Leaderboard

-

- All areas

- Events

- Event Comments

- Files

- File Comments

- File Reviews

- Images

- Image Comments

- Image Reviews

- Albums

- Album Comments

- Album Reviews

- Blog Entries

- Blog Comments

- Cummins Articles

- Cummins Article Comments

- Cummins Article Reviews

- Vendors

- Vendor Comments

- Vendor Reviews

- Ads

- Ad Comments

- Ad Reviews

- Policies

- Policy Comments

- Topics

- Posts

-

-

dripley

Retired Staff4,586Points11,788Posts -

Dieselfuture

Yearly Subscription2,150Points5,783Posts -

Tractorman

Yearly Subscription1,091Points1,543Posts -

dorkweed

Retired Staff588Points1,751Posts

Popular Content

Showing content with the highest reputation since 12/14/2009 in Posts

-

Truck stolen

17 pointsGot it back tonight... man it feels good to drive it again. Handed it off to my dad and he's got it locked up in the shop. Insurance adjuster should be out soon to assess the damage and stolen items.17 points

-

Important MessageTo all forum Members

14 pointsHappy Thanksgiving to all you guys and your families. But most especially to MoparMom who is such a key ingredient to this Forum. After all she raised a great son who has helped so many of us to keep our trucks going long and strong. I send her my love and hope more of you all get the opportunity to meet her Thanks to all you guys for all the helpful fun posts..14 points

-

Most amazing mod I've ever made to a 2d gen... a new cupholder.

The cup holder from Geno's worked great ....... no complaints! But, this console from a 2011 Dodge works better. Easy to install. The back two mounting holes match up, just drill into the mounting frame for the front two. Sits a little lower than the original, has a little less room, but opens easier and has the electrical 'ports' ..... and a lower compartment below the seat cushion. And again ...... because of the lack of spilled coffee, I'm getting younger, have untold wealth, and never get flat tires!14 points

-

My SON!!!!!

14 points

-

Letter from an airline pilot:

14 pointsHe writes: My lead flight attendant came to me and said, "We have an H.R. On this flight." (H.R. Stands for human remains.) "Are they military?" I asked. > > 'Yes', she said. > > 'Is there an escort?' I asked. > > 'Yes, I've already assigned him a seat'. > > 'Would you please tell him to come to the flight deck. You can board him early," I said.. > > A short while later, a young army sergeant entered the flight deck. He was the image of the perfectly dressed soldier. He introduced himself and I asked him about his soldier. The escorts of these fallen soldiers talk about them as if they are still alive and still with us. > > 'My soldier is on his way back to Virginia ,' he said. He proceeded to answer my questions, but offered no words.> > I asked him if there was anything I could do for him and he said no. I told him that he had the toughest job in the military and that I appreciated the work that he does for the families of our fallen soldiers. The first officer and I got up out of our seats to shake his hand. He left the flight deck to find his seat. > > We completed our pre-flight checks, pushed back and performed an uneventful departure. About 30 minutes into our flight I received a call from the lead flight attendant in the cabin. 'I just found out the family of the soldier we are carrying, is on board', she said. She then proceeded to tell me that the father, mother, wife and 2-year old daughter were escorting their son, husband, and father home. The family was upset because they were unable to see the container that the soldier was in before we left. We were on our way to a major hub at which the family was going to wait four hours for the connecting flight home to Virginia .> > The father of the soldier told the flight attendant that knowing his son was below him in the cargo compartment and being unable to see him was too much for him and the family to bear. He had asked the flight attendant if there was anything that could be done to allow them to see him upon our arrival. The family wanted to be outside by the cargo door to watch the soldier being taken off the airplane. I could hear the desperation in the flight attendants voice when she asked me if there was anything I could do. 'I'm on it', I said. I told her that I would get back to her.> > Airborne communication with my company normally occurs in the form of > e-mail like messages. I decided to bypass this system and contact my flight dispatcher directly on a Secondary radio. There is a radio operator in the operations control center who connects you to the telephone of the dispatcher. I was in direct contact with the dispatcher. I explained the situation I had on board with the family and what it was the family wanted. He said he understood and that he would get back to me.> > Two hours went by and I had not heard from the dispatcher. We were > going to get busy soon and I needed to know what to tell the family. I sent a text message asking for an update. I Saved the return message from the dispatcher and the following is the text:> > 'Captain, sorry it has taken so long to get back to you. There is policy on this now and I had to check on a few things. Upon your arrival a dedicated escort team will meet the aircraft. > The team will escort the family to the ramp and plane side. A van will be used to load the remains with a secondary van for the family. The family will be taken to their departure area and escorted into the terminal where the remains can be seen on the ramp. It is a private area for the family only. When the connecting aircraft arrives, the family will be escorted onto the ramp and plane side to watch the remains being loaded for the final leg home. Captain, most of us here in flight control are veterans.. Please pass our condolences on to the family. Thanks.'I sent a message back telling flight control thanks for a good job. I printed out the message and gave it to the lead flight attendant to pass on to the father. The lead flight attendant was very thankful and told me, 'You have no idea how much this will mean to them.' > > Things started getting busy for the descent, approach and landing. > After landing, we cleared the runway and taxied to the ramp area. The ramp is huge with 15 gates on either side of the alleyway. It is always a busy area with aircraft maneuvering every which way to enter and exit. When we entered the ramp and checked in with the ramp controller, we were told That all traffic was being held for us.> > 'There is a team in place to meet the aircraft', we were told. It > looked like it was all coming together, then I realized that once we turned the seat belt sign off, everyone would stand up at once and delay the family from getting off the airplane. As we approached our gate, I asked the co-pilot to tell the ramp controller we were going to stop short of the gate to make an announcement to the passengers. He did that and the ramp controller said, 'Take your time.'> > I stopped the aircraft and set the parking brake. I pushed the public address button and said, 'Ladies and gentleman, this is your Captain speaking I have stopped short of our gate to make a special announcement. We have a passenger on board who deserves our honor and respect. His Name is Private XXXXXX, a soldier who recently lost his life. Private XXXXXX is under your feet in the cargo hold. Escorting him today is Army Sergeant XXXXXXX. Also, on board are his father, mother, wife, and daughter. Your entire flight crew is asking for all passengers to remain in their seats to allow the family to exit the aircraft first. Thank you.' > > We continued the turn to the gate, came to a stop and started our shutdown procedures. A couple of minutes later I opened the cockpit door. I found the two forward flight attendants crying, something you just do not see. I was told that after we came to a stop, every passenger on the aircraft stayed in their seats, waiting for the family to exit the aircraft. > > When the family got up and gathered their things, a passenger slowly > started to clap his hands. Moments later more passengers joined in and soon the entire aircraft was clapping. Words of 'God Bless You', I'm sorry, thank you, be proud, and other kind words were uttered to the family as they made their way down the aisle and out of the airplane.> > They were escorted down to the ramp to finally be with their loved one. > > Many of the passengers disembarking thanked me for the announcement I had made. They were just words, I told them, I could say them over and over again, but nothing I say will bring back that brave soldier. > > I respectfully ask that all of you reflect on this event and the sacrifices that millions of our men and women have made to ensure our freedom and safety in these USA , Canada , Australia New Zealand, England .> > Foot note: > > I know everyone who has served their country who reads this will have tears in their eyes, including me. > > > They die for me and mine and you and yours and deserve our honor and respect.> > 'Lord, hold our troops in your loving hands. Protect them as they protect us..bless them and their families for the selfless acts they perform for us in our time of need.. In Jesus Name, Amen.' > > GOD BLESS YOU!!!14 points

