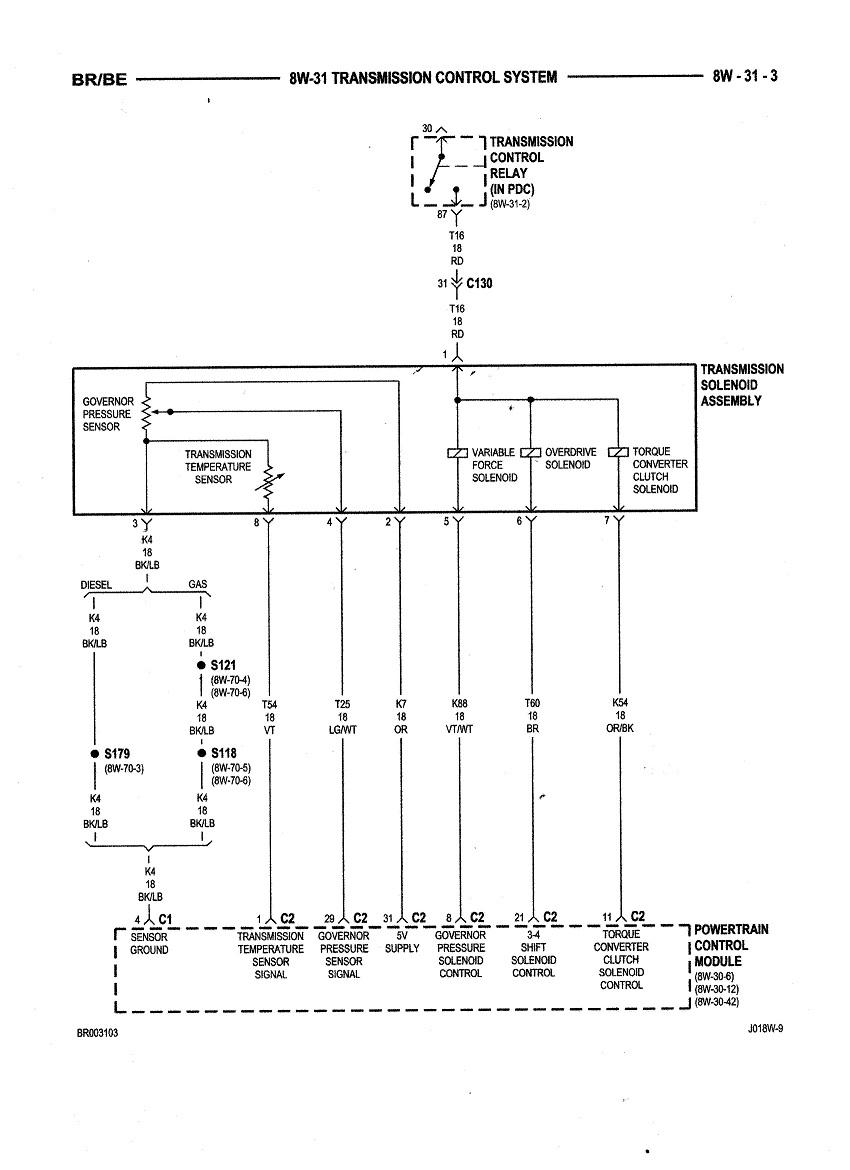

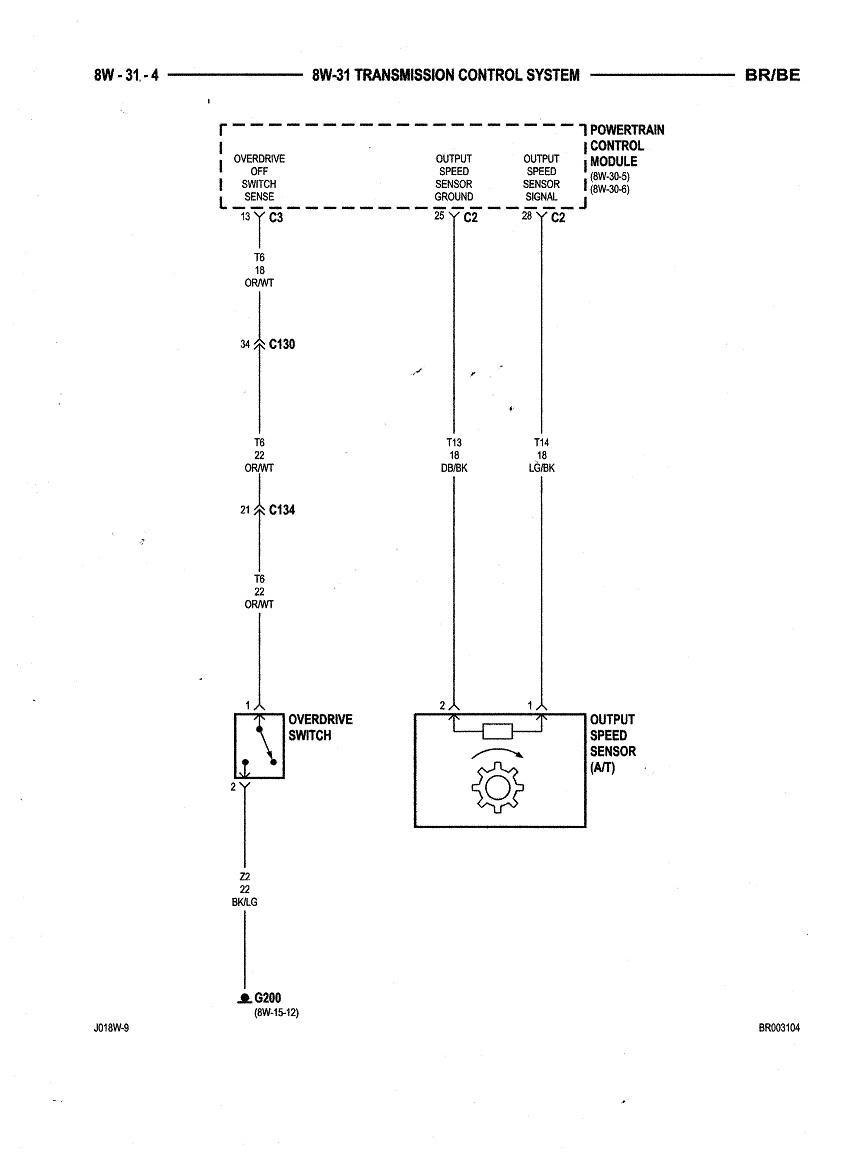

I'd take the cover off, spray it down with brake clean and blow it out, then refill. Cheap insurance, no need to have any thing going through the bearings let alone the ring and pinon.- 47re built transmission NO OD

- Cruise control Slow to Engauge

Well, I checked the vacuum system with a vacuum gauge and found that the vacuum was coming up very slowly and the vents would start to change at 6 in Hg and be fully opened at 8 in Hg. This took at least 30 seconds from start up and maximum vacuum was 10 in Hg. I disconnected the vacuum hose that comes from the vacuum pump at the fitting on the fire wall, installed the vacuum gauge and started the engine. The vacuum again rose slowly but as I moved the hose around a bit the vacuum would jumped up to 28 in Hg. So that tells me that the vacuum pump is working and there is a problem with the plumbing. Inspected the plastic hose and fitting to the pump and found the rubber the fitting is made from deteriorated. The fitting is now replaced with a 3" peace of vacuum hose. The vacuum now climbs to 28 in Hg in less than 5 seconds on start up. If you find one fitting that looks like this you will want to replace all the others because after 16 + years you know they'll be in bad shape too.- ABS or Divider

Had that happen on a work van with rear drum brakes. It turned out to be a sticking brake wheel cylinder on the right rear.- I’m a Newbie and need help

Here's how to make a relay mod if one doesn't come with the new pump.- Algae in Fuel

@CTcummins24V I run my edge on level 2 and @dripley is right about the boost. If it's towing or not the best boost I see is 30psi, that's what I set the boost controller at and I don't think my HX turbo would produce much more than that. I normally drive 65-70 and tow at 60-65 mph, the boost is 0-5 psi when cruising.- Algae in Fuel

Right, It's a 24 micron stainless steel mesh fuel strainer used pre-pump. It is not a fuel filter. I think I'll get one for my Fuel Boss system.- Algae in Fuel

Do you have an electrical back up fuel pump with that Fuel Boss. If so you could add a fuel line to the system, energize the pump and have it fill 5 gallon fuel cans or stick a hose in to the tank filler neck and siphon it out.- Well the Order is in

That's the 4th of July. You think some Auto Workers Union wonk is going to be there for less than triple time?- Fuel pressure alarm 10 psi

You may need to make your own set up. It would be easy to do with a fuel line T-fitting with an adjustable hobbs pressure switch like the one that is supplied with the Fuel Boss lift pump. This set up is used to turn on and off the back up electric fuel pump and can be adjusted to any pressure you want.. In stall an LED light like the one below in place of the fuel pump. By the way, 10PSI is to low. You want fuel to run through the pump and back to the tank to keep the pump cool. The return line valve doesn't open until 14PSI so you will want to set it for 13PSI.. LED light http://www.ebay.com/itm/like/311818045237 hobbs pressure switch https://www.ebay.com/sch/i.html?_nkw=hobbs+pressure+switch - Can I cover the AC dryer to protect from exhaust heat?