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

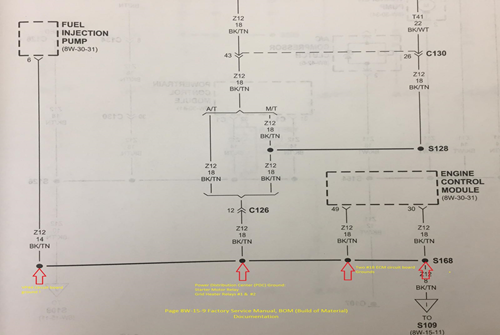

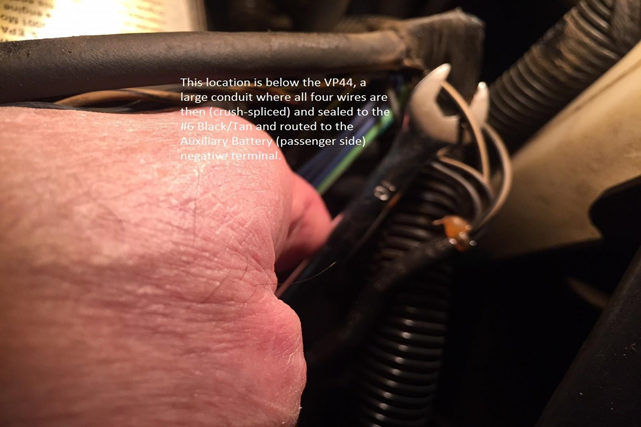

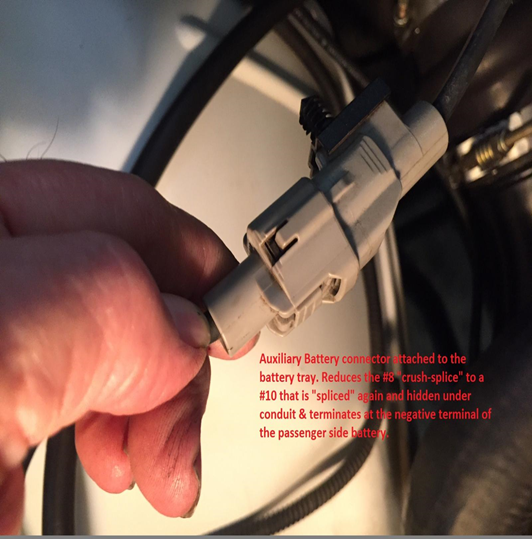

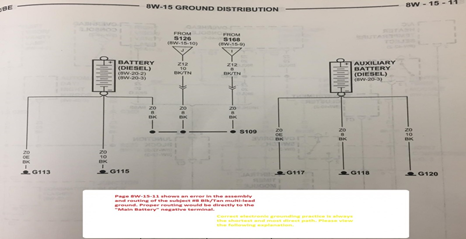

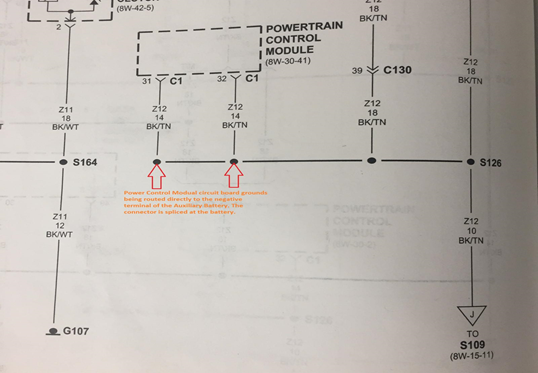

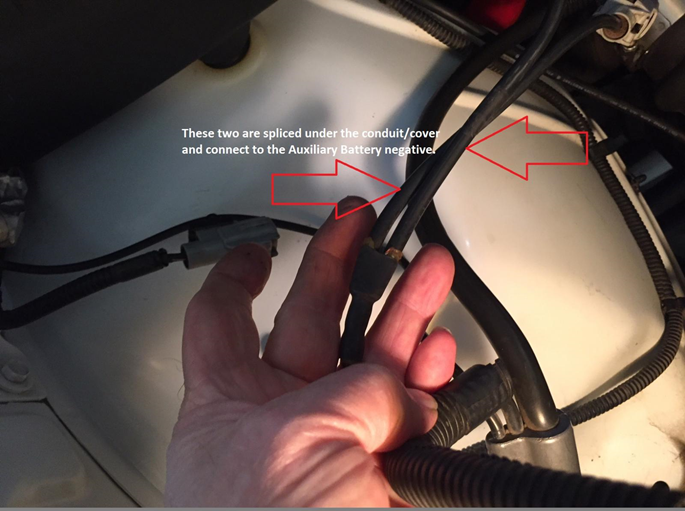

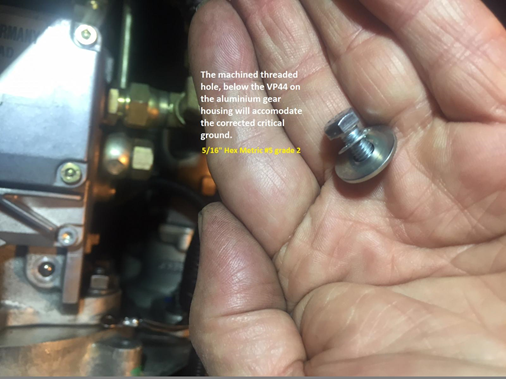

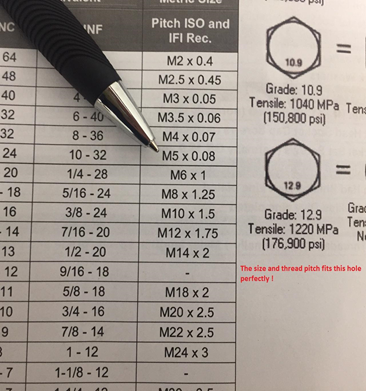

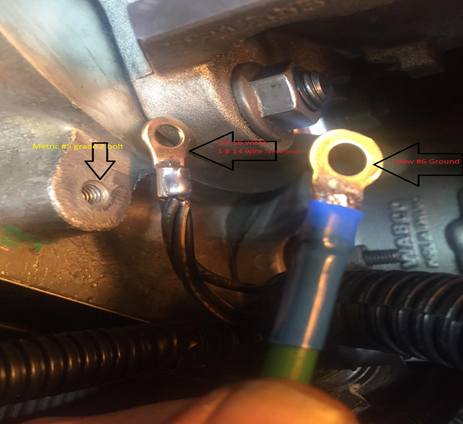

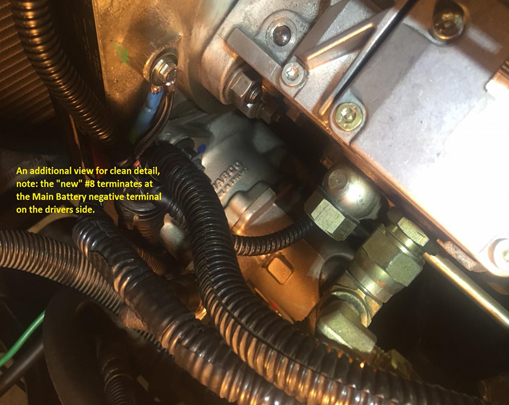

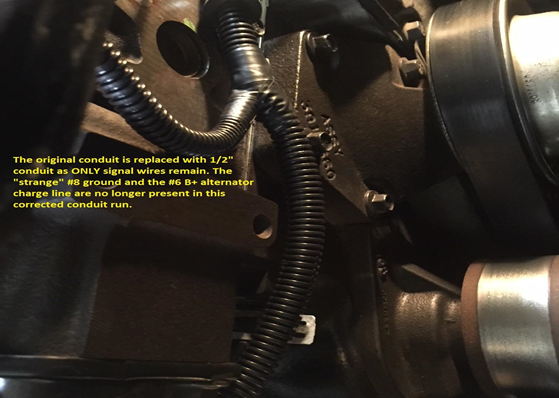

After 18 years of interesting CTD enthusiasts and transmission specialty outlets all contributing their method, or fix, to the well known TC lock unlock syndrome, I can no longer remain silent. Extensive review of many posts regarding TC lock unlock, the rerouting methodes, the add on filters for APPS and last, but not least,...the "tin-foil hat" brigade. I do realize that each individual or company that contributed to the vast amount of information on the web had good intentions and I must acknowledge that some of the procedures caused me to closely examine what these people were trying to do. I believe it is well known that even a blind mouse occasionally finds a morsel of cheese. Again, as it is well known @Mopar1973Man was the only entity who positively identified the instigating source of this key issue. My entry today is not about alternators...it is about what Daimler/Chrysler did in regard to production of these Cummins powered platforms and the complete disregard of common sense Electronic Engineering. Please note, this applies to automatic and manual transmissions as each platform is plagued in the same manor with different quirks. This Blk/Tan #8 gage wire is quite critical in the scheme of things. It is contained within a 1" plastic conduit passing along the front of the engine. It contains water temp sensor leads, air conditioning leads, alternator/PCM leads and the #6 gage alternator charge line to the PDC. This #8 gage Blk/Tan passes over the top/backend of the alternator and is "eventually" connected to the Auxiliary Battery (passenger side) negative terminal. This snapshot of the Factory Service manual documents "four critical ground leads" that are "spliced" in an unconventional method. This photo depicts the three #18 gage wires and the single #14 gage wire entering the shrink-tubing where the "crush-splice" occurs. This bundle exits the large plastic conduit below the VP44 This again is a most disturbing depiction of the Daimler/Chrysler method of splicing critical ground leads and then routing this across the top of the alternator and "eventually" bringing this to ground reference. This photo depicts where this #8 gage Blk/Tan first connects on the way to "eventual" ground...yes this is the Auxiliary Battery tray connector. Please note: it is spliced again and joins the PCM circuit board grounds...which are critical in their own nature...and "eventually" terminate at the negative post of the Auxiliary Battery's negative terminal. This photo is very interesting, it is the Factory Service manual and the assembly line documentation follows this as a road map in the matrix during production. Please NOTE the title "NAME" to each battery...I looked at this for a considerable amount of time before I realized the assembly line coordinators tried to work with the documentation from the Engineering Staff to "make it as it looks"...Could this single oversight be the reason of a four foot ten inch critical ground wire combination traveling the distance to "EVENTUALLY" terminate at ground? From a basic engineering standpoint regarding ground...you "NEVER CHOOSE THE PATH OF EVENTUAL GROUND" !!! It is to be the shortest and most concise connection in reference to ground...this is biblical in ALL ELECTRONICS...including pickup trucks. ! Here is the Factory Service manual documenting the PCM circuit board reference ground starting as a pair of #14 gage wires being spliced into a #10 gage bundle and arriving at the Auxiliary Battery through another connector that joins a #8 gage wire that is "splice-joined" under plastic conduit in a Y configuration joining the rouge #8 gage "after passing over the alternator" traversing the entire engine compartment from the driver side of the vehicle. Seriously I have been drinking excessively, most recently, due to the nature of this blatant discovery. This is the hidden Y splice at the Auxiliary Battery where the "mess" EVENTUALLY terminates for ground reference. This photo shows the correct "HOLE" of where to apply ground for the VP44, ECM and the PDC...note the logical location It took a little research to find the size and proper thread-pitch. Metric M5 with a 5/16" hex head is perfect This is where you apply a fresh "quality" #6 gage ground and terminate this at the Main Battery negative post on the drivers side for absolute ground reference for the VP44 and ECM This is a very short and concise reference to ground. This is the corrected procedure for a rather critical ground. The two largest wires originally contained within the 1 inch conduit are no longer present and located well away from the alternator. My alternator B+ "charge" line is now a #4 gage line directly connected to the Auxiliary Battery and when my new battery terminals arrive and they are secured, I'll provide photos of a completed Master Power Supply System within this engine bay. With these corrections, I would hypothesize that a poor ripple specification on a given alternator would be overcome by the immense capacitance of the parallel batteries and would become less prone to causing the dreaded TC lock/unlock for automatics and cruise-control abnormalities for the manual transmission platforms. The #8 gage Blk/Tan passing over the alternator as an "EVENTUAL" ground is gone...the PCM, ECM, VP44 and the PDC are now grounded in accordance of standard Electronic Engineering practices. Respectfully W-T12 points

-

Blue and Black haired angel

11 pointsJust have to brag on Mike. Many don't realize just what kind of human being he is. We were just in Winco doing some shopping. We were waiting in line to check out when this little old lady was trying to pay for her groceries...her card was not working...she was almost in tears. Mike paid for it, $269 worth. He simply told her Merry Christmas. The woman was in tears....he is such a kind heart. He struggles to make his own bills every month, and still did this. I'm in tears writing this...11 points

-

Preparing for road trip.

11 points

-

The moment you've all been waiting for "SPORT/QUAD HEADLIGHT CONVERSION"

OK Guy's.."The moment you've all been waiting for" Here is a complete start to finish Details on Converting Standard 2-headlight system to a Sport Quad headlight sys. i did a few months ago Let me tell you it was a P.I.T.A...i had nothing to go on as none of the threads i found on any of the forums involved building your own from scratch "w/Heavy Duty Stuff" ..most of the write ups were people who had bought a pre-wired harness..like the ones for example suvlights.com or others..all reported problems either "fog lights staying on..lights would not turn off, lights would not come on or lights were dim on bright, etc... So not finding any information in relation to a possiable wiring diagram i purchased a "pre-made harness w/relays from LMC..What a piece of shi$$..i mean lets totally forget that it did not work,{ lights went out or "almost out on Dimm}...this was chineese junk a frigg'n fire hazzard. .cheap light gauge wire i could bite into. connectors that "pulled out after unplugged a time or two..and last but not least.."NO SOLDERED CONNECTIONS, ALL CRIMPED AND "NO HEAT SHRINK. See none of these aftermarket harness's will work on these Trucks neither the Chinese "JUNK" nor the other decent harness's...."WHY" you ask... ..Because no one { that i was able to find } has been able or have taken the time to "Crack This system" and build a precise fit "PLUG AND PLAY" HARNESS ". The 2nd GEN Dodges have a ODD wiring system, I Call it {for lack of a better term} Ground Switching System because thats what it does. It switches the ground Neg- instead of the POS+.. The original wiring has a hot wire to Headlight plug that HOT 24/7..all the time. SO..after tryin to get around it..I started designing & building my own system. and with much help from..MICHAEL "MOPAR MAN" i eventually completed my own system.."NOW..Im passing this information on to you guys because the lights on these trucks "SUCK"..and this is an Awesome improvment that....well ..you will have to see for your self.....AND......I DONT WANT NO ONE TO GO THRU WHAT I WENT THRU BUILDING MINE ..L.M.A.O. ***note*** I soldered all my connections & used heat shrink tubing to make a moisture free system. I also harnessed all the wires in split wire loom conduit thanks Michael Check out link below: Slideshow http://s1209.photobucket.com/albums/cc389/rburks1/Dodge%20Sport%20Quad%20Headlight%20Conversion/?albumview=slideshow Pictures http://s1209.photobucket.com/albums/cc389/rburks1/Dodge%20Sport%20Quad%20Headlight%20Conversion/ Below is the Parts list complete with part numbers & prices. except for the fuse holders, I got most all parts from you can find these parts at most auto or electronic's stores and they don't have to be these brands either but i suggest using quality relays w/holders to make replacement easy. COMPLETE PARTS LIST for HD HEADLIGHT HARNESS (sport HL) ***note*** This Parts list is for reference only.. Vendor, Manufacture & Brands are open to your preference 2-male headlight connector (same as bulb)............................................#CP9004CM..............7.49ea. 2- Ceramic female 9004 Connectors #CP9007CFC.............7.49ea 2-Ceramic female 9007 Connectors.......................................................#CP9004CFC.............7.49ea . 4-HELLA SPST Relays, 40A, Dual 87 outs, .............................................#HL87483...............8.00ea. **Option** 4-SPST HELLA Relays, 40AMP, Dual 87 outs, with Diode.............................#HL87753..........13.00ea. NO LONGER AVAILABLE **Option** 4-SPST HELLA Relays, 30AMP, Dual 87 outs, with Diode..............................#HL87453..........8.00ea. Available @ ralleylights.com ****** Note******* It is not mandatory to use the ones with diodes or resistors, it just helps insure safety for stereo sys, CB & The entire electronic system from EF Feedback.. You could use 30amp relays as you are using separate low and high beam circuits. In the beginning i was originally trying to use only 2 Relays, 1 on each side. I found out later this to be "IMPOSSIBLE" . YOU MUST HAVE 4-RELAYS.. You can use ones with single 87 out and wire together,, the Dual 87 out just makes a nice clean wiring system and i hat cobbled up wiring 4-Relay Holders, complete with terminals....................................................#HL87123.................3.77ea. I Strongly recommend using Holders, it will make changing a relay out as easy as changing a fuse if you should ever have to I got the fuse holders from Advance Auto....."Bussmann Inline, 12ga. wires............#BP/HUU...................5.49ea. I got the Dodge OEM Sport Headlight assembly's @ http://www.factorymopar.com they are a Dodge dealer with online OEM parts. there prices are way below local Dealership. Sport Headlight Assembly's : price= 233.64.. left side 225.38 ..right side There are Cheeper Options for the The Sport Headlights but be forewarned of the cheap knockoffs and there problems like "leaking", , not very good fitment or alignment, ,poor quality Adjusters that make adjustment difficult or impossible>>> "This is important cause you will have to dial these in and insure the Beam is to the left on LOW BEAM Driver side as to keep from blinding oncoming Cars. "The OEM Lights are pretty close out of the box ".. A salvage yard would probably be a good source if you could find any thats not damaged. **UPDATE PLEASE READ ** I have had several Guys PM me asking why is it that there HB indicator light stays burning even on LB...most of the time this issue is caused by wires being in wrong location on one of the Headlight plugs . A weak GROUND circuit will also cause this, You have to have a solid -GND circuit to the Headlight connectors. I used the spare Side post Terminal's on my OPTMA RED TOP BATTERIES POS+ & GND - post. BUT: There is a Post on front inner fender just below the Battery, there is a Solid 8# wire that runs from there that goes to Neg- post battery terminal on battery so this is as good as going straight to Neg without having a bunch of wires hanging off of your Battery causing mores battery issues in the future.. But first be sure it is solid and clean,, if not solid and free from corrosion then replace it. The other cause would be that you have a wire in the wrong place on the back of one or more H L connectors or in the conversion plug itself. Dodge sport Quad headlight conversion.doc Dodge Sport Quad Headlight Conversion- Relays.doc11 points

-

Big change in my life...

11 pointsAwesome news. My right kidney is healing. Ultra sound shows is not as swollen and there is hope. No surgery required today.11 points

-

Head gasket blown - Coolant leak

11 pointsMike, Truly my pleasure! You do more for people with no expectation of anything in return than 99% of the people on this planet. I have not always been in a position to financially help others in my life but I am currently blessed enough to do so and helping someone like you is a given in my world. I talked with others here after I spoke to the machine shop and I think others would like to participate in helping you in a tight/tough time. I don't see you as one looking for handouts but maybe we could set something up on the website for others who feel as I do about you and the value of the site. I wish I could have paid that whole bill for you, you always answer with Grace my dumbest of questions and have helped me and I am sure many others here through the simple and tough questions. I ask all members that Mike has helped save $20-$1000'S to pay it forward. Many small contributions will make a BIG difference. Mike I ask that you recommend that machine shop to any and everyone in your area!! Great group of guys to help me. If I need a head rebuilt I might just ship it to them. Happy to be able to help a man who has helped me directly and indirectly more than he will ever know. THANK YOU MIKE!! Brian11 points

-

Full Color Wiring Diagrams!

11 pointsHere you go gang! I compiled a full wiring diagram PDF file for you to all enjoy for your 2002 Dodge Trucks. This is a heck of alot easier to read compared to the Dodge FSM manual that is just good old black and white. Go here to get it! https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/electrical/11 points

-

Ground Reference VP44,ECM,PCM,PDC plus TC lock/unlock

Part 2 I wish to apologize for my absence and attempt to clear some of the stress I may have created. Members @GSP7 and @Dodgeih, my humble and sincere apologies. My thanks to Nick @Me78569, @syndicateshop, @IBMobile, @RipnRam99, @dripley and @JAG1 for filling in the blanks during my absence regarding this lengthy posted subject matter. I'm nearing retirement and I'll be more expedient in the near future. This thread is a focus to remedy the tragic TC Lock/UnLock syndrome and it does tie into the alternator issues bestowed to all 2nd Gen CTD owners. The Godfather @Mopar1973Manis the one who deserves the recognition in this thread. The following photos should suffice in rendering clarity to the "procedures" required to accomplish the the task. Please NOTE: the methods applied are Electronic Engineering standards for high-current demands with ABSOLUTE references to GROUND. The excursions are ONLY for balance (equalization) between two storage batteries in a parallel configuration. This is DONE to allow the Battery Temperature Sensor located on the Main Battery tray (driver side) to be accurate during charge-rate intervals for both batteries. This is accutley important when higher current Alternators are placed into the system. I must emphasize the reasoning: The two batteries are physically separated in distance to accommodate the given engine bay and the Daimler/Chrysler budget to produce the CTD platform. Perfection or "the correct way of doing it" was NEVER a consideration of the manufacturer. I do not wish to continue harping on their oversites...this is what should be done in following the opening portion of this thread. This photo depicts the correct 4 gage conductor directly terminated at the Auxiliary Battery positive terminal. @IBMobile has completed this step and documented his work. This photo documents the "direct" ground from the PCM and fender-ground terminated at the Auxiliary Battery negative terminal. @dripley is very correct in mentioning the "least" amount of connections (splices) should be observed. @IBMobile also accurately documents the "hidden crush-splice" in the wire loom near the PCM where this PCM ground originates. To be a purist, opening this conduit and directly replacing this ground lead with a "clean" 8 gage (or 10 gage) and bringing this directly to the negative terminal would be the best practice. This photo depicts the additional 2/0 Gage lines that "absolutely" strap both storage batteries into compliance of equalization. Again, this excursion (not originally documented in the opening thread) is done for ABSOLUTE integrity between the two storage cells. The "charge" rate from the Alternator supplying the Auxiliary Battery is absolute and mirrored at the Main Battery tray temperature sensor for accuracy. Again, this is most important for those who elected to upgrade the Alternator platform to a higher current device. I would encourage anyone applying this general modification to at least provide, one additional ground strap between the Auxiliary and Main Battery. Do not assume the two 0 gage ground leads to the engine block to provide absolute "ground reference" between the two storage batteries, even, if you remain with the "stock factory" Alternator. The direct 4 gage B+ charge line supplies the Auxiliary Battery first and is in parallel with the Main Battery...the engine block is ground however: for ABSOLUTE ground reference between the two storage cells you should strap an additional ground. The temperature sensor at the Main Battery tray relies on "equalization" between the two cells for sinusoidal charge rates. This photo depicts the Main Battery lines and their perspective terminations. The only excursion here is the replacement of the Starter Motor 2/0 gage supply line. I didn't like the ugly factory line from the front mounting location. This line comes up from the back of the firewall and passes below the PDC box...it certainly cleans up the appearance and provides added accessibility below the VP44 and vacuum/power steering components. Changes like this provide additional serviceability with an artistic flare. This photo depicts the left front fender ground location that terminates at the Main Battery negative terminal. The ugly factory "lug" and sheet metal screw has been replaced with brass components. All connections are below the fender-lip and all paint was removed (Dremel tool grinder) to provide a corrected high-current ground point. Below this connection point are two rather large grounding posts that need attention. The large amount of grounding lines in this corner require some TLC, the method I used provides integrity for DC ground and cleans up the crude slipshod procedure. Besides...mine looks pretty. I should also mention, the brass-to-body connection is treated with conductive grease to eliminate any dissimilar "metal-to-metal" corrosion. @JAG1 has procured the best copper-conductive product available for such purposes and I've not been able to con him out of a few ounces yet. This photo depicts the elected components selected for the heavy current demands in this project. All 2/0 gage line is flexible copper Welding stock...it is very nice to work with and I purchased a modest 12 ton hydraulic "crimper" to apply all zinc-coated connectors as terminations. All shrink-tubing is 3M with internal adhesive for moisture incursion prevention. These beautiful Orion battery connectors provide a very convenient sevicability aspect. Please NOTE the Grid Connection point. Removing the protective caps to expose the connector is very easy ! This is done with Mike @Mopar1973Man in mind to allow the Grids to be disabled for the summer time conditions where Grids are not required. A small Allen wrench is all that is required and can be performed in less than one minute.This photo depicts the graceful run of four 2/0 gage lines across the top of the radiator and artfully draping into position.This depicts a correct Parallel DC storage Battery system created with serviceability in mind.This completes the creation of a DC Power supply worthy of the Cummins platform. The new DC Power Engineering XP270 Alternator with corrected DC ground lines and complementary strapping is exemplary. The performance of a cold morning start was impressive as the Grids fired sequentially without a hint of stress. The "stiff" DC current supplied by the XP270 mimicked a full military hardened assault vehicle under load. I couldn't be more pleased The test drive under warm road conditions yesterday afternoon with particular attention to speed and road conditions showed NO TC lock/unlock syndrome...again win/win. I conclude this saga in humble reverence of the Cummins Turbo Diesel Fraternity in a sharing gesture for all disciples. Cheers, W-T11 points

-

At my freinds tranny shop

11 pointsSadly, many "built" valve bodies are simply pre-"shift kitted" bodies. And, yes, a "shift kit" will raise your line pressure a bit, and firm up the shifts. That's actually the super easy part. Guys will "kit" their valve body, feel the shifts a little more positively than they did before, and drive off satisfied. And, if that was your goal, then mission accomplished... But these transmissions need quite a bit more pressure than simply putting in a heavier PR spring will give you. This is especially true when guys are using tuners and "chips" to bump their power. While these products are great, and work well, what ends up happening is that your engine will make significantly more power for a given amount of throttle pedal travel that it did with OEM calibrations alone. So, as a result, you end up doing all of your daily driving (your non-"spirited" driving, if you will) with significantly less throttle applied than before. The thing is that your transmission relies on throttle pedal travel (read TV cable movement) to adjust its operating pressure to handle the torque being applied to it. So you end up with a line pressure to torque ratio that is far from favorable. The stiffer PR springs that come in "shift kits" are a step in the right direction in that they do boost line pressure, but it's not nearly enough to reliably handle what you're asking it to do. Developing an optimal pressure curve requires, first of all, an understanding of how these valve bodies control pressure, which is different than pretty much anything else in the transmission world. But suffice it to say that manipulating the hydraulic signals that act on the PR valve is where all of the magic happens in a well built custom valve body. There are several ways to do this, depending upon your end goal, but that's what is necessary to achieve a really good pressure curve. Once you achieve a desirable pressure curve, you will need to deal with the shift and lockup calibrations. If you tried to use stock shift calibrations with an optimal pressure curve, it would, at the very least, be quite unpleasant to drive. Specially designed separator plates with substantially undersized calibration orifices are really the only solution to this dilemma. Again...stuff that a "shift kit" doesn't address. As far as other things a "shift kit" won't give you (at least in a 47RE, which is what we're discussing here), the list would include: ability to lock the converter in any forward gear (including manual 2nd), ability to perform a locked 4-3 downshift, performing an earlier and more positive 3-2 downshift, some cooling and lube control mods, revised boost valve strategy, etc... Why don't I like Transgo in the Chrysler VB? A few reasons... Reason #1: biggest in my book is that they have you grind the land on the switch valve, which effectively removes its ability to regulate converter charge pressure. This is most significant at high throttle settings in reverse, where pressures can easily exceed 250 psi, especially with the stiffer spring you just put in there. This can (and does) balloon torque converters. Reason #2: I don't at all care for the way that they reverse the function of the OD accumulator, and then give you their crappy springs to put in there to try and control OD apply. Personally, with the right calibrations, I find it much easier to control OD apply (especially at high throttle settings) with the OEM style hydraulic accumulator. Reason #3: they remove the function of the part-throttle portion of the 2-3 valve train. This auxiliary portion of the valve body removes TV oil from the 3-2 valve train once a certain amount of governor pressure (road speed) is achieved. I prefer to leave this active for driveability reasons. Reason #4: their manual valve is not nearly as effective as others on the market. I simply do not care for their manual valve. Superior's valve is the best on the market, in my opinion... Sorry for the novel...11 points

-

Took a moment to play in the snow today

11 pointsPicture secretly taken this afternoon of Wild and Free moving snow.11 points

-

Prayers Please for MoparMom

11 pointsShe made through her surgery last night. Doing good this morning.11 points

-

Moving to almost the great white north.

10 points10 points

- Milestone

10 points10 points- Moving to almost the great white north.

10 points- Moving to almost the great white north.

10 points- coronavirus protection

10 points- 2001 Ram 2500 complete interior restoration

Hey folks, I haven't posted in a while but i've been around tinkering with 2 out of the 3 2nd gen 24v's that I have. My latest project I've been working on is my red 2001 sport truck I thought I'd share. I got the truck a few months ago and immediately began tearing it apart once I got it to the house. The interior was disgusting and falling apart, typical broken dash, it rattled, there was mold growing on the carpet and it even had maggots under some old food. Here's the progress so far. Torn apart within the first 24 hours of owning it The absolutely disgusting old carpet, I was afraid to even touch it without gloves.. How it turned out after scrubbing it and using a house carpet extractor with the hand hose, went over it twice Got the carpet back in, did a slightly darker dye to get rid of the orange discoloration from the coolant dripping onto the passenger side, This was gone over twice and then I hit the passenger floor for a third time while it was in the truck so it's still slightly damp so it's a little bit darker right now. Put some of the interior back in after a vacuuming as much as I could, the back seat looks brand new! Time to work on the old cracked dashboard! The whole dash frame got taken out, stripped, wiped down of any dirt because i'm very meticulous. If I'm going to work on something, I figure might as well do it right the first time. The LMC dash fit perfectly with no issues at all. At this point in time I figured I was already this close to the HVAC box, I might as well pull it out and clean it! If you look at the blend door at the top right, the foam had mold growing on it, no thank you! More dirt, going to have to clean that! Well, I sure was glad I decided to remove the HVAC box, Leaky heater core, dirty evaporator, bad blower motor, and a crumpling blower motor resistor. Yikes! The entire HVAC box got taken apart, cleaned from top to bottom, and reassembled with all new everything! I even went ahead and pulled off all the old foam and put on a new sealer where the old foam was falling apart. Now that the firewall is cleaned up, time for the HVAC box install. Boom! Put in place and ready to go. Remember the old moldy foam from earlier? All gone, and seals perfectly! The midnight grind, literally... By the morning I had everything put back in and was ready to go. All that work and the dash bezel was still cracked, well, until I FINALLY found a wood grain bezel in 100% perfect condition with no scratches or broken tabs! Out with the old, in with the new! The steering wheel bugged me though so I ended up getting a cover for it. As of last night, I believe she's probably the the truck with the nicest interior. Just need to find some power seats and some agate wood door panels. Maybe do a new steering wheel and definitely need to get a 12v outlet that clips into place nicely. Every piece of the interior got pulled out and cleaned, the cup holders got disassembled and cleaned, including the rear one under the console. This interior is immaculate now. Here's a little bonus for sticking around this long. I also did the 4th gen steering upgrade, as well as a Dodge Off Road Track bar and a steering stabilizer. Big difference coming from the stock setup, Once I got all of it in and took it for a test drive, my power steering was leaking and my water pump went out. That's actually coolant dripping on the ground in the last picture but since then has all been fixed! The wife will be a happy camper driving this until I sell my 99'. Thanks for taking a look! It was a lot of work but I don't regret a single moment of it and will do it again in a heartbeat with the way it turned out.10 points- Factory lift pump & After market lift pumps Caution !

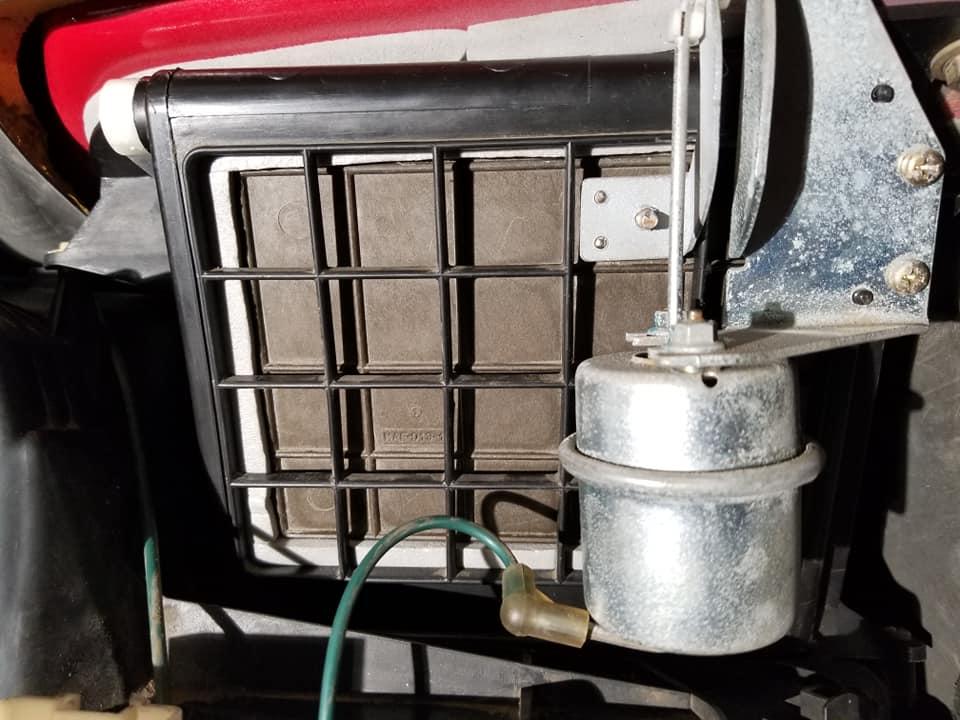

The subject matter has been discussed for years and all diesel enthusiasts/owners know how important it is to maintain proper levels of fuel pressure via the "transfer pump" or Lift Pump for reliable operation. There are many requirements that each owner/operator may wish to achieve in replacing the OE Carter or perhaps making an aftermarket selection. Notably, most have had the rude awakening of a failed VP44 following the failure of the Lift Pump in a too late scenario. The cost of a VP44 compared to the Factory (Carter) Lift Pump is considerable and many of us have learned the hard way. The general consensus among the vast majority is to eliminate the factory OE Carter pump and invest in a robust Class 8 aftermarket system. There are several companies that offer such devices with different performance levels and packaging. Many, come complete with new 1/2" fuel lines, mounting structures, fuel fittings and electrical control harnesses. Some companies offer more modest devices with a budgetary aspect at minimum level. All of this becomes apparent when a conscientious owner/operator begins the research to purchase a new device or system. I for one have stopped reading "Lift Pump" threads because it's so very painful...and I've already seen so many stories of the same old blah blah blah! No, I am not being insensitive to a fellow CTD owner's plight...after all, this is most likely a "new to Diesels" type person. The post is reaching out to the "experienced" diesel enthusiasts for suggestions and perhaps constructive feed-back, prior to making that large investment. Confidence from fellow CTD owners in what they may have purchased or installed goes a long way with the new guy or lady looking for an answer. For just a moment allow me a little latitude...Oh God! Not another Lift Pump story ...Yes but, not what you might think. This will drill-down in a different manor so, please bare with me. The factory OE "Carter" is such a little peanut-whistle why did Dodge do this? The fact is, as many know quite well, the decision was Daimler Chrysler who dictated to Cummins to provide the complete CTD engine package as a drop-in module. Carter's specifications states that, "this pump is to be located within 18 inches of the fuel supply"...it's sad to know these details greatly after the fact. This detail was covered 20 years ago on nearly every diesel website worldwide. This led to the unfortunate degradation of the Carter transfer pumps reputation. In actuality, the Carter LP (lift pump) has excellent design characteristics! At first glance the appearance seems a bit "puny" but, let's look at some of the "not so apparent features"... First of all, Carter is a very large world-wide company who provide a vast selection of produced articles. They also provide excellent technical documentation regarding the application of their products in numerous industrial devices, automotive, marine and aeronautical systems or platforms. Electro-mechanical pumps of this nature, are just a single product that they produce... In our application, CTD's are at first, supplied copious amounts of diesel fuel at acceptable levels to operate the engine and provide flow-through for critical cooling of the VP44 in return to the fuel tank. This is "how" the designed system was to perform. We know as experienced CTD owners that this was not always the case. Many of us know the error of mounting this little well designed pump nearly 10 feet forward of the fuel supply (not to specification of Carter Inc.) and ask this little pump to draw fuel through a small 1/4" line and....force the liquid through "banjo-bolt" fittings as delivery to the VP44? Wow...it's an unreasonable expectation for an electro mechanical pump, that most likely, costs less than $20 to produce in the Philippines. None the less, how many of us have had the occasional chat with a CTD owner (who knows nothing) that tells you they purchased the 2nd Gen new, he has 187K miles and has NEVER replaced the VP44 (he doesn't know what a VP44 is...you just taught him the word) and NO...he has never put a fuel pump into his truck! Yeah ! You know what I'm talking about ! How can this be ? Well...I guess some folks are a lot more lucky than I am... heck...this guy doesn't even know about 2 Stroke for lubricity,... credit our GodFather @Mopar1973Man This photo is well known as a starting point. Also, a depiction of what Cummins had to do to appease Daimler Chrysler's request of a "drop in module" CTD Okay...what is "a well designed pump"... even if it is not mounted correctly? At Carter, where they have been doing this longer than any of our familiar after-market LP suppliers... please note: 1... A fully enclosed hermetically sealed electro-machanical device that allows the liquid fuel to act as a cooling medium and fully immerses the active armature of the 12 volt DC motor to never exceed the temperature of the supplied liquid (diesel fuel)...because it is "airless" (hermetically sealed) there is no ignition to cause flammability. It's liquid cooled ! 2... The entire body or "encapsulation" as hermetic, provides absolute closure or isolation of the motor-brushes as they kiss the surface of the armature in run condition. This is very important as a DC (direct current) motor with carbon pile brushes act as a wild uncontrolled sparking noise source generator !!! This is a normal phenomena of any analog DC brushed motor. A given manufacturer of brushed DC motors, depending on purpose, will take steps to "silence" the electrical (RF noise generation)...the term "purpose" needs clarification... "if the motor is a "CCS" continuous commercial service (runs all the time) then, additional electronic filtering or "shunting" of the armature must be provided. 3... Carter Inc. employs RF Engineers (BSEE graduates minimum) to accomplish technical requirements when contracted specifications are to be adhered to for final product production. An expensive platform in any industrial production would have a string of engineers along with design engineers specking' components or assemblies that will be encapsulated within the finalized product. This occurred in "our" beloved CTD's with electro mechanical LP's....the Carter is "RF quiet" for continuous run condition. Let's examine the electronic terminals of the Carter LP Note: The plastic weather-guard assembly directly attached to the full metal housing that contains the + & - 12 volt DC ! 4... This connection point provides the direct current to power this LP. I wish you to fully understand what you're looking at. As viewed you'll note "both Plus+ and -minus" is provided at this connection point. You must also NOTE, the + and - are arriving directly from a single "pair" connection of both + & - .... I know you'll think I'm stating things "twice" and I want you to know this is an attempt to be a "balanced" feed. The housing of the pump is fully DC grounded when it is attached to the mounting bracket. In a "balanced" feed the "minus" or "negative" is NOT directly at chassis ground...it is merely + and - of the source (12 volts DC in our case) the body of the pump IS directly grounded but, the "source" is isolated from the pump body. Put your Ohm meter on either terminal and touch the pump body....there is NO direct DC continuity in a "balanced" source. This is a sexy way of making things very "quiet" electronically. Professional audio studios are fully balanced systems using "Cannon" connectors with three terminals. One is "plus" Two is "minus" and Three is "shield ground"....hence, balanced and NO Hum or Static noise. (Hey...those guys at Carter make a quiet pump...it's wimpy but, damn quiet) Okay...now let us examine what is going on internally on the back side of the connection point. A careful surgery, with hack-saw in hand, to remove the hermetically sealed body cover and expose the multi-octave filter or "shunting" design of this Carter LP. The double sided epoxy circuit board with modern surface-mount chip capacitors is excellent. This board is located directly at the input of the 12 volt source with virtually zero component lead length (surface mount) to provide shunting of the make and break contact that the brushes are doing directly at the armature when in "run" condition. This DC motor is virtually by-passed or shunted for any RF noise or "spiking" all the way passed 450 MHz! NOTE ! I did say "spiking" or should I say... "ripple"... this is a source of nasty "ripple" directly connected to the entire 12 volt DC rail of our beloved CTD's Quality engineering of analog DC motors remove such garbage before it is introduced to devices such as aircraft, fighter jets, military assault platforms, nuclear submarines and civilian automobiles. There are many preferred after market suppliers of fuel pumps or systems available and many are quite note worthy when it applies to providing solid reliable fuel flow. Many of these platforms exceed the requirements in "fuel flow" for the average diesel enthusiast. Sometimes choices are made because the owner has future plans of building enhanced performance characteristics. Some choose additional GPM for the insurance of added cooling by the "return flow" system design. All of the after market manufacturers of the upper end platforms do this with ease and price the devices accordingly. Caution in selecting any device that may cause unknown after effects in any mobile platform. The CTD 2nd Gen, is something I've looked at carefully for many years and I've made concerted efforts to correct some electrical over sites for the betterment of these noble platforms. I too have made large investments and the after market LP selections are not cheap. I was exceptionally disturbed when I successfully installed an after market LP system. The extreme effort to correctly and cleanly install the system along with all the cool JIC fittings and complete the project with pride that someone may examine my work was all accomplished. Then I shortly discovered the absolute short comings of my nearly $900 investment. I blamed myself for not test operating the device on a test bench and viewing the horrendous RF interference HASH that took out everything from 500 KHz (just below the commercial broadcast band) to well above 500 MHz. Is this important to you?... It is and perhaps it has not become apparent by the way such broadband RF interference manifests itself within a closed stand alone 12 volt system. To make these statements to you, the reader, let me be clear, I use and own a Hewlett Packard 8921A Digital RF test device, at $24,000.00 ...one must be "a fully certifiable crazy idiot" to have this along with a Tektronix 200 MHz 4 channel scope...and someone asked..."Do you need such instruments to look at $25.00 DC motors"...no but, I'm fully confident in my findings. Let's take a look at the much enhanced DC motor of an after market LP...it is irrelevant as to the manufacturer...they are all the same. This is an initial basic disassembly procedure that needs to be performed. It's very easy to accomplish. Once you have the cookie opened you'll be able to view the end-plate where the carbon brushes reside in their respective holders. Many of these devices and earlier models vary by design in physical form but, they are all the same in regard to an end-plate with brush tube holders. Here is the end-plate removed from a different LP unit and we can see the very minimal by-pass engineering of a single .47 Mfd mylar capacitor directly across the two brushes. Note, the lead length. This is typical of an inexpensive analog DC motor...I'll estimate the average wholesale cost of this to be somewhere around $10 to $15 US dollars. It would vary greatly, according to quantity buying levels. The only capacitor seen here is barley a by-pass or shunt...I'd prefer to call this a carbon brush protector. As the armature spins in normal operation, the "make" and "break" of the brushes riding against the armature where "flame" occurs...this cap is merely removing or dampening the "spark" and aiding brush-life longevity. At .47 Mfd it's really only helping at the lowest frequencies to roll off the RF spiking, also with long leads, transversing the distance between the two brushes does not help with the higher frequencies of this wild free-running spark-gap transmitter. This is a far cry from the excellent by-passing techniques incorporated into the wimpy little Carter device. Let us take a look at the fix procedure to begin " RF silencing" one of these very substantial LP platforms. We can't be as effective as the fully closed hermetically sealed package but, with careful effort you can knock this "ripple hash" down by 40db or better in just this simple step. The procedure above depicts a simple "drill and tap" technique using small machine thread hardware. 6/32 or 10/32 should suffice. You can use what ever hardware is available in your junk box as long as it is small enough to fit into the limited working space. Purchasing a small tap and companion drill at your local hardware store to match your "screw-thread pitch" is very low in cost. The skill required to do this is modest, just take your time and carefully hand-cut your threads gently. The cast aluminum end-caps are very easy to drill and tap. NO 9% IPA's should be consumed prior to drilling! Keep your hole straight and pay attention to the "depth" of your drill. With the armature removed you can "eye-in" an approximate location for the mounting hole to accommodate the miniature "lug"...this is where you make an accurate decision of the "angle" for the lug's contact arm to avoid contact with a spinning armature in "run-mode". You must also consider component "lead length"...keep this EXTREMELY short...it will be like working on a Swiss watch in confined space. NOTE: You must loctite your threads! This procedure is introducing component count within a very critical area...errors in loose components will be catastrophic !!! You will make NO errors here! Sorry...my photo is fuzzy. The photo below is zoomed-out for examination of component placement within the end-cap structure. It is tight but, it is precise and highly efficient. This depicts component selection: two each .1 Mfd silver Mica 100 volt dipped packages. I happened to have these in my junk box and standard miniature ceramic caps would also suffice. This completes the "critical" internal modification to initially "RF silence" the armature brush contact event point. I buy electronic components/parts from DigiKey or Mouser...these two capacitors will set you back about 30 cents each...your shipping cost will be ten bucks! Boy...I miss those cheesy little Radio Shacks. It was so convenient to buy little things like this for little money within my own community. Times have certainly changed. Now, carefully reassemble your enhanced LP device and mount it into it's operational nest on the vehicle. The photo below is the final step in this procedure. Again, this shunt capacitor is a .1 Mfd Orange drop package rated at 100 volts. I do prefer this package over standard Ceramic disks under the hood within engine compartments due to heat stress. These maintain tolerance over an extremely wide temperature range. The shortest leads possible, again, is the goal...the lead is directly connected to the relay socket where the 12 volts DC is connected through the relay contacts, that when "closed", provides DC excitation to the LP. I could have made these leads shorter but, I utilized the present ground on the firewall for convenience. Insert the relay back into the socket. This now completes the entire procedure. The monetary expenditure amounts to less than $1.00 for the capacitors. The time involved is substantial. The $689.00 plus dollar, advanced LP platforms available should have arrived fully prepared for trouble free installation and operation. The design engineering staff at Dailmer Chrysler would have never introduced an uncontrolled CCS constant run DC motor device into their platforms at any level. Cummins also, would have never allowed a DC pump without qualification standards to be specified for any production platform. The factory OE Lift Pump from Carter is a very under powered volumetric unit and their is no debating that short coming however: electronically it's design is superior in every aspect. The entire hermetically sealed housing acts as a complete Faraday Shield to fully encapsulate all electromagnetic static fields of force. It is a "dead silent" RF void device! This is just an example...all of the after market companies tout their prowess in delivering liquid fuel at astounding levels of performance, be it a stock engine or perhaps an extremely high horse powered competition street killing monster. None of them provide a civilized RF silenced DC motor to prevent "other" electronic automotive control elements from being harmed when operated within the confined structure of the vehicle. Note: not one bit of verbiage regarding the actual DC motor that powers the device! But, it pumps fluid like heck! I so dearly appreciate the flow factors, the filter systems, the mounting structures and comprehensive packages to alleviate all the short comings of my dismal factory transfer pump issues. Knowing well, that I'll never allow my one thousand dollar plus VP44 from ever being fuel starved again, by selecting an aftermarket LP system...only to realize afterwards, that the introduction of this major investment into my vehicle is now causing electronic issues, else where, within the vehicle! The expensive sound systems, vehicle speed sensing systems, erratic operation of TC lock-unlock, cruse control abnormalities, and radio communications equipment. All of these things at one time operated without error, you enjoyed the accurate trouble free aspects of your prized motor vehicle, then...something happened! Being cautious about adding any electronic implement into a trusted vehicle is always prudent. Asking the right questions before hand is always best practice. This information applies to ALL Vehicles regardless of manufacturer Ford, Chevy or Dodge. This article is following additional postings on this web-site...Mike Nelson @Mopar1973Man and Nick @Me78569are struggling to keep this small and independent site operational. I am not affiliated with any supplier or manufacturer...I am a contributing customer who appreciates the time proven and solid information/guidance these two men provide to the diesel community. I humbly share this knowledge with the CTD fraternity with enthusiasm, for the improvement of our platforms...may I ask a very small favor...if you find the information on this site of value could you please consider making a one dollar donation to the site to keep the lights on Thank you, Respectfully, W-T10 points- Installed a Nations alternator - results

10 pointsI try to be proactive towards the maintenance of my truck rather than reactive..... Knowing that the OEM Bosch alternator had almost 120k miles on it, I felt that not only was it probably going to give me DC troubles in the near future but I was also sure that I was most likely experiencing some AC issues as well, especially during the cold morning and hot summer weather. Why I say that....? I've tested my AC voltage before during the summer and it was within "spec", but still I thought the readings were higher than I'd like. So I recently tested again before installing the Nations unit just to confirm and what I got was about .044 during idle. Yes thats acceptable but also understanding that its 35* outside and the engines warm enough that the grids are not cycling, I felt that there was nowhere for the AC readings to go but up. Meaning, as the weather gets warmer and/or the alternator is powering more accessories, the AC voltage reading will only increase. Alternators will produce the least amount of AC at idle with little to no electronics running. But ramp the throttle up to around 2000 - 2500 RPM, turning on every electrical component and the readings will always increase as the diodes work at converting. I saw that the last time I tested it in the summer so I felt I'm justified in replacing before problems arise. Plus I noticed a considerable amount of red brush dust on the tensioner pulley (seen in the picture) which reassured me that it was getting old. So I've decided to replace it. Exploring my options, they are as usual..... To either rebuild my current one, get an over the counter "lifetime warranty" parts store unit and hope for the best, or look for one of the few high dollar units available out there in the aftermarket world. Well given money is always a variable, I chose to go with the Nations unit I've heard good things about. Not only are they priced what I consider to be reasonable for what you get but they're also American made. Plus if I have trouble, I'd rather deal with Nations than deal with either Autozone, NAPA, O'Reilly, etc... and risk delicate electronics on this truck. Yes, I could have had it rebuilt but I'd still have an alternator that may or may not generate more AC than I'd like because of the windings and diode count, but I'm sure I'd probably have battle with the small shop explaining what I want and why, since most places are more concerned with DC output rather than what the AC voltage readings are. This is the one I opted for. 180 amp, hairpin wound, 12 diodes, and uses the stock pulled size. http://www.nationsstarteralternator.com/180-Amp-HP-High-Output-Alternator-for-2000-Dodge-p/13874-180-hp.htm Just to be clear.....what I was experiencing with the OEM alternator was the norm and had been this way for years. That said, typically the volt gauge in the cold mornings would do as described: Turn key ON, gauge drops to the lower portion of the "normal" range. Start engine when WTS light turns off. Gauge immediately drops back down to the lower portion of normal as the grid cycles on again. Gauge starts to climb rapidly as the grid cycles off. Seconds later the grid cycles on again and the gauge dips down to the lower portion of normal. This back and forth takes places for a few minutes depending on the ambient temperature. And when it does, the engine clearly lets me know that the grids are cycling by either making the tell-tale noise of loading down from the alternator drag, and/or I can get a slight momentary idle lope only to immediately regain regular idle. The lights dim considerably as well and the volt gauge generally reaches just a tick over 14 volts when its completed the event or I drive off. Well after the install of the Nations unit this is what takes place: Turn key ON, gauge drops to the lower portion of the "normal" range. Start engine when WTS light turns off. Gauge does NOT drop back down to the lower portion of normal as the grid cycles on again, but rather remains up around 14 volts. Gauge moves a tad higher than 14 volts as the grid cycles off. Seconds later the grid cycles on again and the gauge drops no lower than 14 volts. As before, this back and forth takes places for a few minutes depending on the ambient temperature. But this time the engine does NOT react the same but rather hardly lets me know that the grids are cycling. There is no tell-tale noise of loading down from the alternator drag and I seemingly had no slight momentary lope during that moment either. I cant say about the lighting at this point because I havent driven it during the night since the new alternator was installed. But I'm going to guess that they will not dim nearly as much given that the alternator appears to be cranking out more amperage during idle while creating less load on the engine. I also tested the AC voltage as soon as I installed the Nations unit, while during the same cold weather, and saw about .020. I'll be testing it some more as the weather warms too. Lastly, I would say that of the few times I've driven it since the install the engine has slightly better manners during the cold weather. This only further supports the understanding that these trucks are VERY susceptible to electronic anomalies and the alternators are absolutely something to pay attention to.10 points- 47RE fluid temp?

10 pointsA lot of good info here... I, personally, consider anywhere from about 150-180 degrees F to be an ideal operating temperature for an automatic transmission. Many run cooler than this, which is really no problem. Some run hotter than this, which is not a big problem (to a point, obviously), as long as the cooling system is able to bring it back down when the "heat-inducing" conditions are removed. When you're working the transmission, it's going to make heat. There's no getting around it. As long as that heat can be managed, life is good... I am a big proponent of leaving the OEM heat exchanger in place. It is technically called the "torque converter cooler" by Chrysler, and that's exactly what it is. When you're working your converter hard, the fluid temps coming out of it can be downright scary! The heat exchanger does a fantastic job of knocking that temp down to where the air-to-fluid cooler (auxiliary cooler) can manage it effectively. Does the heat exchanger heat cool fluid? Yeah, some... But not enough to worry about, and the benefits when the fluid is hotter than the coolant cannot be overstated. I highly recommend placing the temperature sender in the pan, as many have mentioned. The Low/Reverse servo pressure tap is where it ends up a lot of times, but there's not really any fluid circulating there. It just kind of gives you a reading of the temperature of the case right there. Better than nothing, yes, but not ideal. Plus, if you put a billet servo piston in the Low/Reverse, the sender will interfere with its operation. I have found, through a bunch of recent 3rd Gen testing recently, that the OEM temp sensor in the transducer seems to read high...sometimes by quite a bit. If you have a scanner or monitor that is simply pulling transmission temp information off of the data stream, I would verify its accuracy before I got too worked up about anything. A recent customer was concerned about his 190-200 degree indicated operating temperature (Edge CTS2). Testing this info against a known good gauge (and also an infrared heat gun) showed that it was reading about 25-30 degrees high. A new transducer brought things much more in line, but it still read high. Take it with a grain of salt until you verify its accuracy. Running a deep pan is never a bad idea, although don't look to it to solve an overheating issue. More fluid is a bigger heat sink, and does tend to lower operating temperatures with all other conditions being equal. But it you have a heat issue, more fluid will have a small effect on things. The main reason that I like to run an aftermarket pan is to strengthen the case, as @jlbayes mentioned. The bottom of the case on a 46/47/48 RE transmission is wide open, and case flex can be a pretty big deal when the torque numbers reach the stratosphere. A good aluminum pan really helps...probably more than you would think. There are many good pans on the market. I have used Goerend, Mag-Hytek, LPW, B&M, and probably others as well. All are good quality pieces, and do their job well. I will say that I have never been very impressed with Derale pans. No offense to those who have them, but they are really quite flimsy when compared to an OEM pan, and offer no additional case rigidity, as was mentioned. I have been through some ugly wars with Derale pans trying keep them from leaking as well.10 points- Prayers Please for MoparMom

10 pointsThank you,,,,I'm moving right along. God helped the snail reach the ark so we are moving right along at the pace HE has determined for me, I also give new meaning to our Mopar t-shirts, Achieve your destination!!!!Life has so very many surprises.,,,setbacks too,,,but these are our challenges. I'M GOING FOR IT!10 points- Truck stolen

10 pointsSitting at home waiting on the insurance adjuster. I'm glad she's home safe!!10 points- Fed up

10 pointsDont worry guys..... I understand some of our well minded leaders have it all figured out. Apparently college tuition will be free and society's problems will be fixed. Smart phones are government paid. No one will have to perform any tedious manual labor any more and everyone will be making triple digits with huge retirement pensions, and bonus.....all medical will be free too boot. We'll be able to use in any bathroom we choose, wear anything that fits (if you feel like wearing clothes). We can have sex with anyone and anything we desire, and marry everything including inanimate objects and fictitious beings. There will no longer be issues with high priced fuels as municipal transportation systems will readily take us wherever we need to be in electric buses or bullet trains pointed in every destination. Drugs will never be a problem again as all of them will be legal and you'll be able to get them and do them at your leisure. The police system will no longer be needed since no longer breaking the law is a problem as everything is now OK. Guns?.....who needs guns in a place like this because our world will be a FREAKING UTOPIA!!!!! And yeah, EVERYONE is welcome too. Not sure where all the money will come from and I'm not sure about much of the details, but dont bother asking questions..........because thats not the point.10 points- Explain to me how the 47re shifts

10 pointsYou basically have two different pressures at work in the VB when determining upshift and downshift points. First, there is governor pressure, which is determined by road speed. Early transmissions (46RH, 47RH) used a mechanical governor on the output shaft, and the newer RE transmissions replaced the mechanical governor with the governor pressure solenoid/transducer setup that we all know and love. The PCM generates the governor pressure electrically via the solenoid, and monitors the governor pressure via the transducer. Either way, the faster you are driving, the more governor pressure... Second, you have throttle valve, or TV pressure. This pressure is determined by throttle position. When you press on the throttle, the TV cable pulls on the lever at the transmission, which rotates the TV lever shaft, which then presses on the end of the TV plunger in the VB. The plunger then loads the TV pressure regulator spring more heavily which, in turn, increases TV pressure; the more throttle, the more TV pressure... There are two shift valves in the VB that use governor and TV pressure to determine shift points; the 1-2, and the 2-3 shift valves. (The 3-4 shift valve and TCC lockup valve are controlled separately by the PCM via solenoids and do not use governor or TV pressure to determine their shift points.) At each shift valve, governor pressure acts on one end of the valve, constantly trying to stroke the valve to the "upshifted" position. At the other end, there is a spring holding the valve in the "downshifted" position. In addition to the spring, TV pressure also acts on that same end of the valve, assisting the spring in holding the valve in the "downshifted" position. When you are at a standstill, governor pressure is at a minimum (basically zero psi) and the shift springs hold their valves in the "downshifted" position - first gear. As you take off from a stop, governor pressure begins to rise, acting on the end of the shift valves. If you are light on the throttle, TV pressure is very low and governor pressure quickly rises to the point that the force of the 1-2 shift spring at the other end of the valve is overcome and the 1-2 shift valve strokes, commanding a 1-2 upshift. The transmission is now in 2nd gear... If you are heavier into the throttle, TV pressure assists the spring with greater force, making it necessary for governor pressure to build to a higher level before the force of the spring AND the hydraulic force of the TV pressure acting on the end of the valve to be overcome. This is how the transmission holds each gear for longer when you are heavier into the throttle. As you continue to accelerate, governor pressure continues to rise until the 2-3 spring force (and whatever level of TV pressure that is acting on the 2-3 shift valve) is overcome and the 2-3 shift valve strokes, commanding a 2-3 upshift - 3rd gear... When commanding a downshift, you press on the throttle harder and TV pressure rises. When TV pressure rises to the point that (with the spring's help) governor pressure can be overcome, the valve will stroke back to the "downshifted" position and either a 3-2 or 2-1 downshift is commanded, depending upon which gear you were in. If the throttle application is abrupt enough, and TV pressure rises quickly enough, both valves will be stroked to the "downshifted" position nearly simultaneously, and a 3-1 downshift will occur. This is kind of a simplified explanation of what goes on in the Dodge valve body for 1st - 3rd gear. As I stated earlier, 4th gear (OverDrive) and TCC are controlled directly by the PCM via their respective solenoids.10 points- Another tidbit about MPG's.

10 pointsI did some more measuring and testing for the MPG crowd. Before I start I will say that I just verified my SGII and its right close to being on the money (off by 0.2 gallons). I'll assume that a slight error between the ScanGauge and the fuel pump. Now I my truck conditions are Edge set for 5x3, IAT fooled to 143*F, Engine coolant varied from 188*F to 197*F, winter fronts still on. Actual weather was high of 65*F (actual IAT was ~90-105*F) Now since I was on I-84 down in southern Idaho today I figure I open the beast up and let it fly low for once. So I set the cruise for 75 MPH and reset the current MPG counter and measure for about 20 miles of highway. I was pulling roughly ~13 MPG. Then after shopping in Nampa, ID and got back on the same stretch of highway again and set my cruise this time for 65 MPH then reset the ScanGauge II again and measured about 20 miles of highway again. I turned out ~18 MPG. Then even with all the playing driving fast and slower I still pulled in the yard with a total of 22 MPG. So from this rough measurement I found that roughly for every 10 MPH above 55 MPH I lose roughly 5 MPG. This is calculated numbers here. According to Google Maps its 300 miles round trip what I drove. Time to travel distance 300 miles / 55 MPH = 5.4 Hours 300 miles / 65 MPH = 4.6 Hours (0.8 hours less than 55 MPH) 300 miles / 75 MPH = 4.0 Hours (0.6 hours less than 65 MPH, 1.4 Hours less than 55 MPH) Amount of fuel consumed 300 miles / 21 MPG = 14.2 Gallons (@ 55 MPH - not a true 55 MPH because of testing) 300 miles / 18 MPG = 16.6 Gallons (@ 65 MPH) 300 miles / 13 MPG = 23.0 Gallons (@ 75 MPH) Cost difference @ $4.019 Gallon (which I paied for) 14.2 Gallons x $4.019 = $57.06 16.6 Gallons x $4.019 = $66.71 ($9.65 more than 55 MPH) 23.0 Gallons x $4.019 = $92.43 ($25.72 more that 65 MPH, $35.41 more than 55 MPH) Another tidbit. I get the same MPG's towing my RV at 55 MPH than I do driving empty at 75 MPH. Also the fuel consumption rate at 75 MPH is just about the same as climibng a 5% to 6% grade at 55 MPH. This shows that amount of rolling resistance and wind drag differences between 55 and 75 MPH.10 points- DTT Assassin Mechanical Fuel Pump.